Semiconductor device and manufacturing method of the same

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as poor reliability, achieve high yield, improve reliability, and easy processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

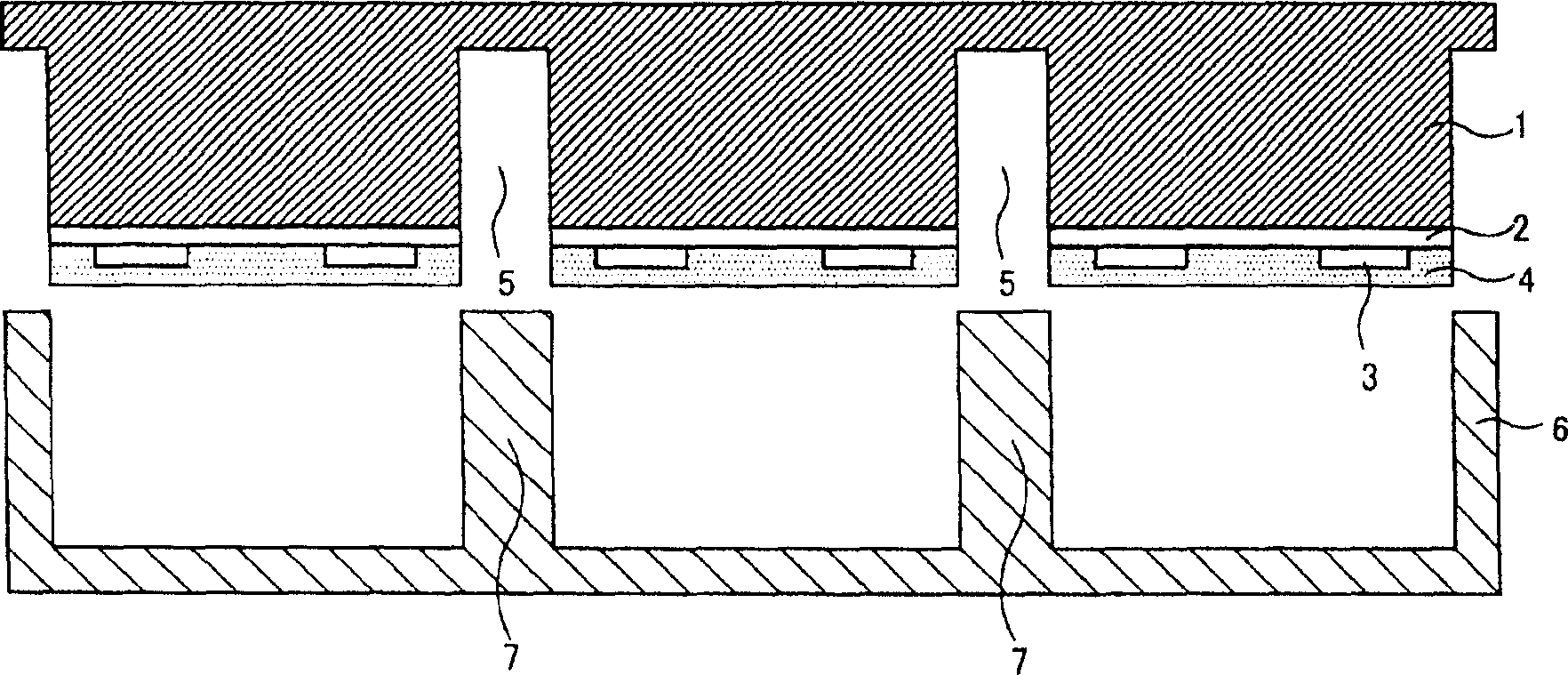

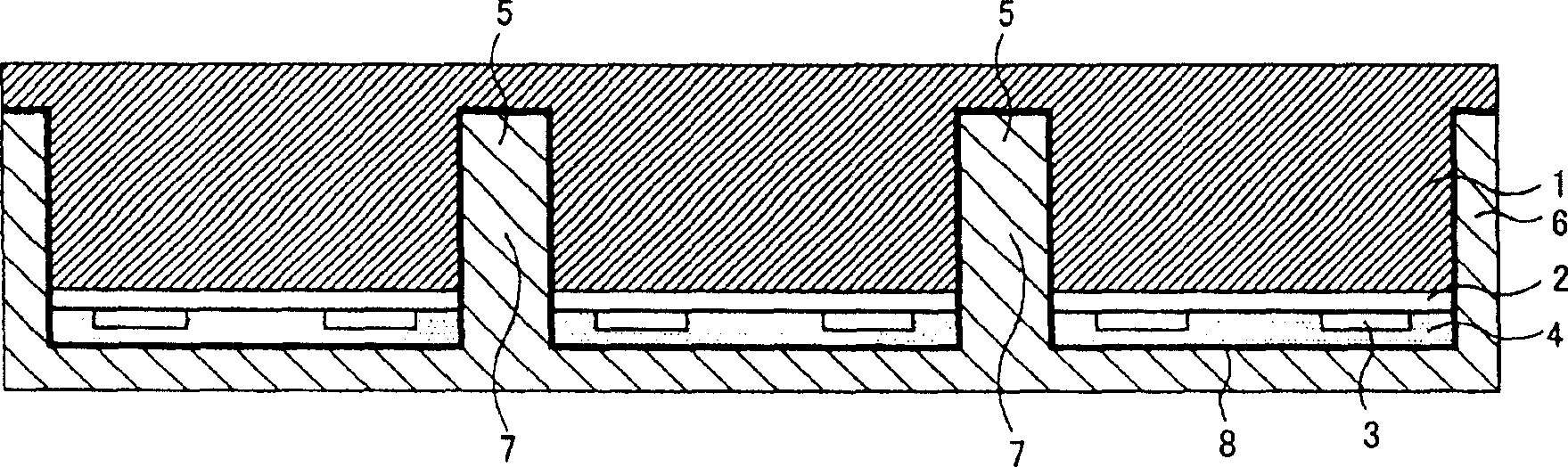

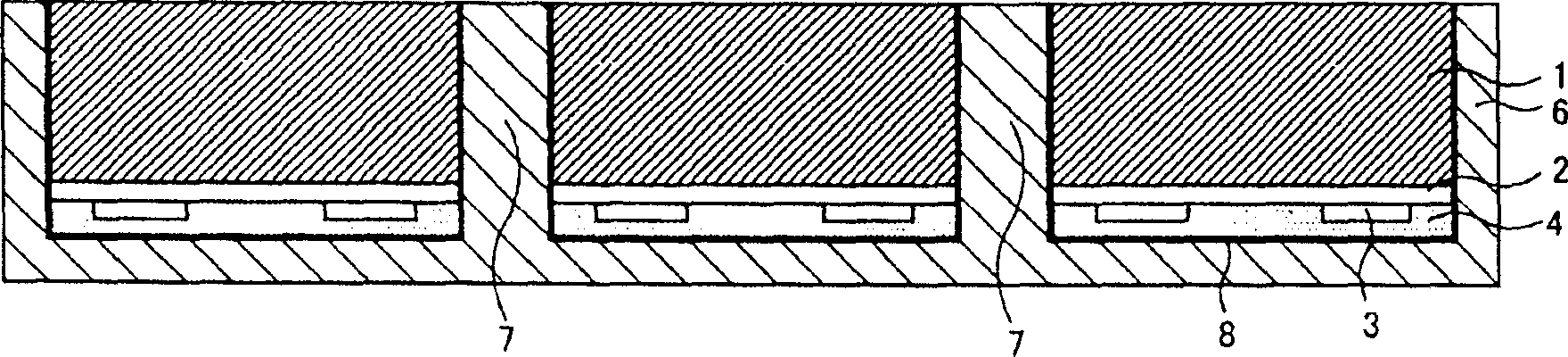

[0039] Embodiments of the present invention will be described in detail below with reference to the drawings. Figure 1 to Figure 8 Each is a cross-sectional view shown in the order of the manufacturing process. in addition, Figure 9It is a plan view of the semiconductor device of the present invention viewed from the back direction, Figure 8 is along Figure 9 The cross-sectional view of the X-X line. In addition, MOS transistors are appropriately formed on the semiconductor substrate, elements such as a plurality of wirings and plugs connecting the wirings, and elements made of a silicon oxide film are separated, but these are not shown in the figure. In addition, since the following processes are performed in the wafer process, a plurality of semiconductor devices 20 are formed at the same time, but for convenience, a process in which three semiconductor devices are formed will be described.

[0040] First, if figure 1 As shown, a first insulating film 2 (eg, a sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com