Plate type evaporation air cooler

A technology of plate evaporation and air cooler, applied in the direction of water shower cooler, direct contact heat exchanger, heat exchanger type, etc., can solve the problems of low heat transfer efficiency, dust accumulation, heavy weight, etc., and achieve enhanced heat transfer , Improve the effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

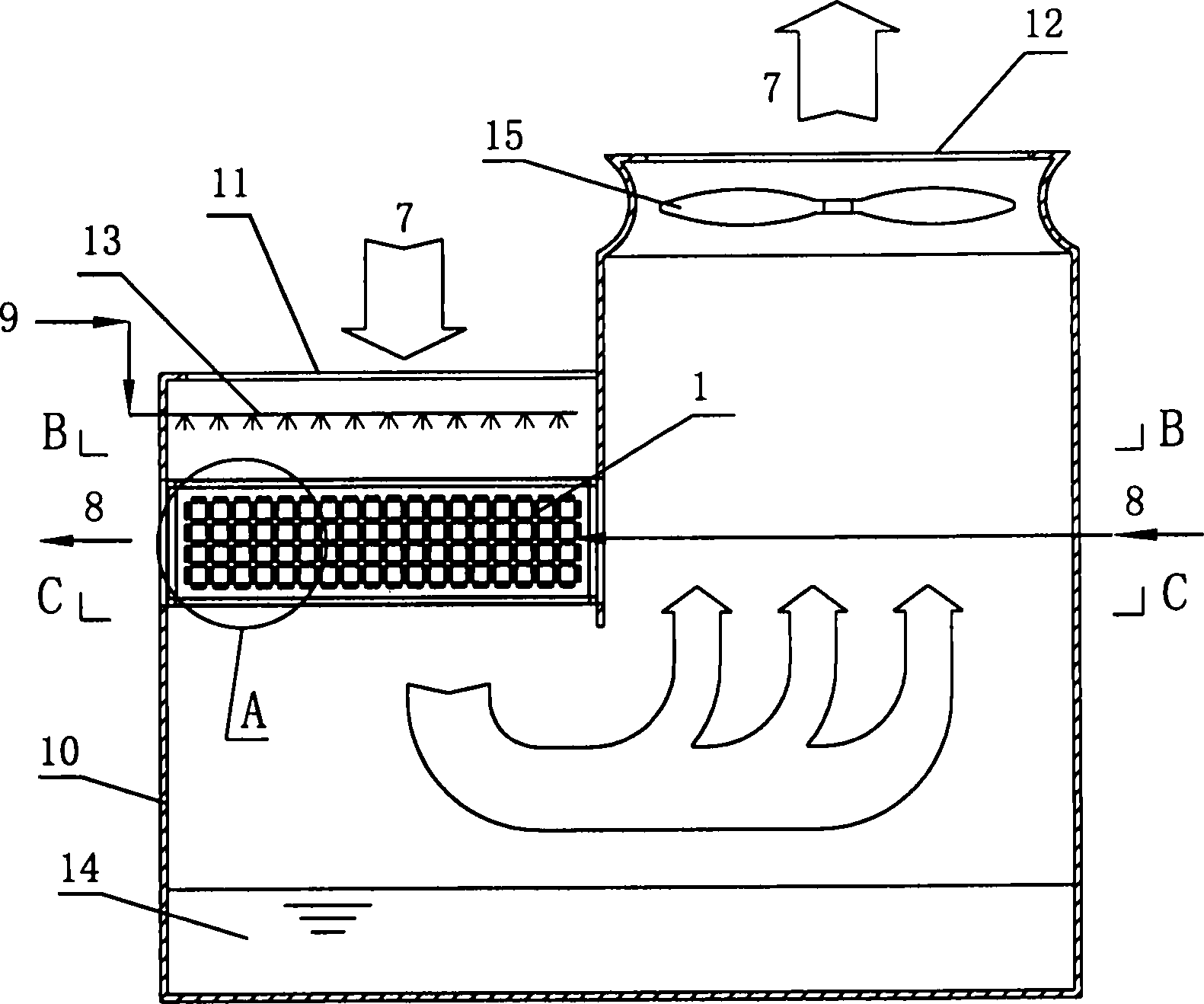

[0043] Drawing number 1. Plate bundle 2. Plate tube

