Impeller for compressor

A compressor impeller and impeller technology, applied in the field of compressor impellers, can solve the problems of increased loss at the outlet of the impeller 102 and reduced efficiency of the diagonal flow compressor 200, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

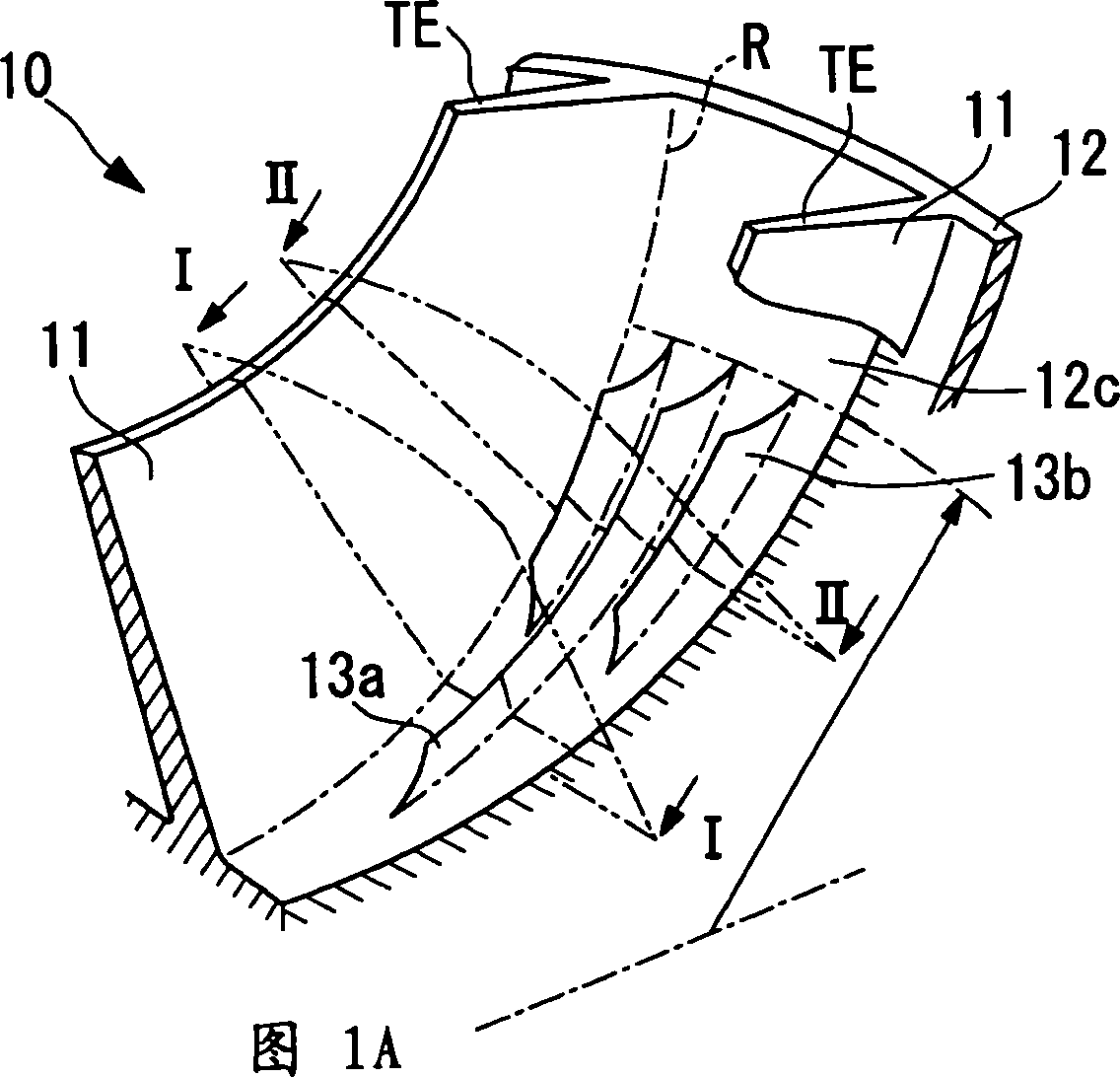

[0086] Hereinafter, referring to Fig. 1A- Figure 1C A first embodiment of the compressor impeller of the present invention will be described. A specific example of the case where the impeller of this embodiment is applied to a centrifugal compressor is shown.

