Multiple air-intaking channel and supersonic speed whirl-flow separator and its back pressure device

A swirl separation, supersonic technology, applied in swirl devices, devices whose axial direction of swirl remains unchanged, separation methods, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

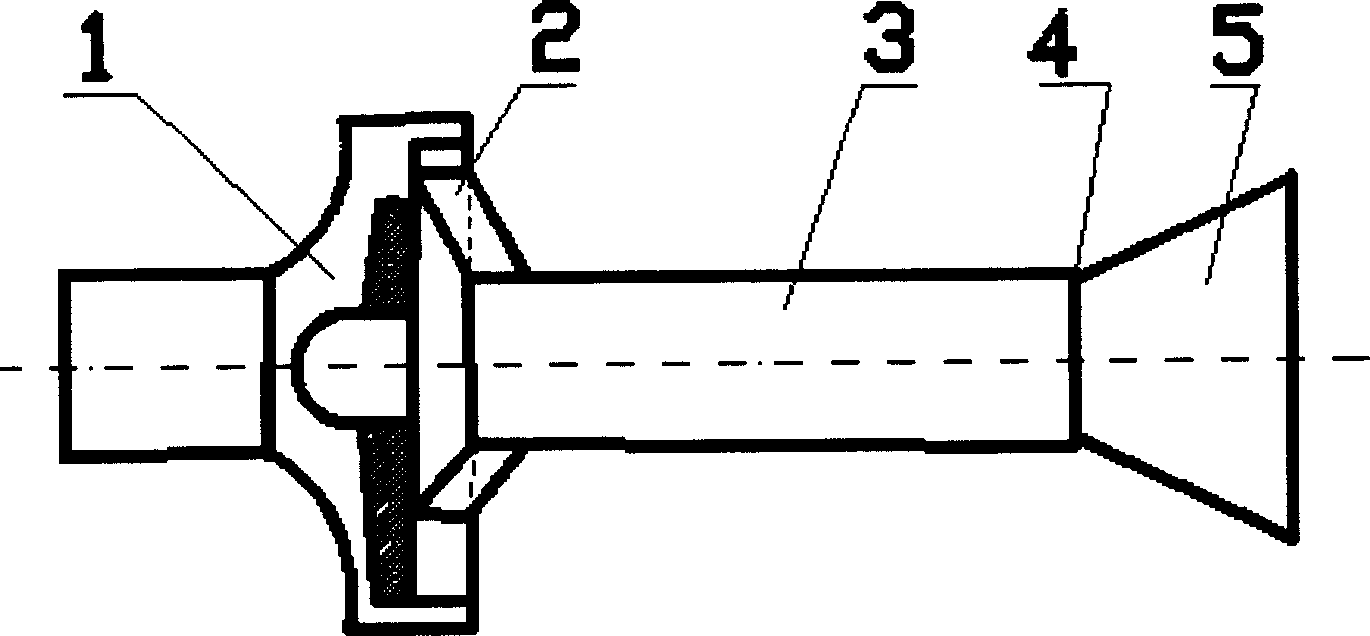

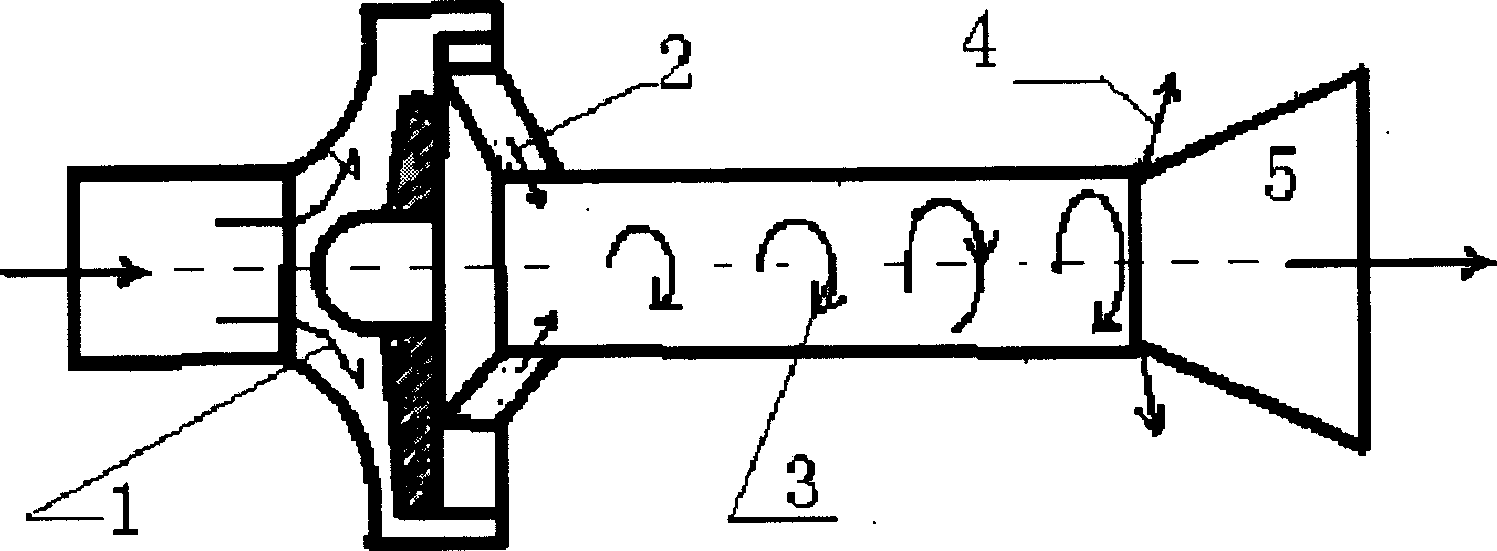

[0014] see figure 1 , the present invention comprises diversion chamber 1 and the nozzle pipe 2 that communicates with diversion chamber 1 and cyclone separation section 3, the outlet of cyclone separation section 3 is communicated with back pressure device 5, and