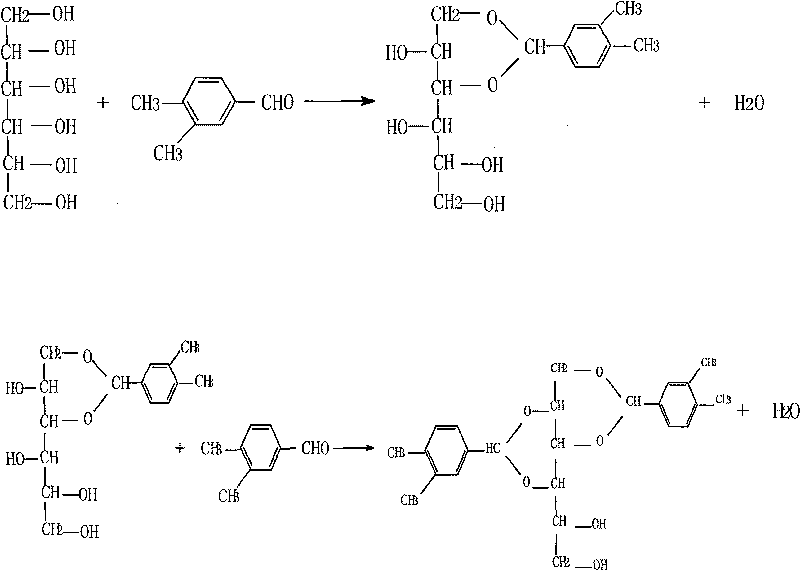

Method of synthesizing high purity 1,3:2,4-di (3,4-dimethyl) benzyl cross sorbic alcohol

A technology of benzylidene sorbitol and dimethyl, which is applied in the field of high purity 1, can solve the problems of coke cleaning trouble, large equipment investment, complex equipment structure, etc., and achieves the effect of simple operation, simple equipment structure and improved reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In a 1L reactor equipped with a condenser and an oil-water separator paddle stirrer, add 18 g of 98% sorbitol, 1.5 g of p-toluenesulfonic acid, 3.0 g of tetrabutylammonium bromide, and cyclohexyl Alkane 315ml, then start the stirrer, and add 29g of 95% 3,4-dimethylbenzaldehyde, and heat to a temperature of 80°C, at which point the cyclohexane refluxes and starts to react. The water generated by the reaction is distilled out together with the cyclohexane, condensed by the condenser, separated by the oil-water separator, the solvent cyclohexane is refluxed into the reaction kettle, and the stirring speed is controlled at about 80 rpm. After reacting for 1 hour, when the reaction system gradually becomes viscous, increase the stirring speed to 100-130 rpm. Then slowly add reaction accelerator methanol solution 160ml at a time, after that, the temperature of the reaction system will gradually decrease, and the viscous state of the material will be alleviated. Keep the refl...

Embodiment 2

[0022] In the 1L reaction kettle that condenser, oil-water separator paddle type stirrer are housed, add content successively and be sorbitol 18g of 98%, p-toluenesulfonic acid 1.5g, tetrabutylammonium chloride 3.0g, 315ml of cyclohexane, then start the stirrer, and add 29g of 3,4-dimethylbenzaldehyde whose content is 95%, and heat to a temperature of 80°C, at which time the cyclohexane reflux starts to react. After reacting for 1h, add reaction accelerator methanol solution 60ml in reactor, reaction system temperature reduces gradually, and material viscous state alleviates, and then every two hours adds methanol solution identical with the first addition in still, keeps like this Reflux state reaction 5.5h, the condensation reaction is over. Then add NaHCO to the reactor 3 3.5g, after the pH of the reaction system was made to be 9, the temperature was raised and the cyclohexane was evaporated for recycling. The crude DMDBS obtained was washed, filtered, dried and pulverized...

Embodiment 3

[0024] In a 1L reaction kettle equipped with a condenser and an oil-water separator paddle stirrer, add 18 g of sorbitol with a content of 98%, 1.5 g of p-toluenesulfonic acid, trimethylhexadecyl chloride Ammonium 3.0g, toluene 325ml, then start the agitator, and add 29g of 3,4-dimethylbenzaldehyde with a content of 95%, and heat to a temperature of 110°C. At this time, the toluene reflux starts to react. After 1 hour of reaction, once Add 180ml of reaction accelerator methanol solution in the reactor, the temperature of the reaction system decreases gradually, and the viscous state of the material is relieved, then every two hours, add the same methanol solution with the first addition in the kettle, so that the reflux state is maintained for 5.5 h, the condensation reaction is over. Then add NaHCO to the reactor 3 3.5g, after the pH of the reaction system was 8, the toluene was evaporated by heating up for recycling, and the crude DMDBS obtained was washed, filtered, dried, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com