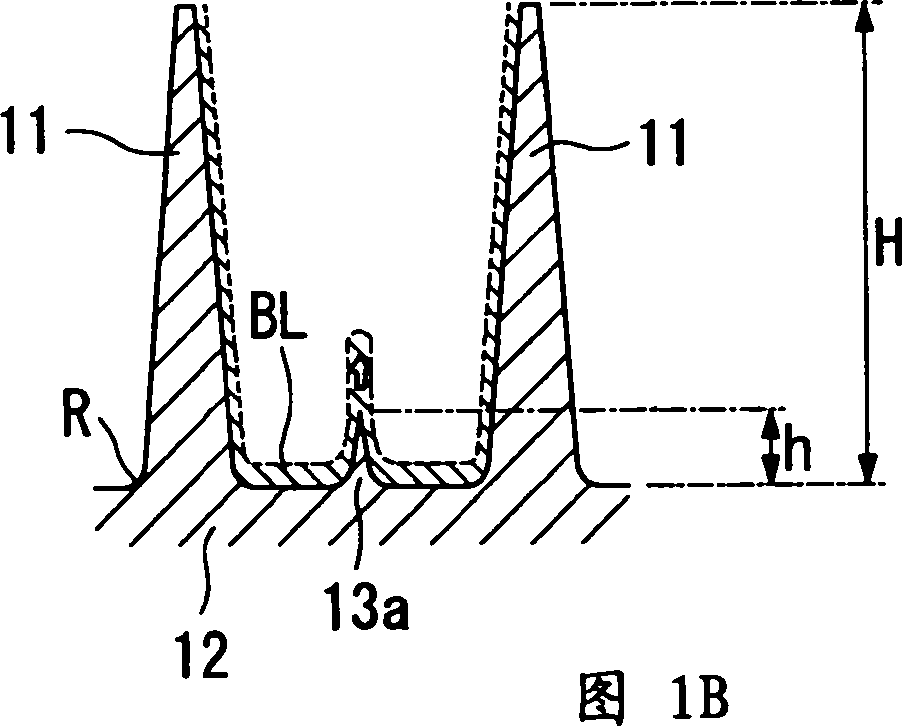

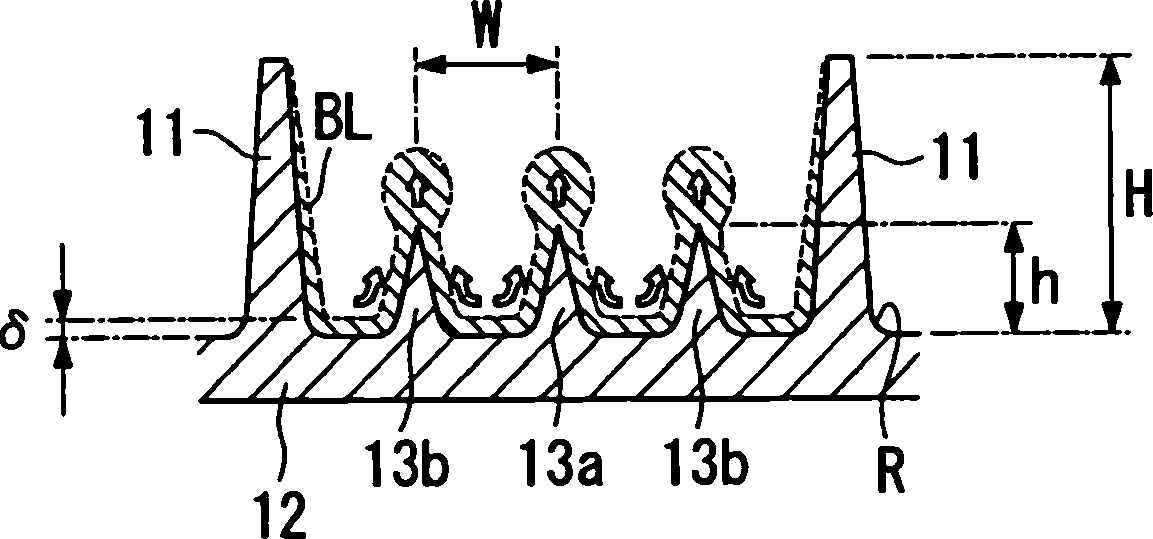

[0087] FIG. 1A is a perspective view of main parts of the impeller 10 according to this embodiment, and the end of the impeller 10 on the inlet side is omitted. In addition, FIG. 1B is a sectional view taken along the line I-I of FIG. 1A , Figure 1C It is a cross-sectional view taken along the line II-II in FIG. 1A .

[0088] Figure 1A~ Figure 1C As shown, the main constituent elements of the impeller 10 according to this embodiment include a plurality of blades 11 and a hub 12 disposed on the roots R of the blades 11 .

[0089]The blades 11 are respectively arranged on the surface of the hub 12 such that the leading edge LE thereof is positioned at the small diameter side end 12a of the hub 12, and the trailing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com