Bracket fixing structure of motor

A technology for fixing structures and brackets, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of screw corrosion, etc., and achieve a solid bonding state, easy assembly and disassembly process, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the drawings and embodiments.

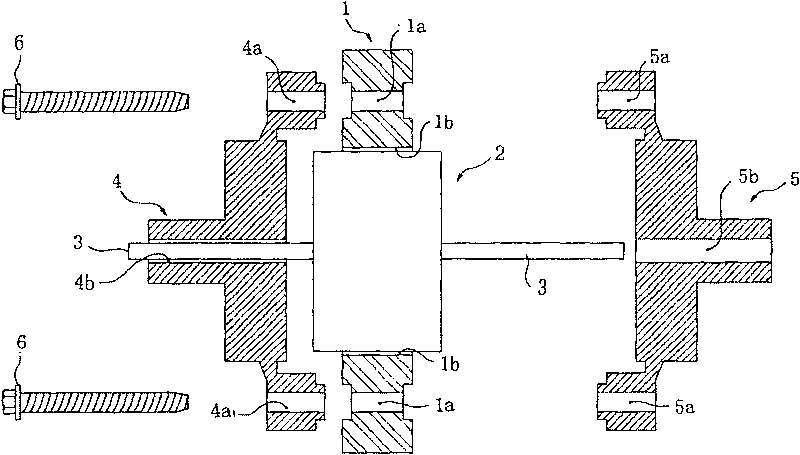

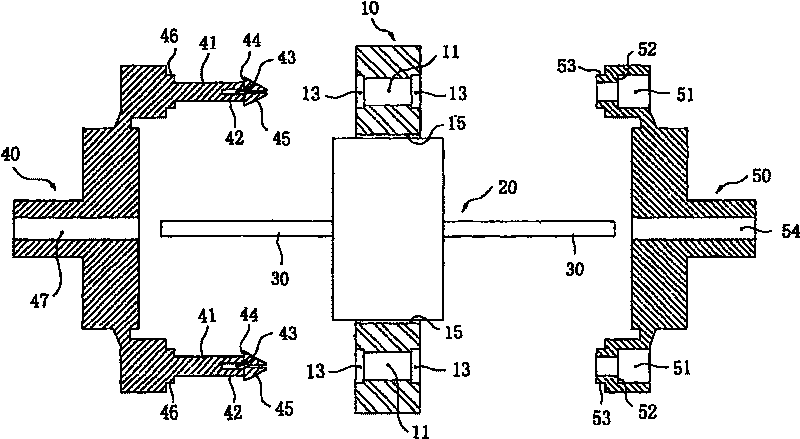

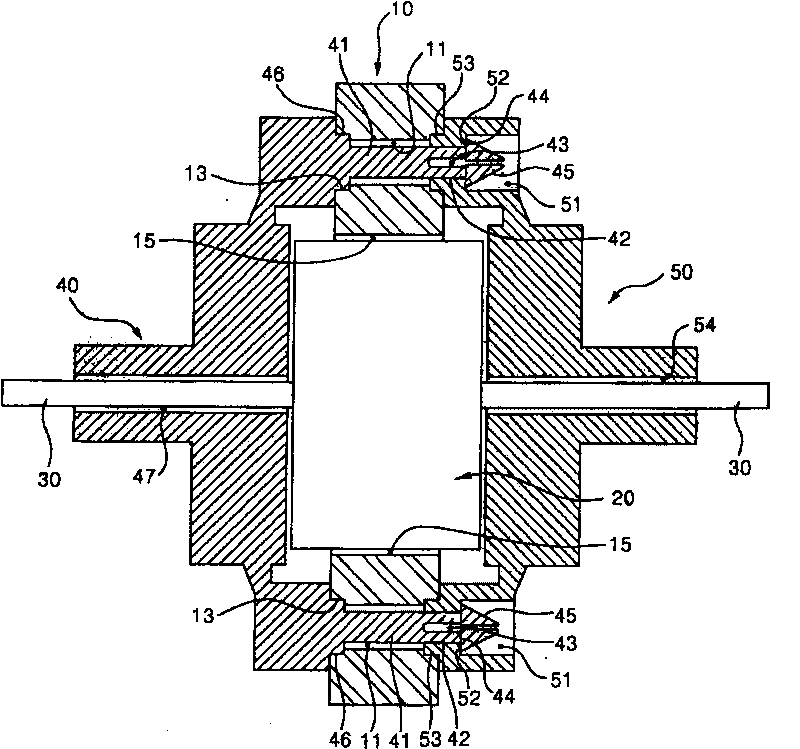

[0027] figure 2 Is an exploded sectional view of the fixing structure of the motor bracket of the present invention, image 3 It is an assembly sectional view of the fixing structure of the motor bracket of the present invention. As shown in the figure, a pair of through holes 11 are formed in the stator 10 of the motor. The through holes 11 are portions where the fixing rods 41 each having both sides of the first bracket 40 will penetrate. Both ends of the through hole 11 are formed with mounting grooves 13 having a relatively larger diameter than the through hole.

[0028] In addition, a rotor hole 15 for inserting the rotor 20 is formed in the stator 10. The rotor 20 rotates with the rotating shaft 30 as the center under the electromagnetic force interaction with the stator 10.

[0029] There are also first and second brackets 40 and 50 for rotatably supporting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com