A method and process for controlling the temperature, pressure-and density profiles in dense fluid processes

A fluid and pressure technology, which is applied in the control of temperature, pressure and density profiles and process fields in dense fluid processing, can solve the problems of small heat exchange area, low process efficiency, large fluctuation of product quality, etc., and achieve high capacity output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

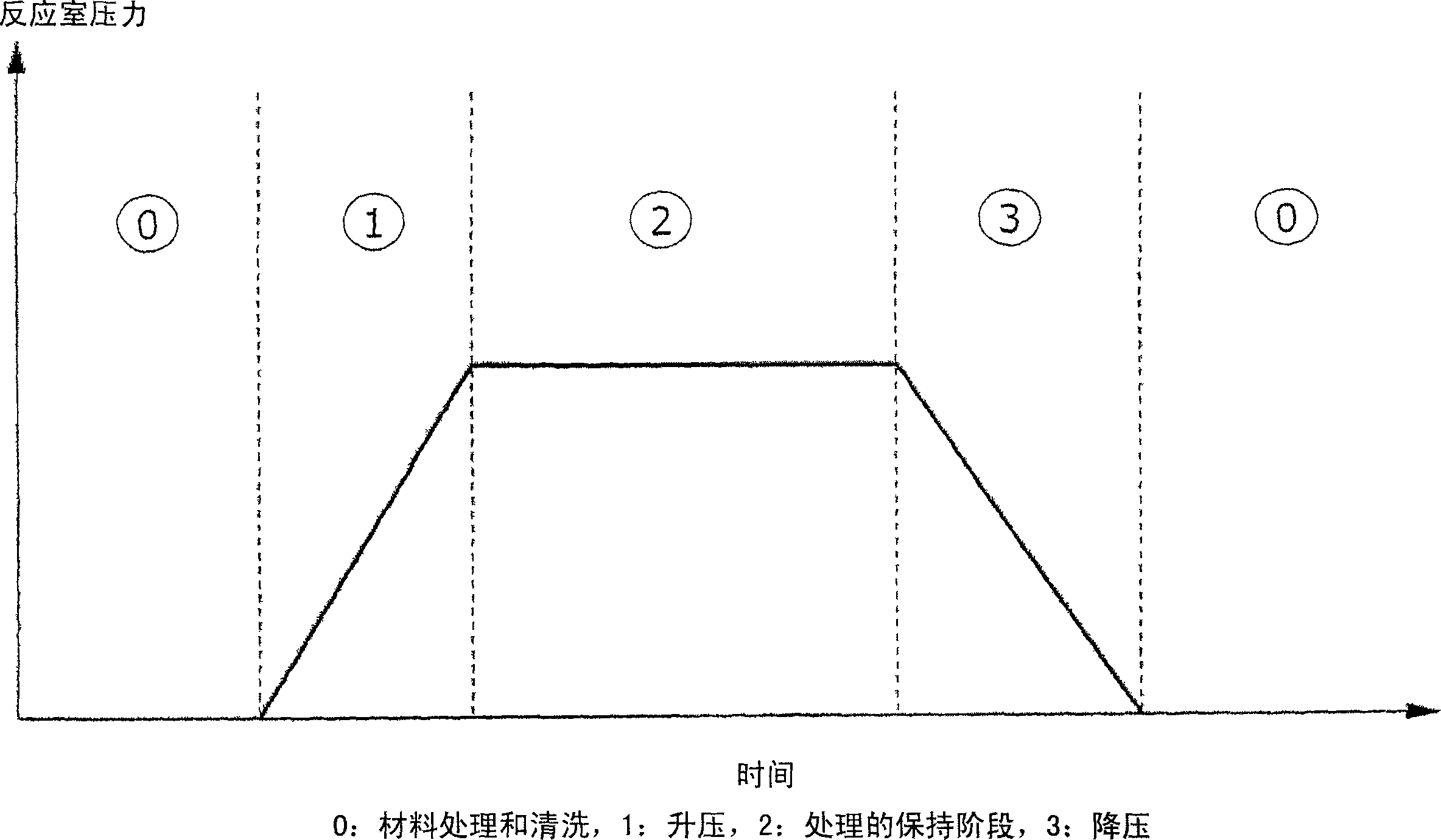

[0257] Example 1: Cyclic process for supercritical impregnation

[0258] The traditional supercritical impregnation process consists of 3 consecutive steps: The material to be treated is introduced into a pressure vessel.

[0259] In a first step, a fluid is added to the reactor to pressurize the vessel until the pressure in the vessel exceeds the desired pressure of the fluid. The temperature of the fluid can be controlled by conventional means prior to introduction into the vessel, and the temperature in the reactor is further controlled to a level exceeding the desired temperature of the fluid by controlling the wall temperature. Upon reaching the temperature and pressure, the fluid sequestered in the vessel enters a supercritical state and the impregnating compound becomes soluble in the fluid. Compression of the fluid in the container further occurs as the container is pressurized as the fluid is introduced, and as the fluid is defined to be compressible. The heat from ...

