Three-coordinate measuring machine-tool error compensation system and method

A three-coordinate measurement and error compensation technology, applied in the field of error compensation system, can solve the problems of processing and assembly errors, affecting measurement accuracy, time-consuming, etc., and achieve the effects of reducing processing costs, improving measurement accuracy, and wide compensation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

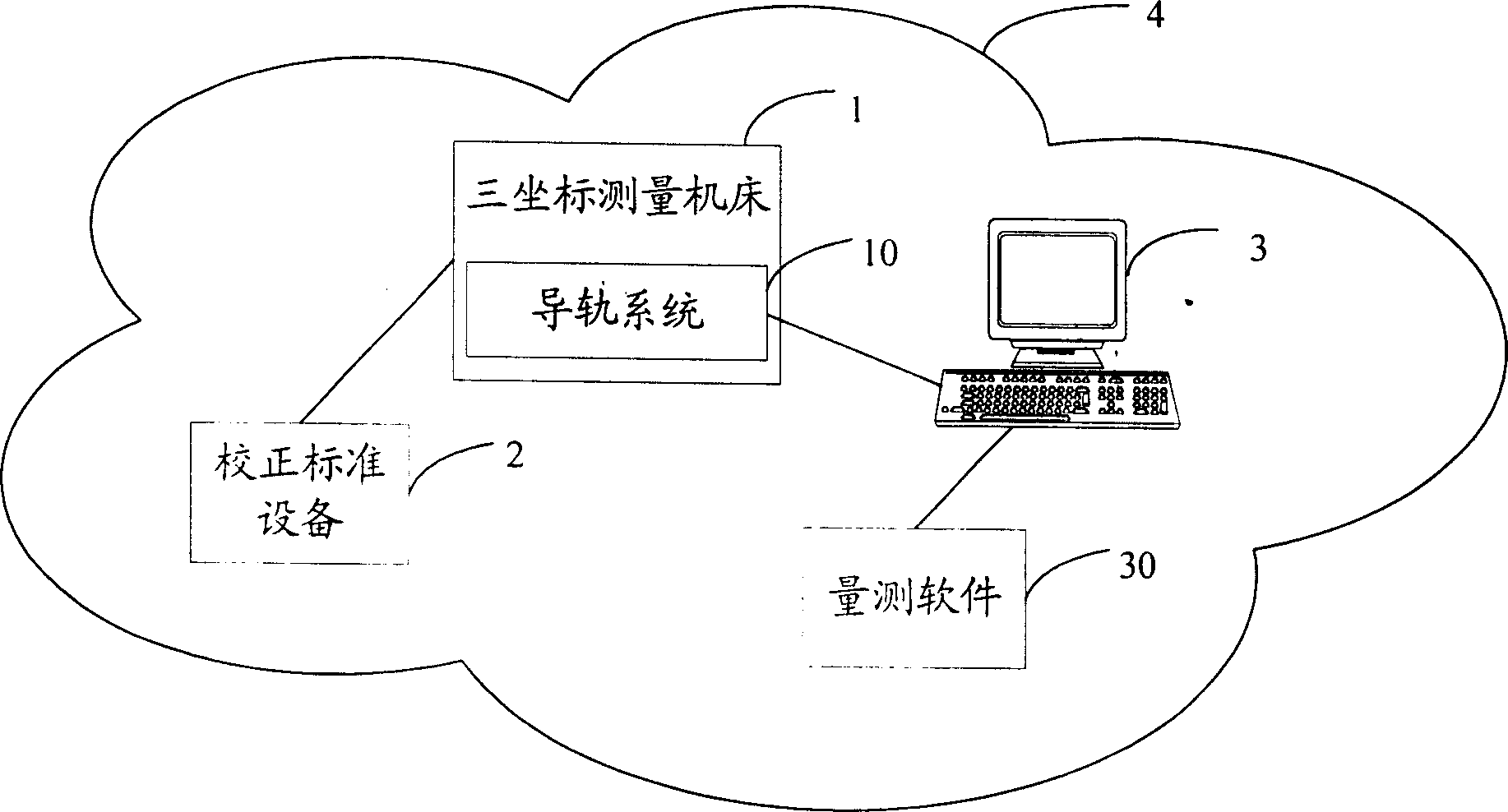

[0013] Such as figure 1 Shown is a hardware architecture diagram of a preferred embodiment of the error compensation system for a three-coordinate measuring machine tool of the present invention. The three-coordinate measuring machine tool error compensation system 4 includes a three-coordinate measuring machine tool 1 , a calibration standard device 2 and at least one client computer 3 . The three-coordinate measuring machine tool 1 includes a guide rail system 10 , which is the main cause of mechanism processing and assembly errors of the three-coordinate measuring machine tool. Calibration standard equipment 2, such as a laser interferometer, is used to detect the position error, straightness error and angular pendulum error of the three-coordinate measuring machine tool 1. The client computer 3 provides an operation interface for three-coordinate measurement machine tool error compensation, which includes the operation and operation of a measurement software 30, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com