Conic hole boring machine with adjustable taper

An adjustable, boring machine technology, used in boring/drilling, drilling/drilling equipment, boring machine/drilling machine components, etc., can solve the problem of limited processing size, low boring bar reuse, tooling Due to the problems of large volume and weight, the effect of compact structure, light weight and low processing cost is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

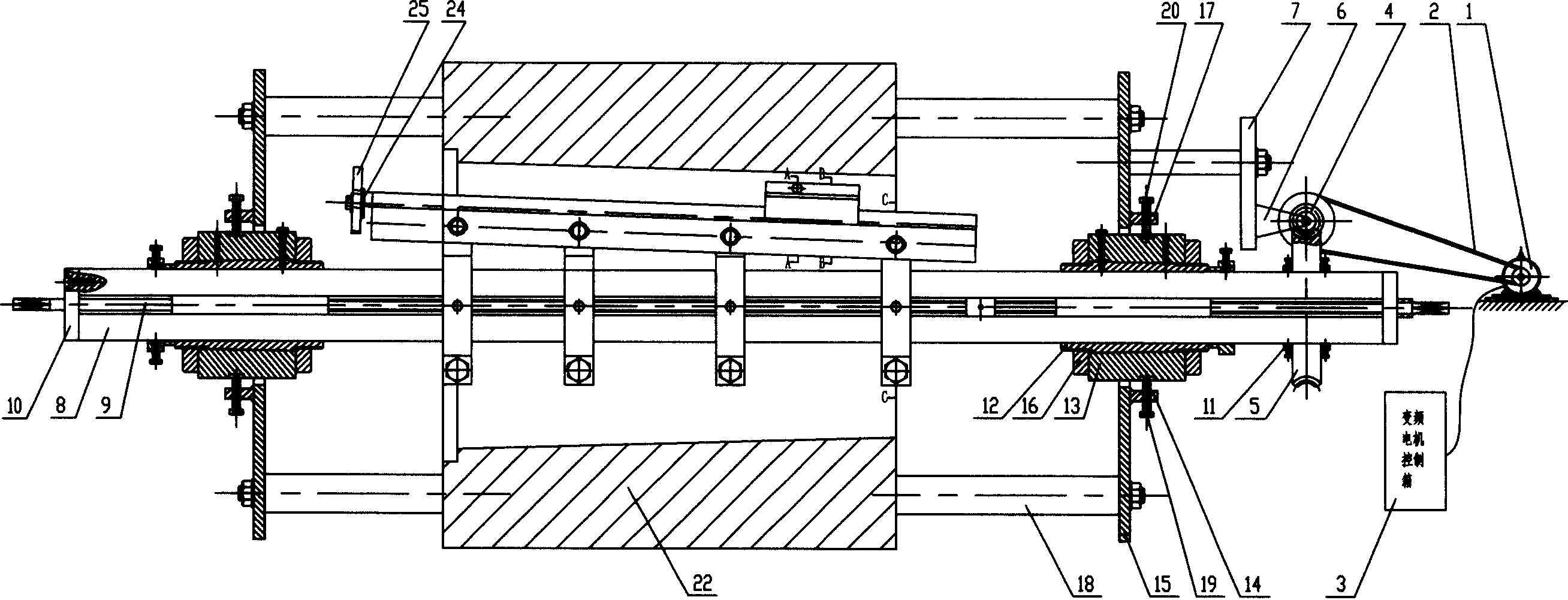

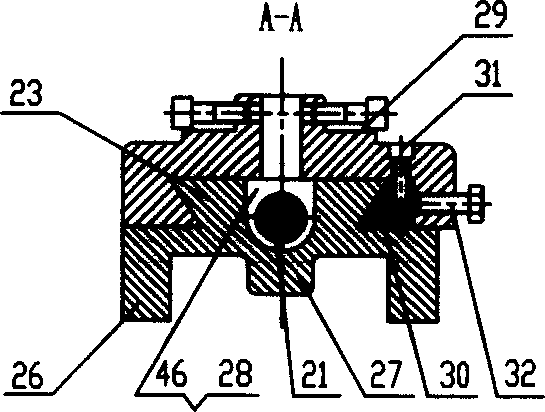

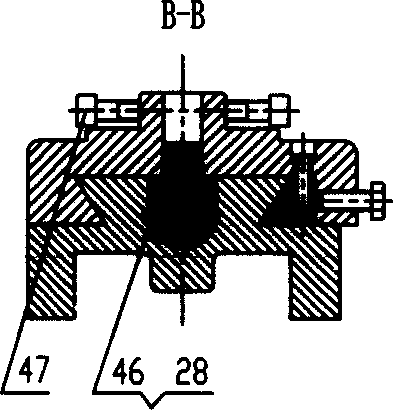

[0026] Taper-adjustable tapered hole boring machine, including drive system, straight boring bar 8, two boring bar support devices, inclined guide rail installation clamp 33, axial feed device, tapered hole processing cutter head 29 and end surface processing tool assembly .

[0027] The straight boring bar 8 is provided with a semicircular groove 9 along the axis, and the two ends of the boring bar are provided with glands 10 on the end face of the boring bar. The drive system includes a variable frequency motor 1, a variable frequency motor control box 3 and a worm gear transmission. The worm gear transmission includes a worm 4, a worm wheel 5, and the worm wheel 5 and the worm 4 mesh. The shaft gear on the frequency conversion motor output shaft is connected with the shaft gear on the worm screw 4 shaft through the belt 2. The shafts at both ends of the worm screw 4 are respectively supported by bearing housings 6 with bearings, and the two bearing housings 6 are fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com