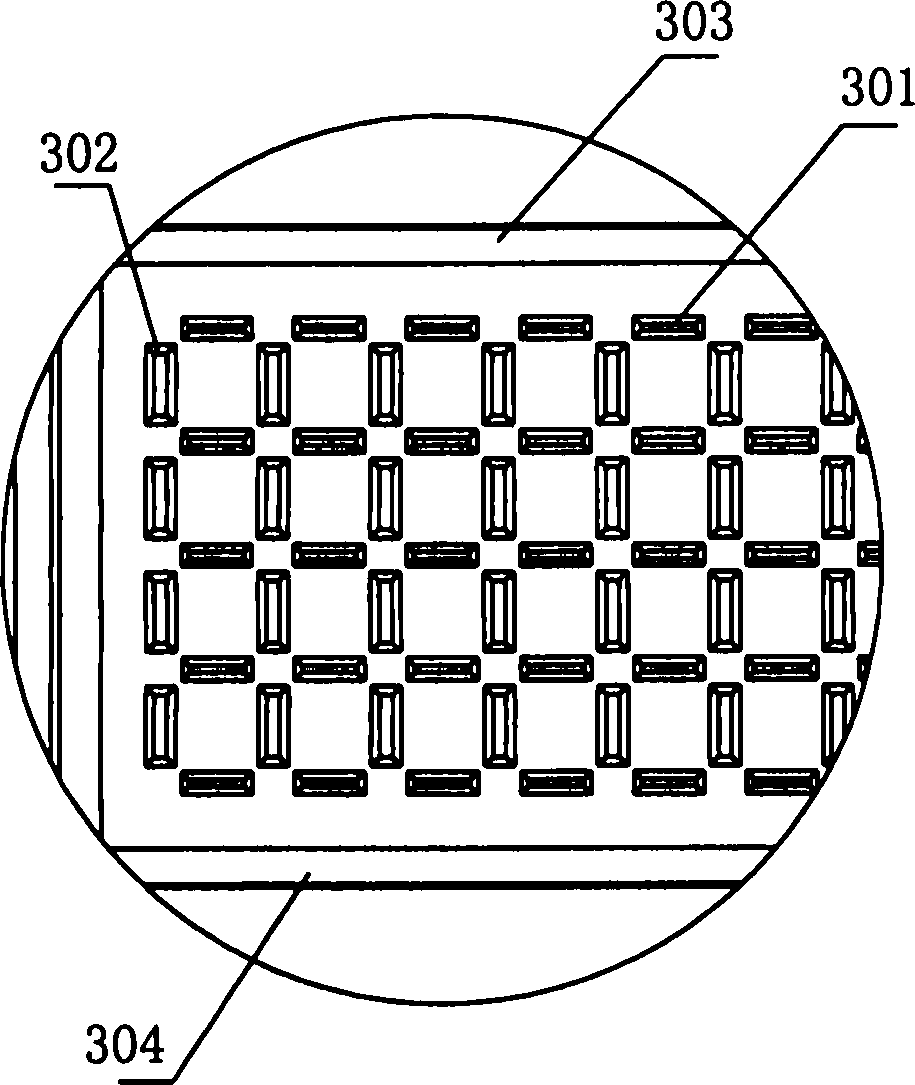

[0044] 3. Plate 301. Row corrugation 302. Column corrugation

[0045] 303. Horizontal edge 304. Horizontal edge 305. Longitudinal edge 306. Longitudinal edge

[0046] 4. Plate 401. Row corrugation 402. Column corrugation

[0047] 403. Horizontal edge 404. Horizontal edge 405. Vertical edge 406. Vertical edge

[0048] 5. Horizontal flow channel 6. Longitudinal flow channel 7. Arrow 8. Arrow 9. Arrow

