Apparatus and method of continuous gasifying preparing carbonic oxide from pure oxygen coke

A technology of carbon monoxide and coke, which is applied in the manufacture of combustible gas, petroleum industry, joint combustion mitigation, etc., can solve the problems of low efficiency, high production energy consumption, huge equipment, etc., and achieve the effect of reducing energy consumption and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

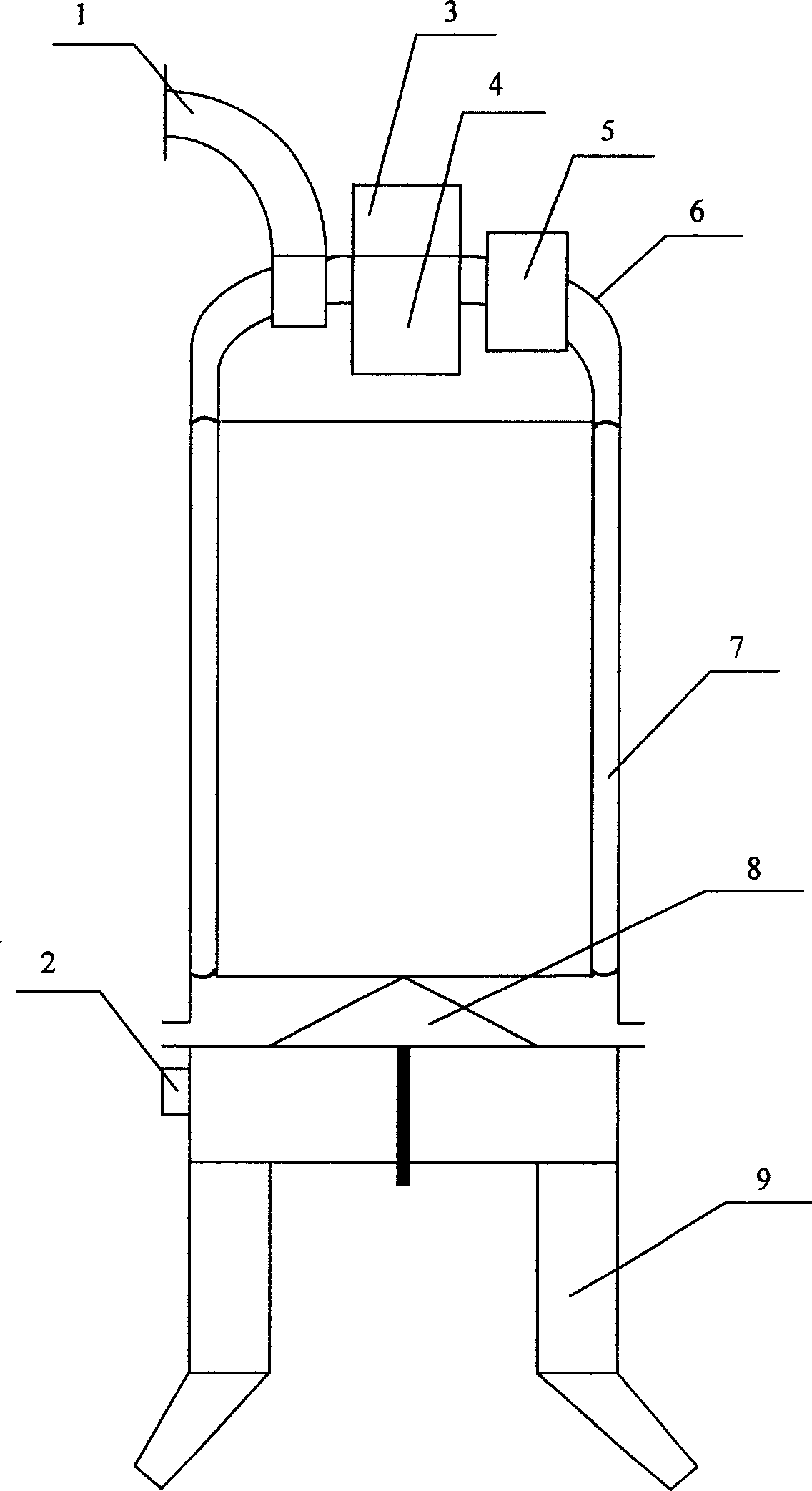

[0024] According to the accompanying drawings, the fixed bed gasifier is equipped with a water jacket 7 with a height of 2.6m ~ 5.2m and a pressure of 0.2MPa ~ 1.6MPa that can by-produce steam. Coke is fed into the furnace through an automatic coking machine and a coke distributor 4 . The automatic coke adding machine selects commercially available products with bi-focus valves or triple-focus valves. The horizontal distance between the lower end of the coke distributor 4 in the furnace at the bottom of the automatic coking machine and the upper head of the water jacket of the gas furnace is 200 mm to 600 mm to ensure that the reaction of pure oxygen coke to carbon monoxide is reliably carried out. The top of the fixed-bed gas generator adopts an elliptical head 6, and the coke inlet 3 is located at the center of the top of the head 6; an inspection port 5 is set on the concentric circle line of the gas outlet pipe 1; in order to ensure safe operation, the furnace top is ellip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com