Single layer well wall with connecting plate and its constructing method

A technology for connecting stubble boards and shaft walls, which is applied in shaft equipment, earthwork drilling, shaft lining, etc., can solve problems such as unreasonable double-layer composite shaft wall structure, increased cost of shaft freezing engineering, and increased construction cost of shaft excavation, etc. Achieve the effects of wide practicability, simple structure and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

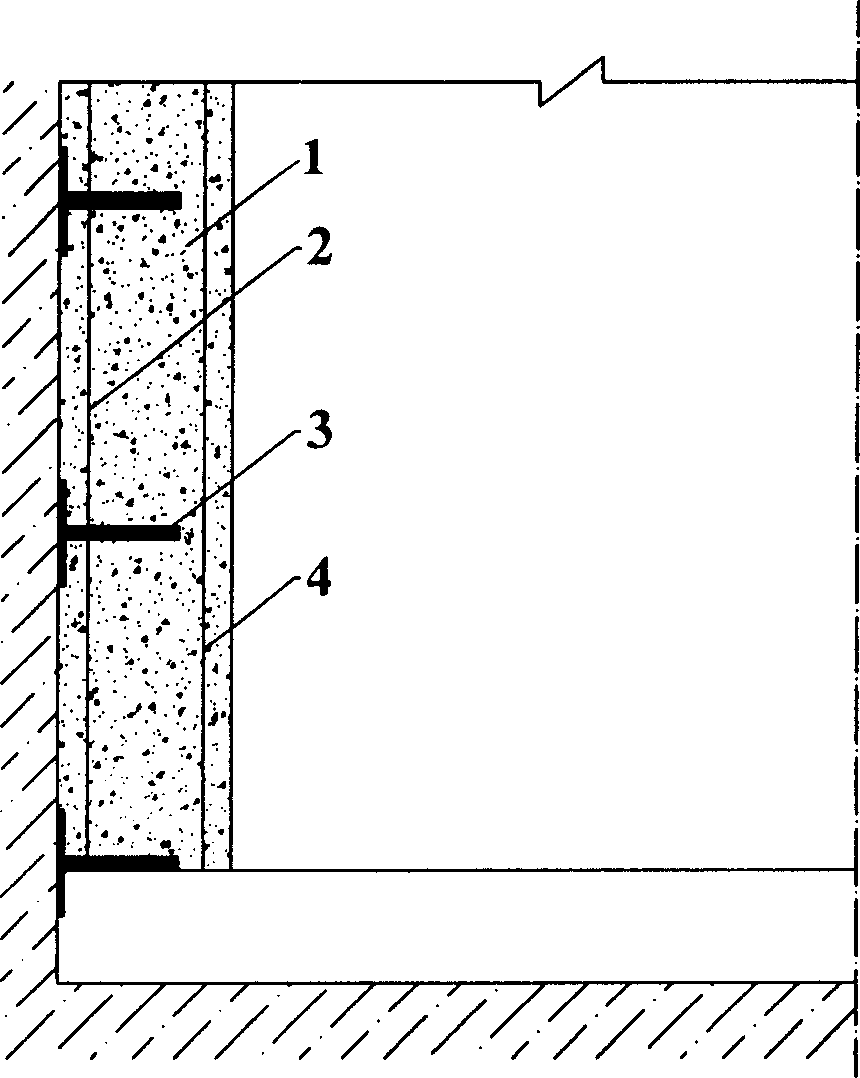

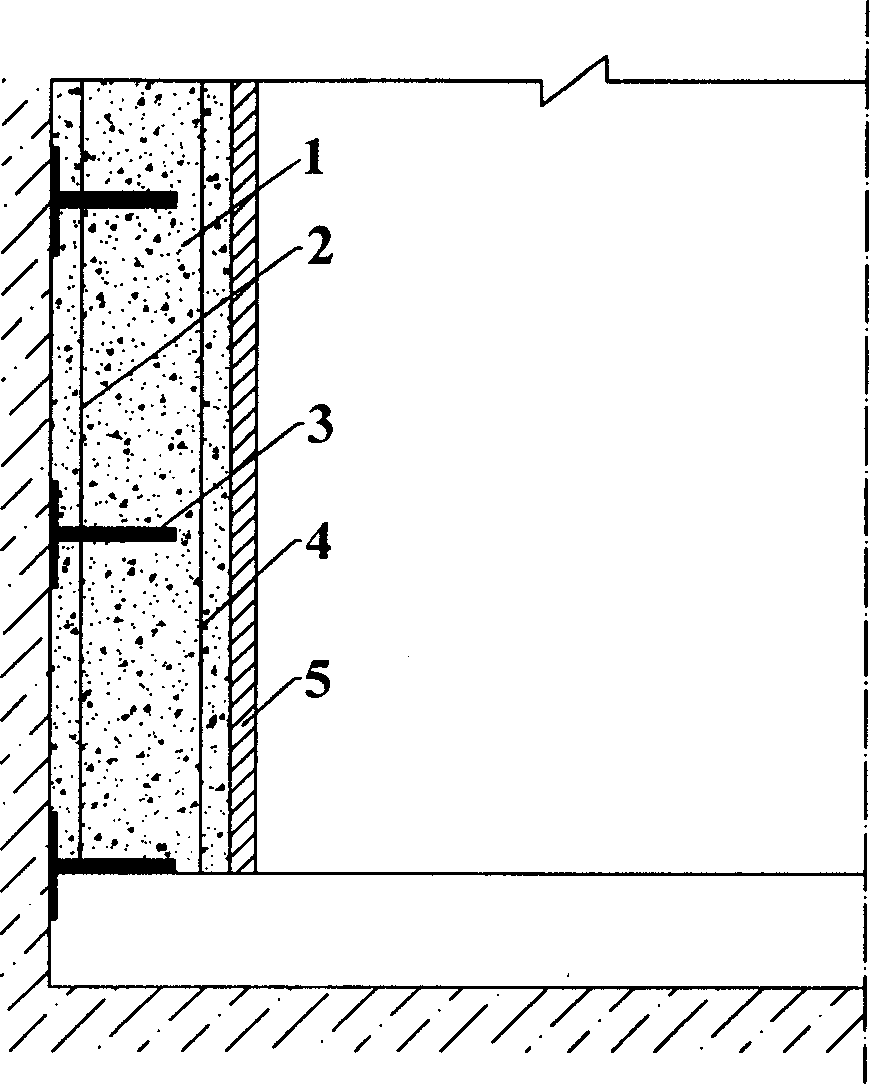

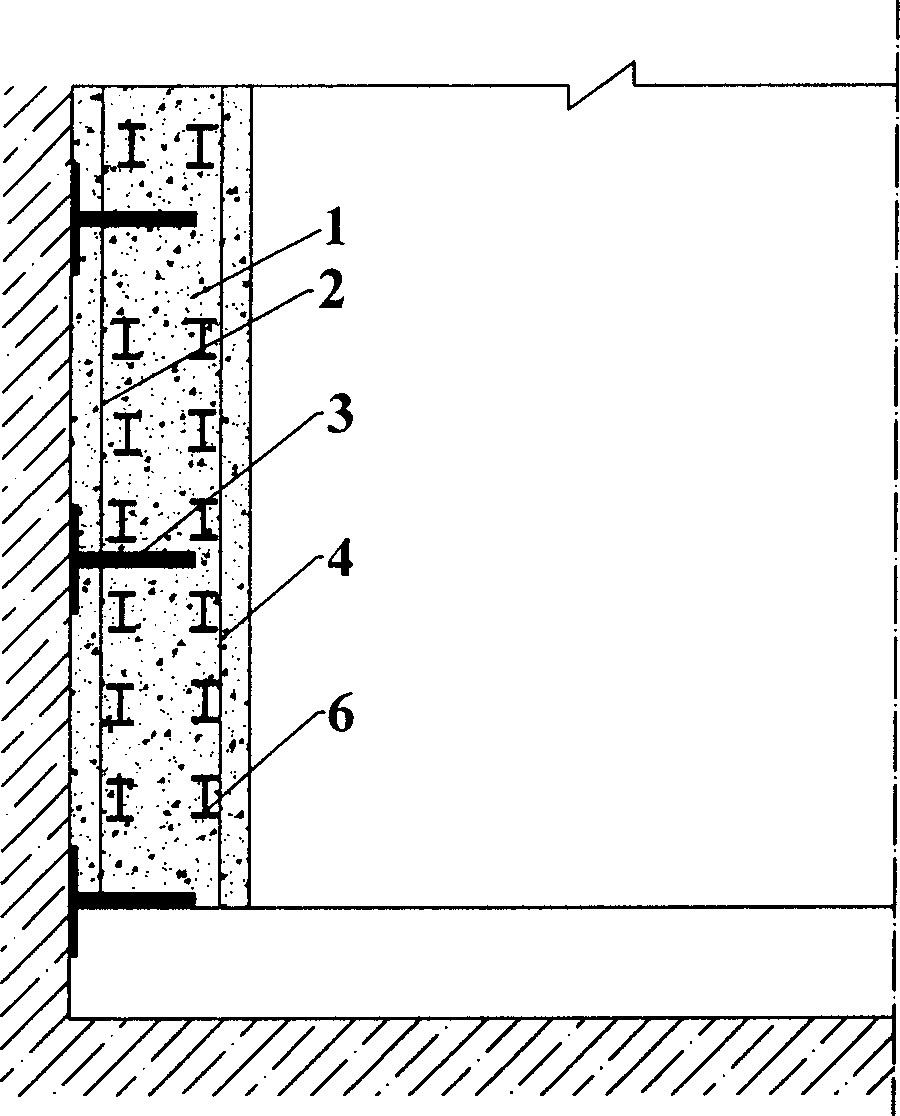

[0020] The single-layer shaft wall with the stubble plate of the present invention, figure 1 As shown, it is mainly composed of concrete 1, connecting rod 2, stubble board 3, and steel bar 4. According to the design requirements, a steel skeleton 6 can be added in the well wall. image 3 shown; or add a steel plate 5 inside the well wall, figure 2 shown; or add a ribbed arc-shaped plate 7 inside the well wall, Figure 4 shown. The cross section of stubble board 3 can be shape, can also be Shaped or corrugated, the stubble board 3 is arranged at the stubble place of the single-layer shaft wall section 1, and the stubble board 3 mainly plays the role of stubble water stop. At the place where the stubble is connected to the upper and lower shaft walls, the stubble board 3 is used to partially or completely change the direct contact of the new and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com