Embodiment 2

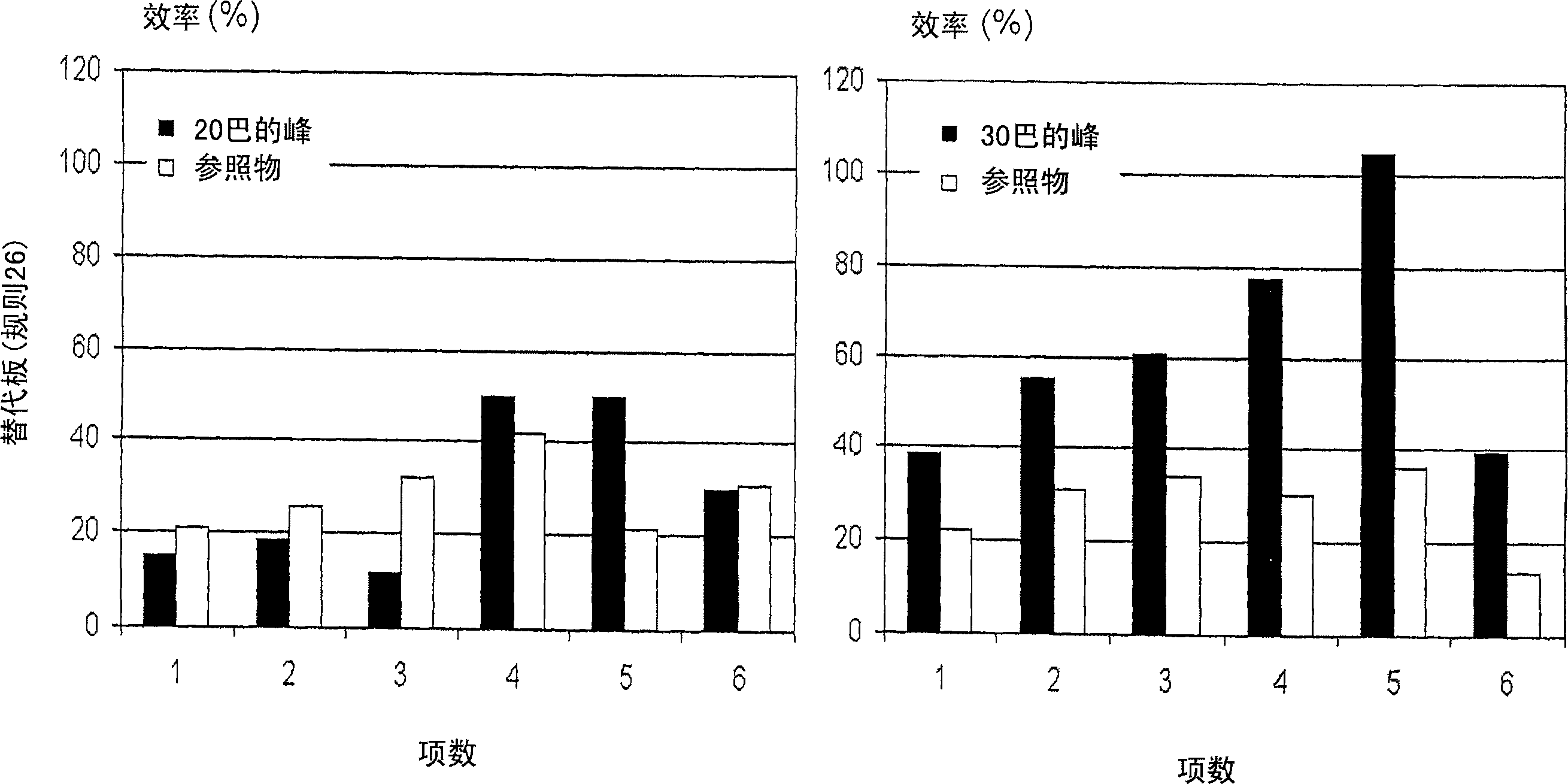

[0262] Example 2. Cyclic pulsation process for supercritical impregnation

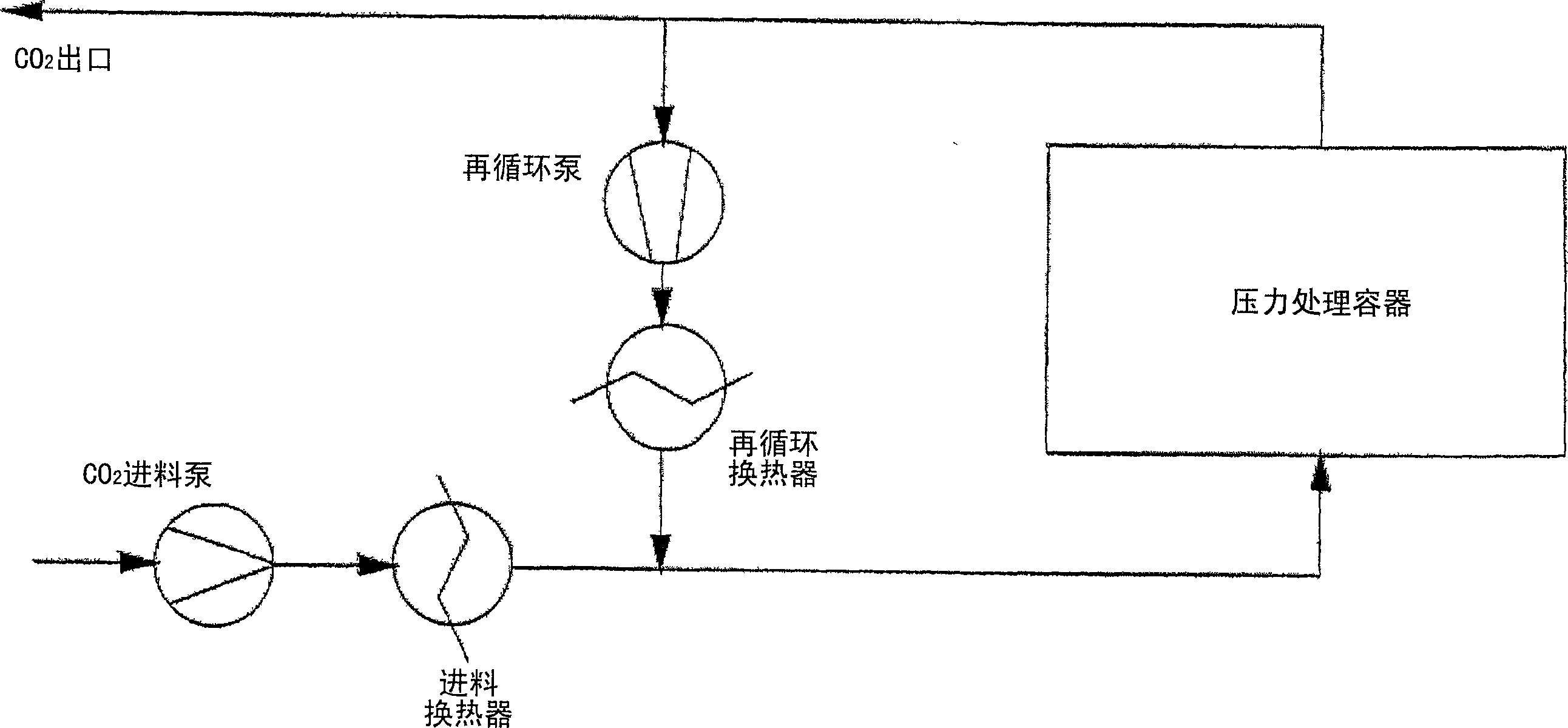

[0263] During the holding phase of the supercritical impregnation phase, as described in Example 1, the pressure and temperature were maintained substantially constant. The dispersion of the impregnating compound in the impregnated porous material is therefore mainly due to diffusion, since there is no convective supercritical solvent flow inside the porous material. To enhance and speed up the dispersion of the impregnating compound, pressure pulsations can be introduced during the impregnation stage, creating convection within the material. In order to preserve the dissolved impregnating compound in the vessel, pressure pulsations are preferably introduced by pulsations of the supercritical solvent inlet temperature, that is, by changing the set point of the heat exchanger in recirculation mode in the recirculation loop. By pulsating the pressure, a pumping effect is created in the porous material, ...

Embodiment 3

[0269] Example 3 Cyclic Supercritical Process with Recycle

[0270] One aspect of the present invention relates to a cyclic process for supercritical extraction processing of materials.

[0271] Thus, in a preferred embodiment of the present invention, the material treated using the supercritical extraction process is initially loaded into a pressure vessel.

[0272] In many applications, the recycle process begins by cleaning the vessel with the specific fluid used in the recycle process to minimize contamination of the fluid. This cleaning can be carried out by applying a vacuum (pressure below ambient pressure) into the vessel while feeding a specific fluid into the vessel for a certain period of time. Typically, the cleaning time is between 1 and 20 minutes. In other cases, the cleaning can be carried out by pressurizing the vessel up to 0.5-5 bar above ambient pressure, and emptying the vessel until the pressure is substantially the same as ambient pressure. Any combin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com