Radiating system

A heat dissipation system and heat sink technology, applied in cooling/ventilation/heating transformation, instrumentation, electrical digital data processing, etc., can solve the problems of fan speed noise, single heat dissipation form, water-cooled heat dissipation device cannot dissipate heat from electronic circuit boards, etc. To achieve the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

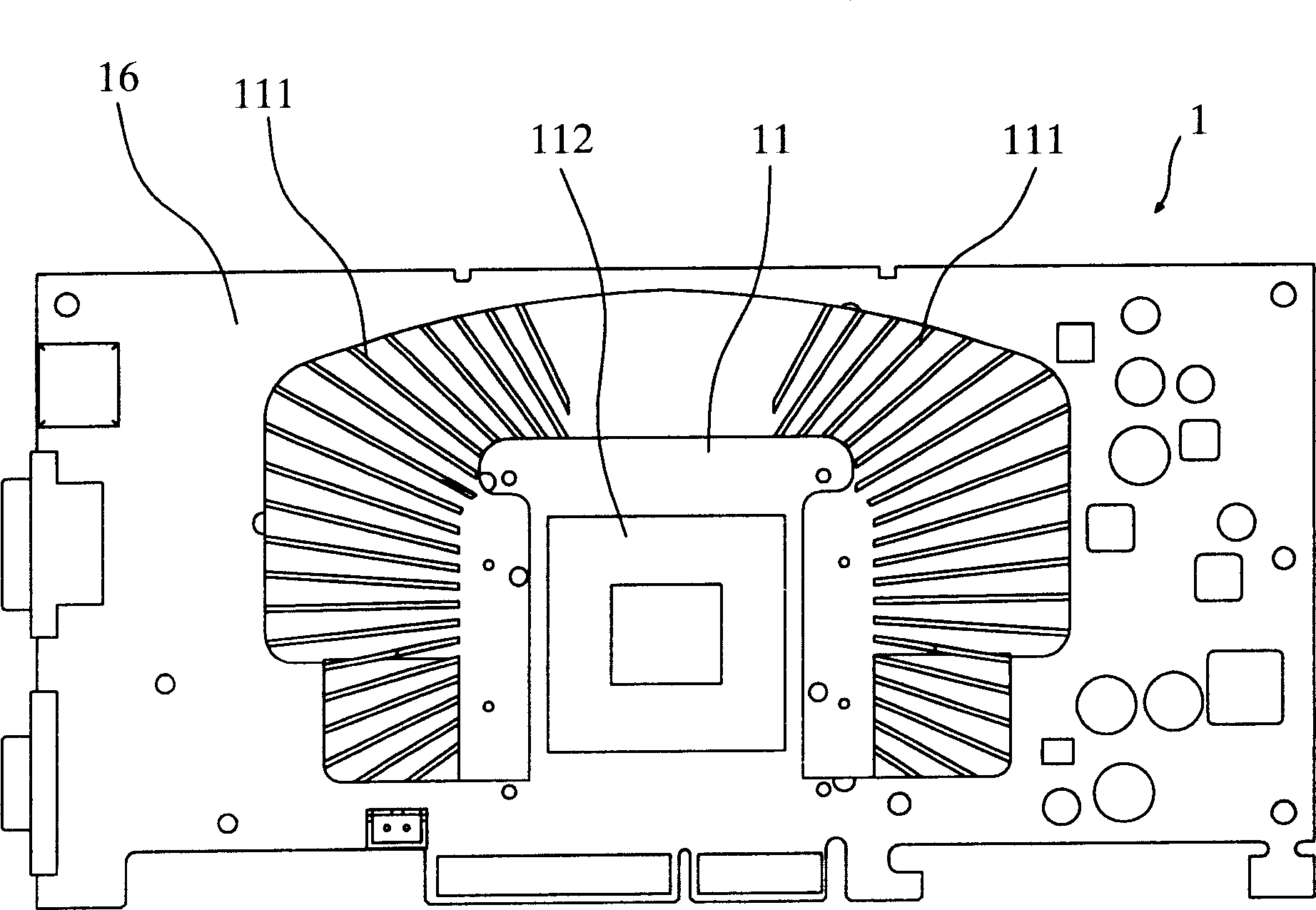

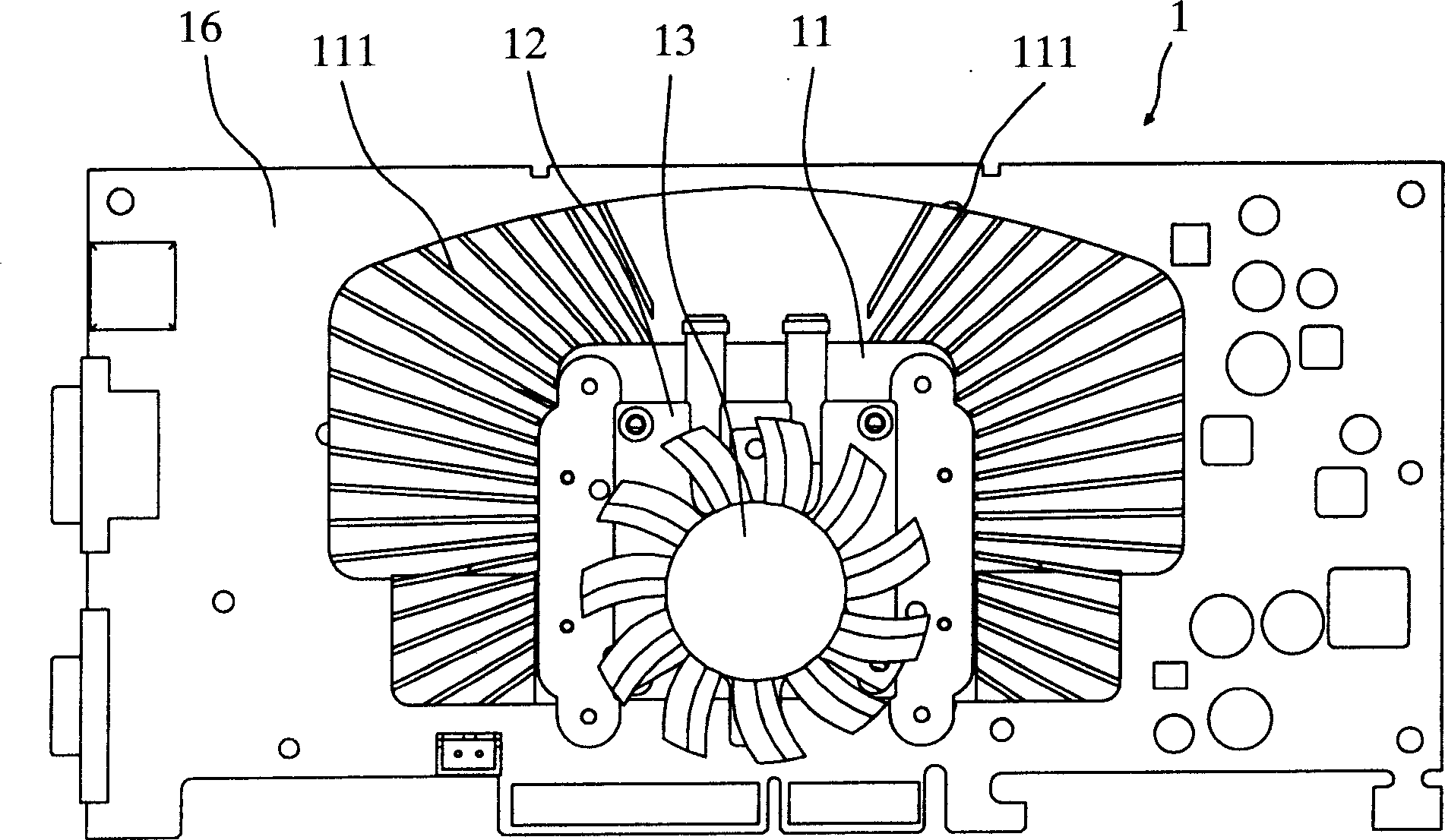

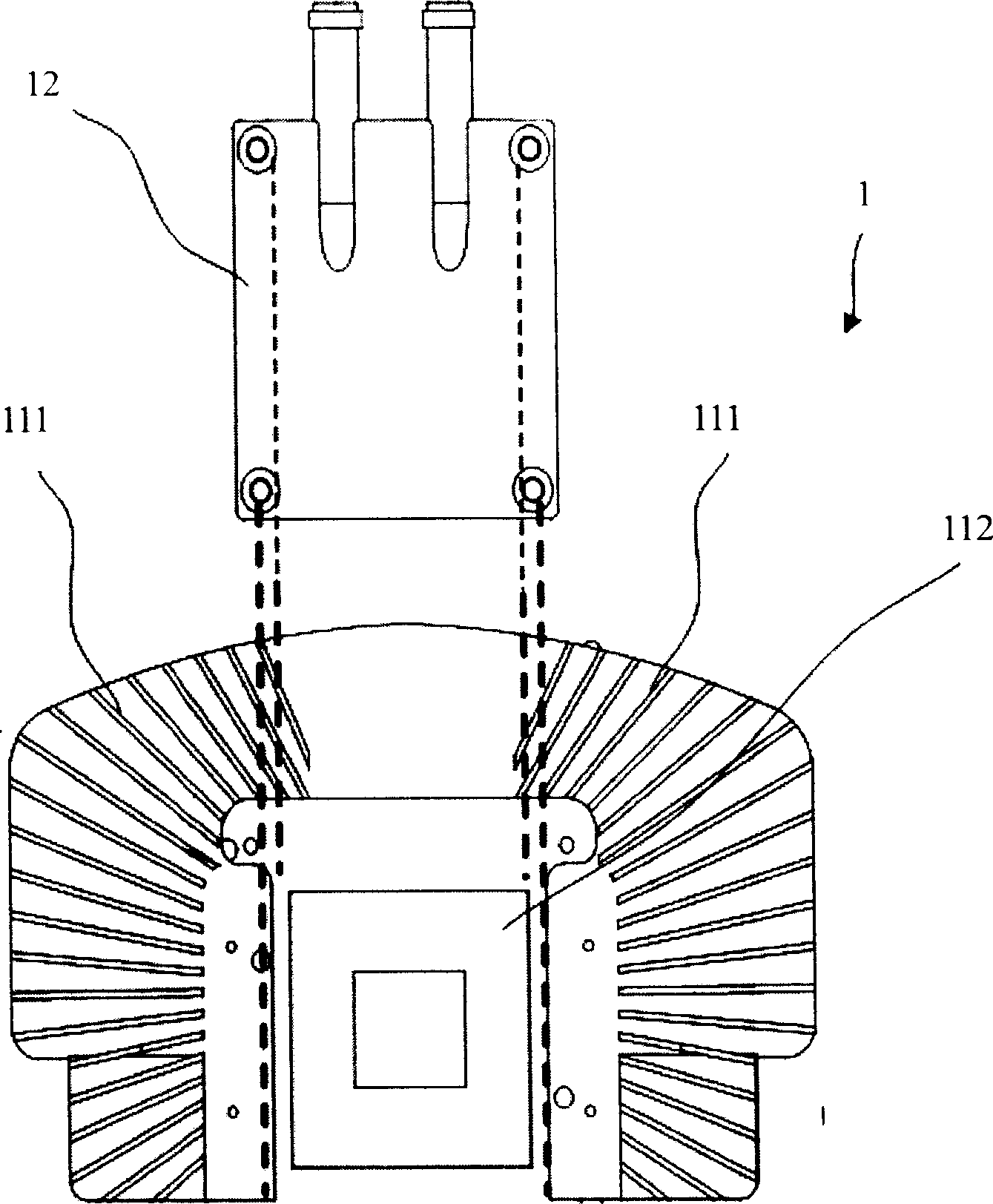

[0036] The present invention is a heat dissipating system, which is used to remove heat energy generated by an electronic component during operation. In particular, the present invention is a dual-mode heat dissipating system. The dual-mode heat dissipating system uses heat exchange, heat conduction, or a combination of both to remove the electronic components generated during operation. heat energy. A fan can also be added to the dual-mode heat dissipation system, so that the fan can provide an airflow to expedite the removal of the heat energy generated by the electronic components during the working process.

[0037] The dual-mode heat dissipation system provided by the present invention is used for heat dissipation of electronic components, such as heat dissipation of a display chip or heat dissipation of a central processing unit. Several preferred specific embodiments and implementation methods of the present invention will be described in detail below.

[0038] see F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com