High strength aluminium alloy wire and rod and their prepn process

A preparation process, aluminum alloy technology, applied in the direction of metal rolling, etc., can solve the problems of not being able to meet the high-voltage transmission grid, and achieve the effects of avoiding repeated investment, improving overall quality, and reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

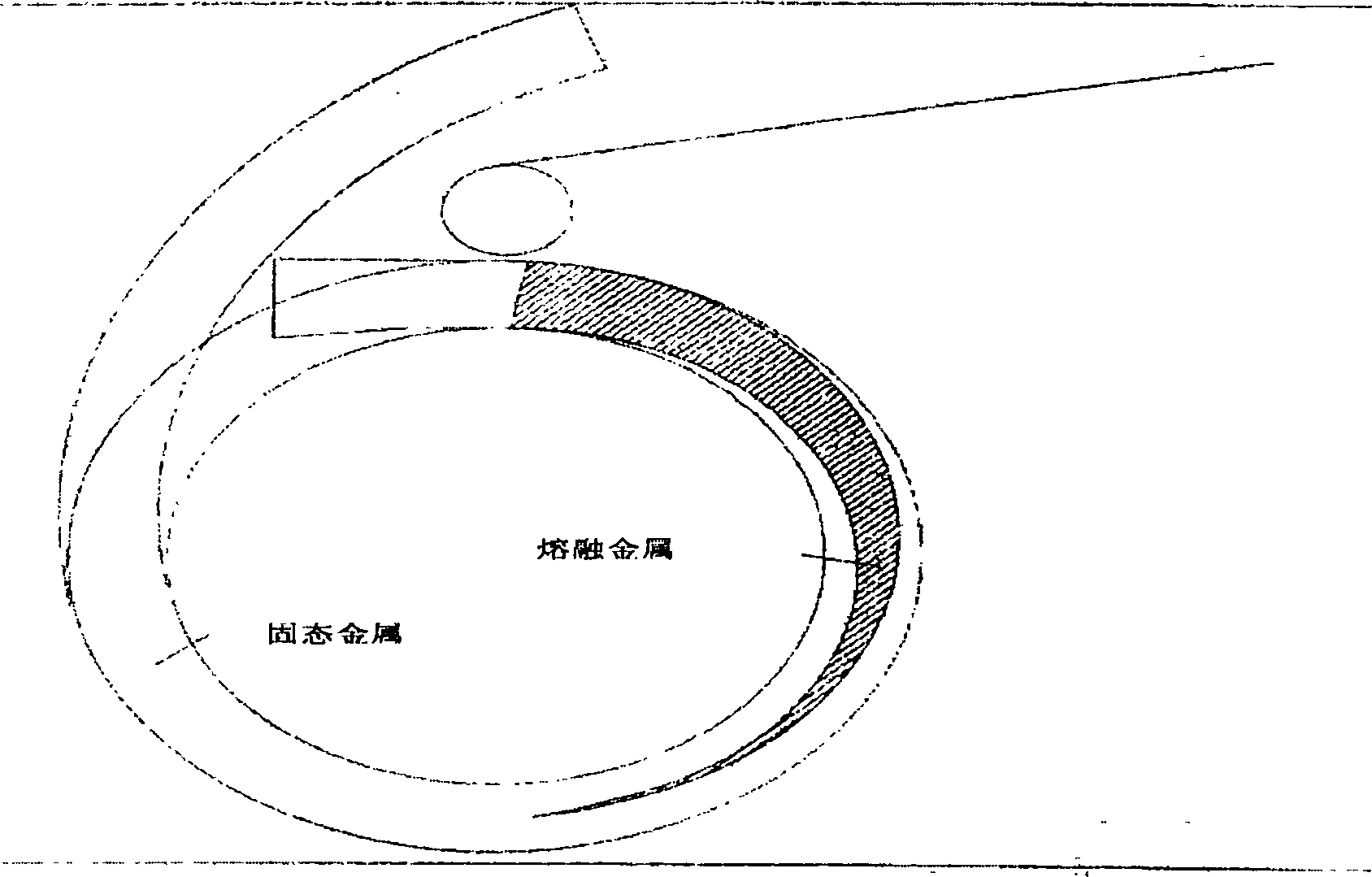

Method used

Image

Examples

Embodiment Construction

[0014] Embodiment of the present invention: high-strength aluminum alloy wire rod, which contains aluminum, iron, magnesium, silicon, copper, zinc, manganese, chromium, boron, titanium elements, the mass percentage of each element is: iron 0.20%, magnesium 0.65% , silicon 0.60%, copper ≤0.10%, zinc ≤0.10%, manganese ≤0.03%, chromium ≤0.03%, boron ≤0.06%, titanium 0.006%, impurity content ≤0.10%, and the rest is aluminum.

[0015] When preparing the above-mentioned high-strength aluminum alloy wire rod, the following steps are included:

[0016]

[0017] The quality of metal magnesium ingots should meet the requirements of GB / T3499-83 standard level two or above, and the chemical composition should meet the requirements in the table below.

[0018] level

[0019] Then add electrolytic aluminum liquid with a temperature of 760-780°C into the holding furnace from the aluminum inlet of the holding furnace to obtain an aluminum alloy melt after melting, and make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com