All-terrain vehicle sprocket buffer device

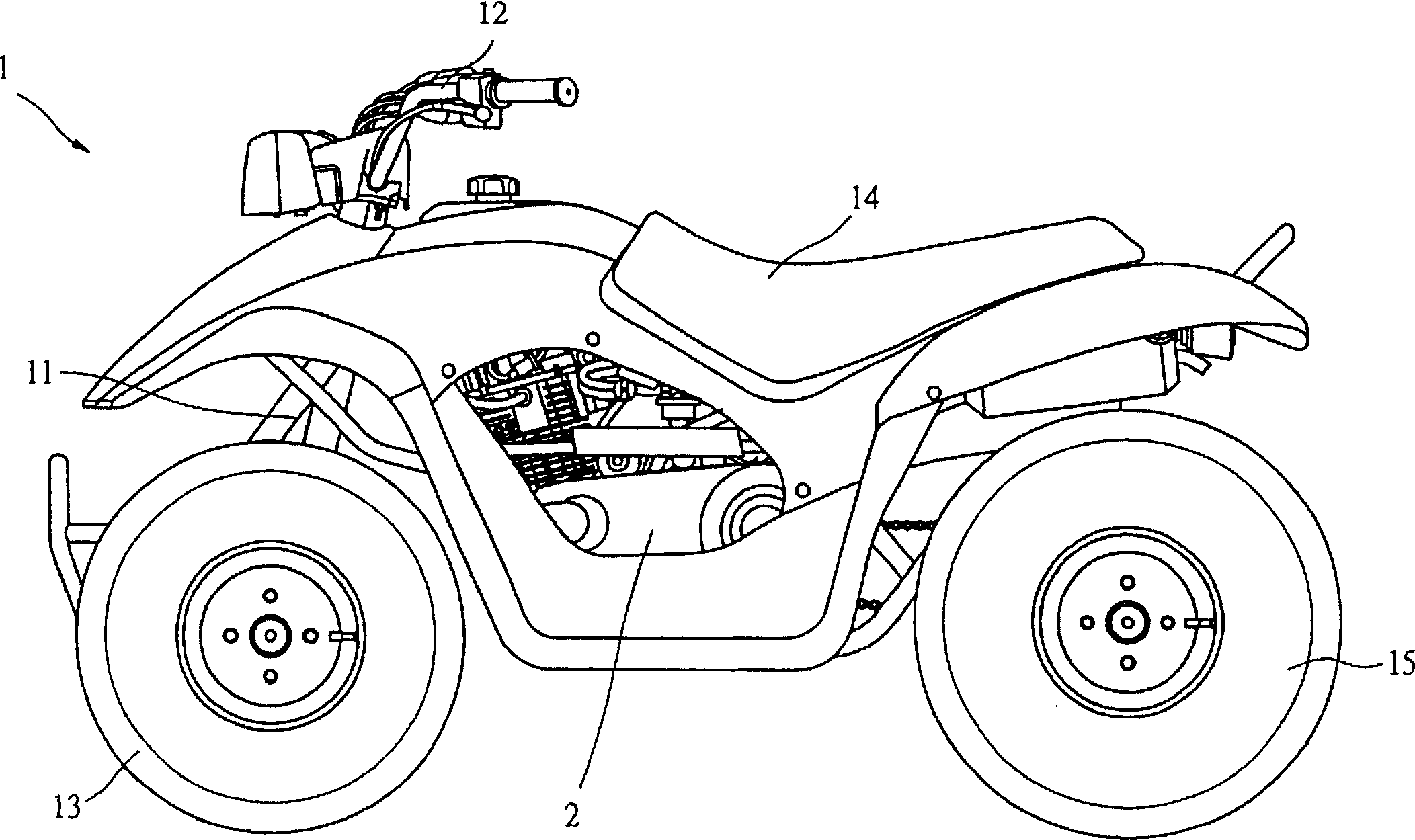

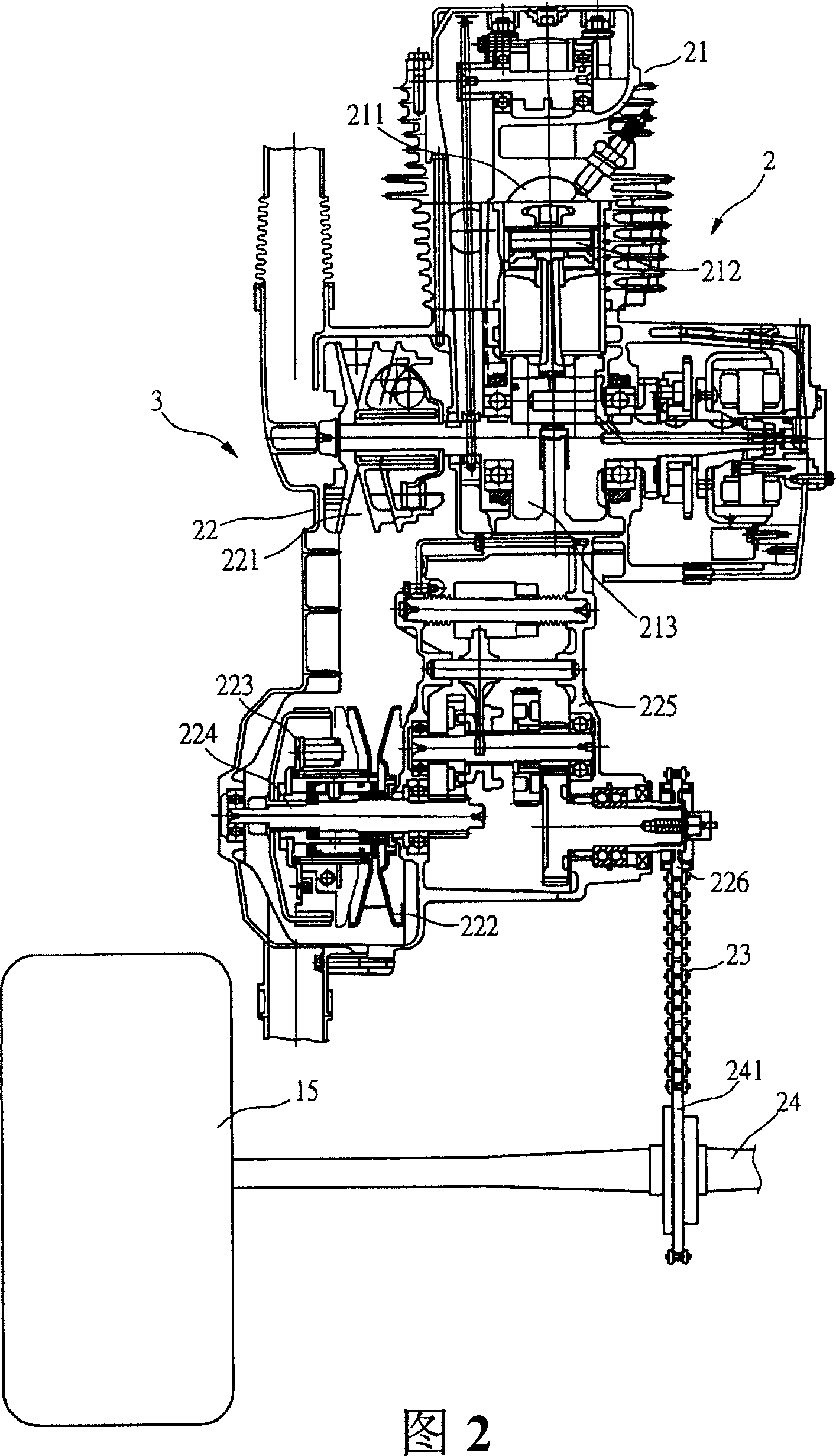

A technology for buffering devices and all-terrain vehicles, applied to chain/belt transmission devices, hoisting devices, portable lifting devices, etc., capable of solving problems such as deformation, broken chains 23, and affecting the normal driving of all-terrain vehicles 1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to be easier to understand the structure of the present invention and the effects that can be achieved, the accompanying drawings are described as follows:

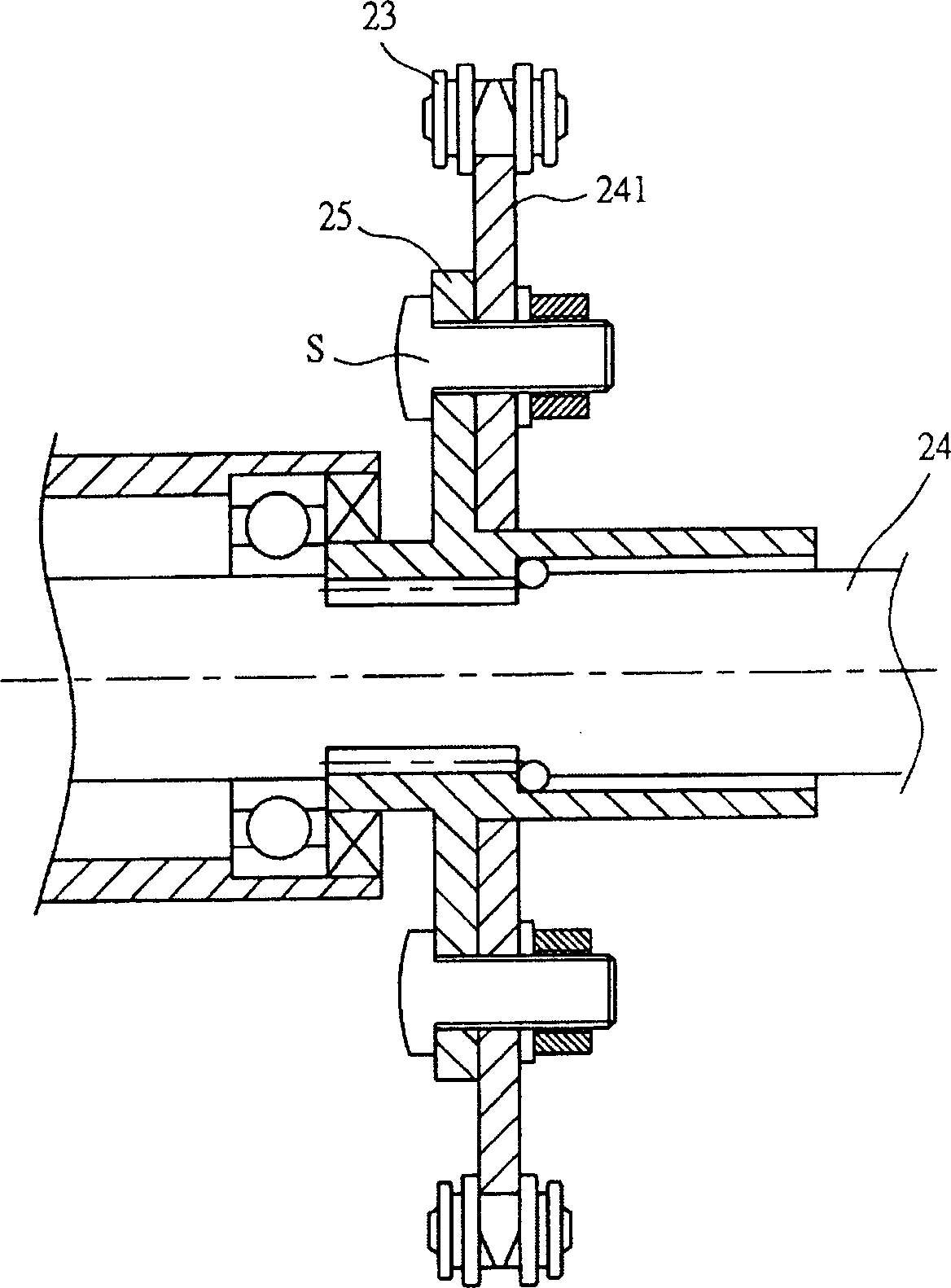

[0027] First, please refer to FIG. 4 , the buffer device for the sprocket of an all-terrain vehicle of the present invention at least has a sprocket 3 , a fixing seat 4 , several bushings 5 and several screw elements S.

[0028] The sprocket 3 has a gear part 31 for a chain (not shown here) to mesh with. A side of the sprocket 3 is provided with a plurality of accommodating parts 32 , and a through hole 33 is provided in the center of the sprocket 3 .

[0029] The fixed seat 4 is arranged on the other side of the sprocket 3, and the center of the fixed seat 4 is protruded with a shaft sleeve 41, which can be used for the rear wheel shaft A to be worn. The fixing hole 42 of the accommodating portion 32 of the sprocket 3 .

[0030] Bushing 5, the bushing 5 is an annular body, the inner and outer rings of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com