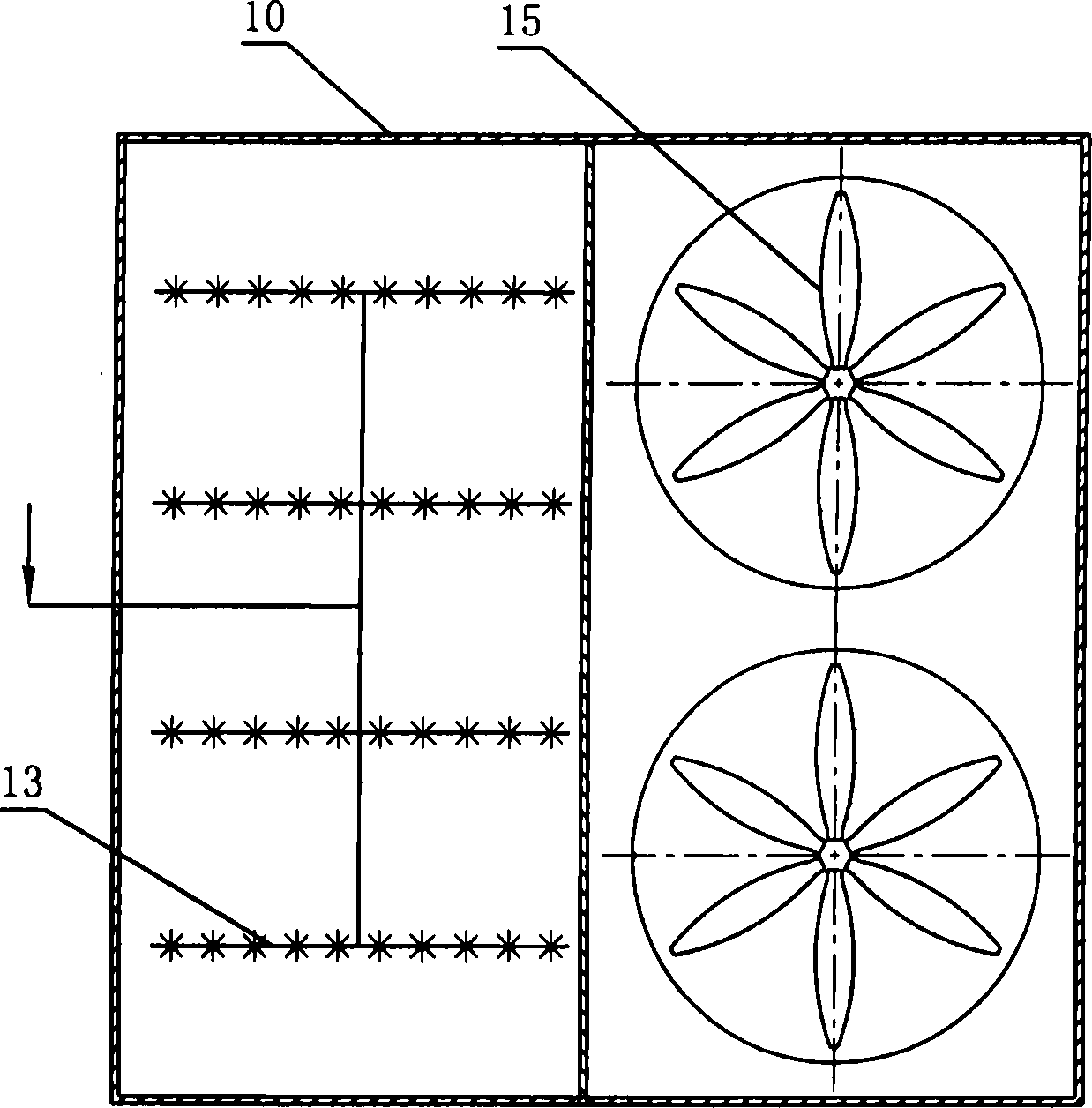

[0049] 10. Cabinet 11. Air inlet

[0050] 12. Air outlet 13. Spray device 14. Inner cavity 15. Induced fan

[0051] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the present invention is a plate type evaporative air cooler, including a box body 10, the top of the box body 10 has an air inlet 11 and an air outlet 12, both the air inlet 11 and the air outlet 12 are connected with the inner cavity 14 of the box body 10, and the air inlet A plate heat transfer element is installed at the tuyere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com