the outlet between cyclone separation section 3 and return A liquid discharge port 4 is also arranged between the compressors 5, because the device works in a high-pressure and corrosive environment, so the material of the device is required to be resistant to high pressure, corrosion and erosion.

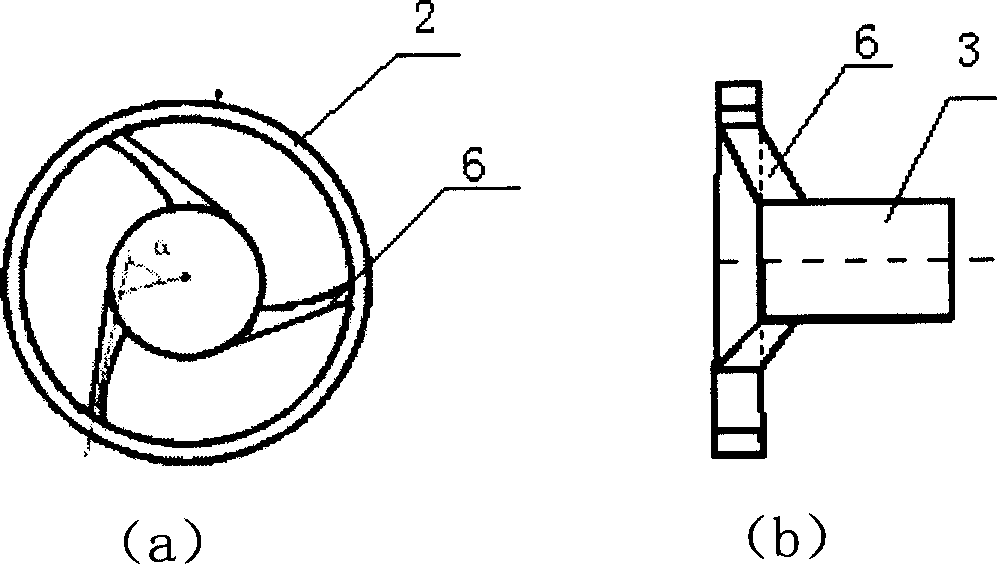

[0015] see figure 2 , the working principle of the present invention is as follows: the moisture is rectified in the diversion cavity 1 and the flow direction is changed to ensure that the high-pressure airflow enters the nozzle 2 along the circumferenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com