Thin film transistor, display, liquid crystal display, and method of manufacturing them

A technology for thin film transistors and display devices, which is used in the fields of display devices, wiring, and thin film transistors, and can solve problems such as inability to handle the surface of display panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

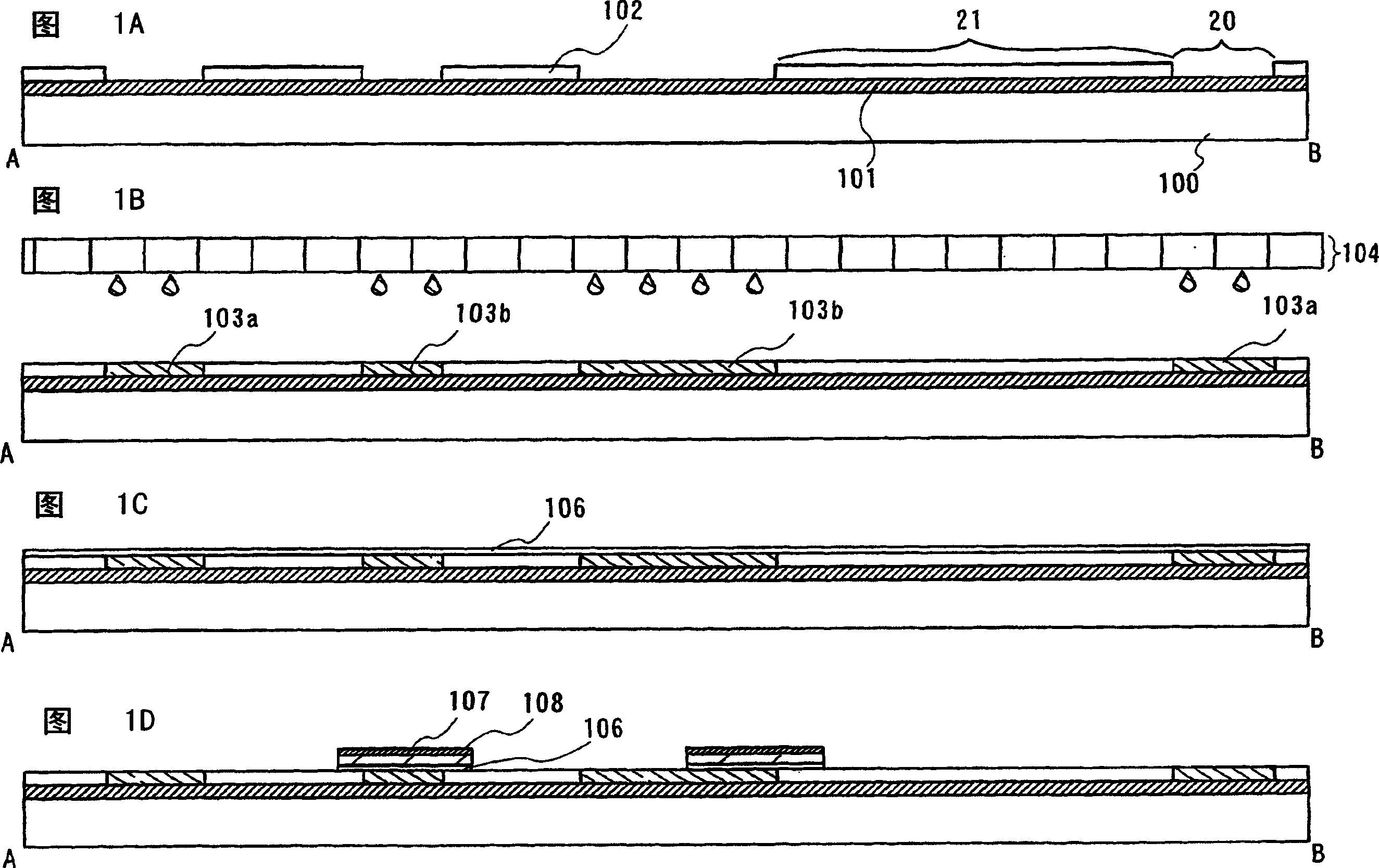

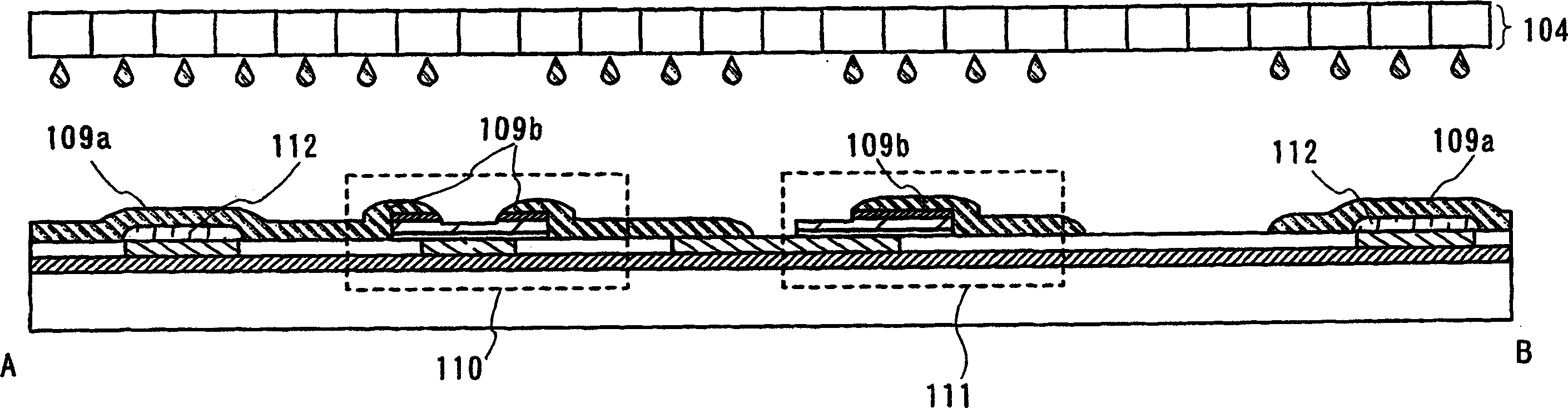

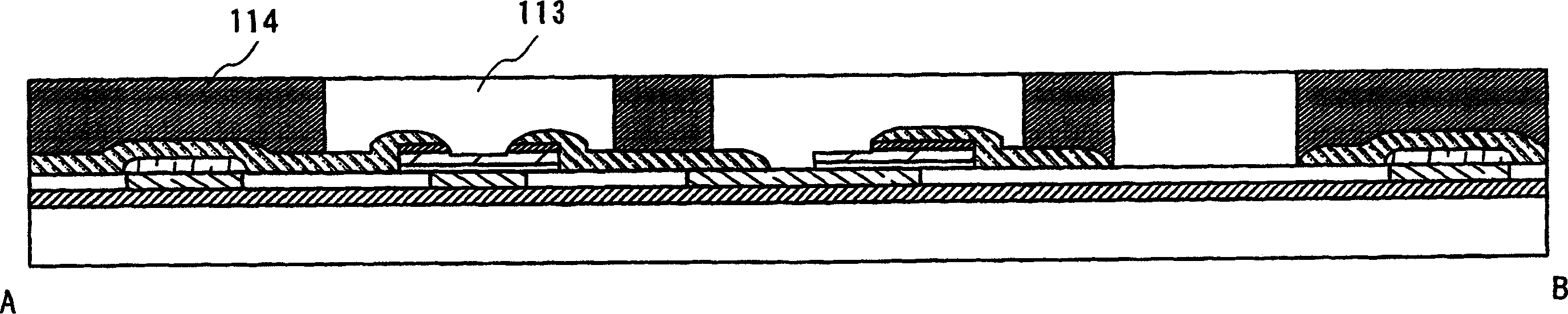

[0118] Embodiments of the present invention are described in detail below with reference to the accompanying drawings. Note that it can be easily understood by those skilled in the art that the present invention is not limited to the following description, and various changes in form and details can be made without departing from the spirit and scope of the present invention. Therefore, the present invention should not be limited to the description of each embodiment mode below. In the respective drawings for explaining the respective embodiment modes, the same reference numerals are given to the same components, and descriptions thereof will not be repeated.

[0119] A TFT has 3 terminals, namely a gate, a source, and a drain; but a source terminal (source electrode) and a drain terminal (drain electrode) cannot be clearly distinguished due to the structure of the transistor. Therefore, when describing connections between elements, one of the source electrode and the drain e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com