No-fluctuation hot blast stove converting method

A hot blast stove, no fluctuation technology, applied in furnaces, blast furnaces, heating furnaces, etc., can solve problems such as shortening the furnace replacement time, affecting the straight line of the blast furnace, and poor opening accuracy of the pressure equalizing valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

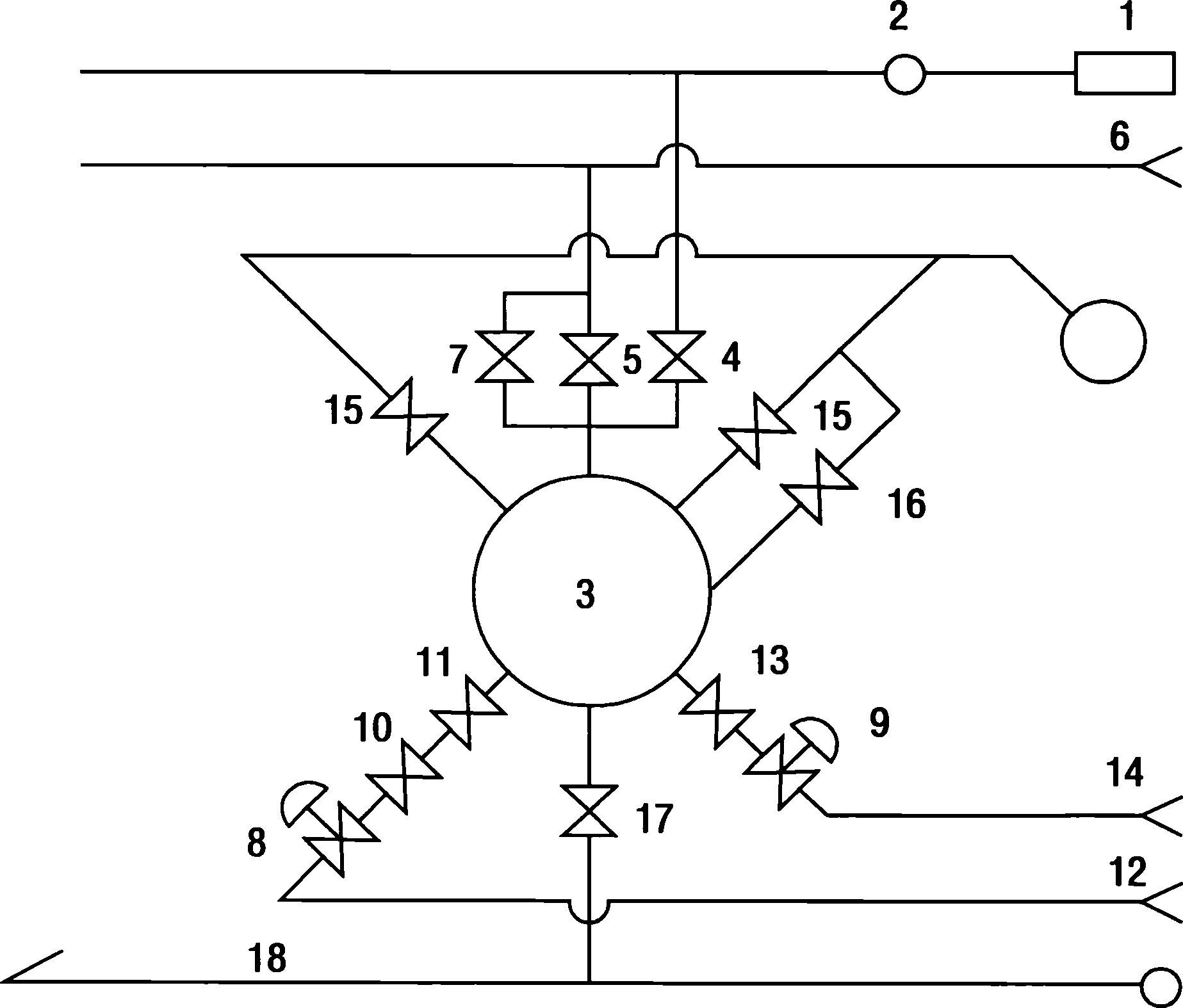

[0010] The accompanying drawing is a flow chart of the process when the hot blast stove is replaced with pressure. The compressed air is drawn from the compressed air bag 1 of the blast furnace compressed air system. Pressure valve 4 is connected with cold air duct 6 after cold air valve 5 . Put the cold air pressure equalizing valve 7 in the normally closed state as a backup. Connect the compressed air equalizing valve to the microcomputer in the main control room, and when the hot blast furnace changes from the combustion state to the air supply state, close the gas regulating valve 8, close the air regulating valve 9, close the gas shut-off valve 10, and close the gas combustion valve 11. Cut off the blast furnace gas 12 entering the hot blast stove, close the air combustion valve 13, cut off the combustion air 14 entering the hot blast stove, close the flue valve 15 (the waste air valve 16 is closed at this time), and open the compressed air equalizing valve 4 (pressuriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com