Reciprocating pump device

A technology for reciprocating pumps and input shafts, which is applied to variable displacement pump components, components of pumping devices for elastic fluids, pump components, etc. It can solve the problems of large bending stress of the crankshaft and long distance between crankshaft bearings, etc., and achieve Reduced bending stress, improved reliability, and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Next, preferred embodiments of the reciprocating pump device of the present invention will be described in detail.

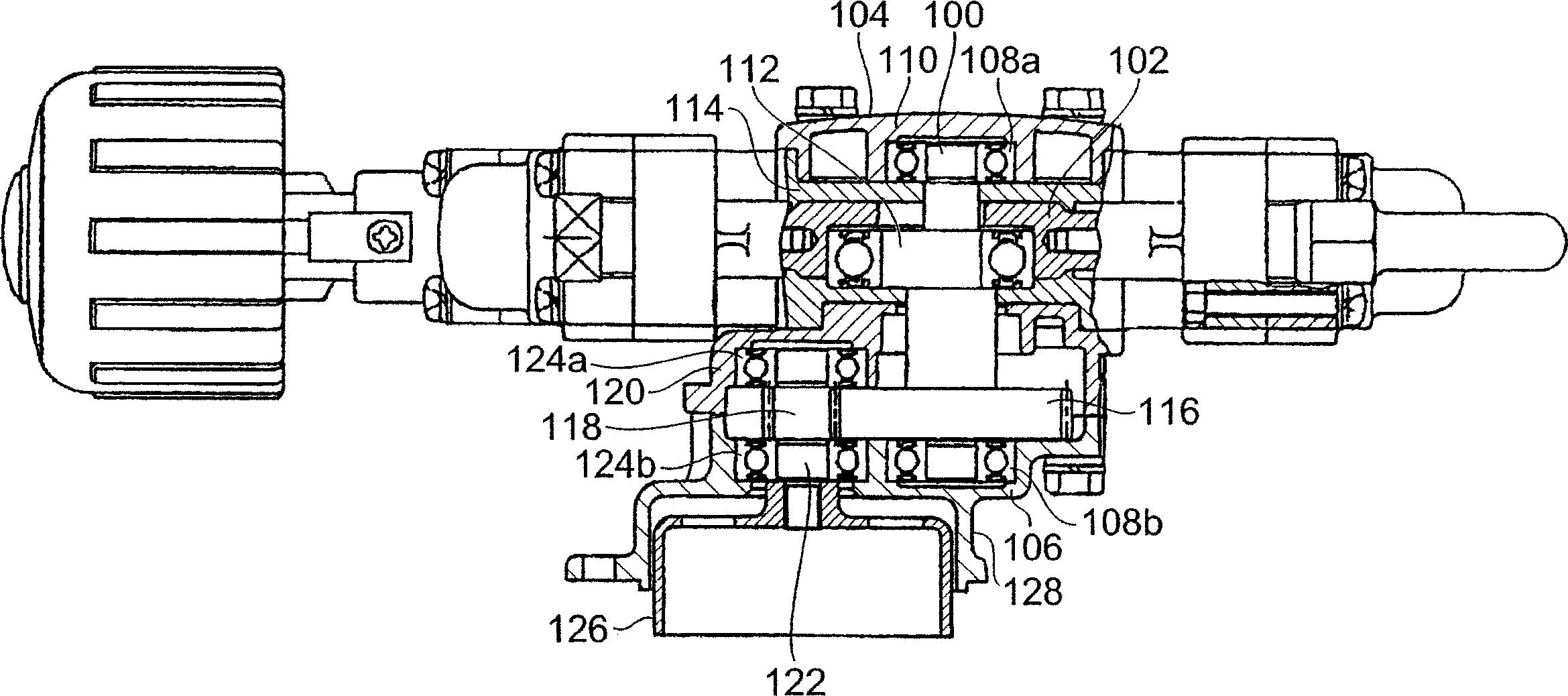

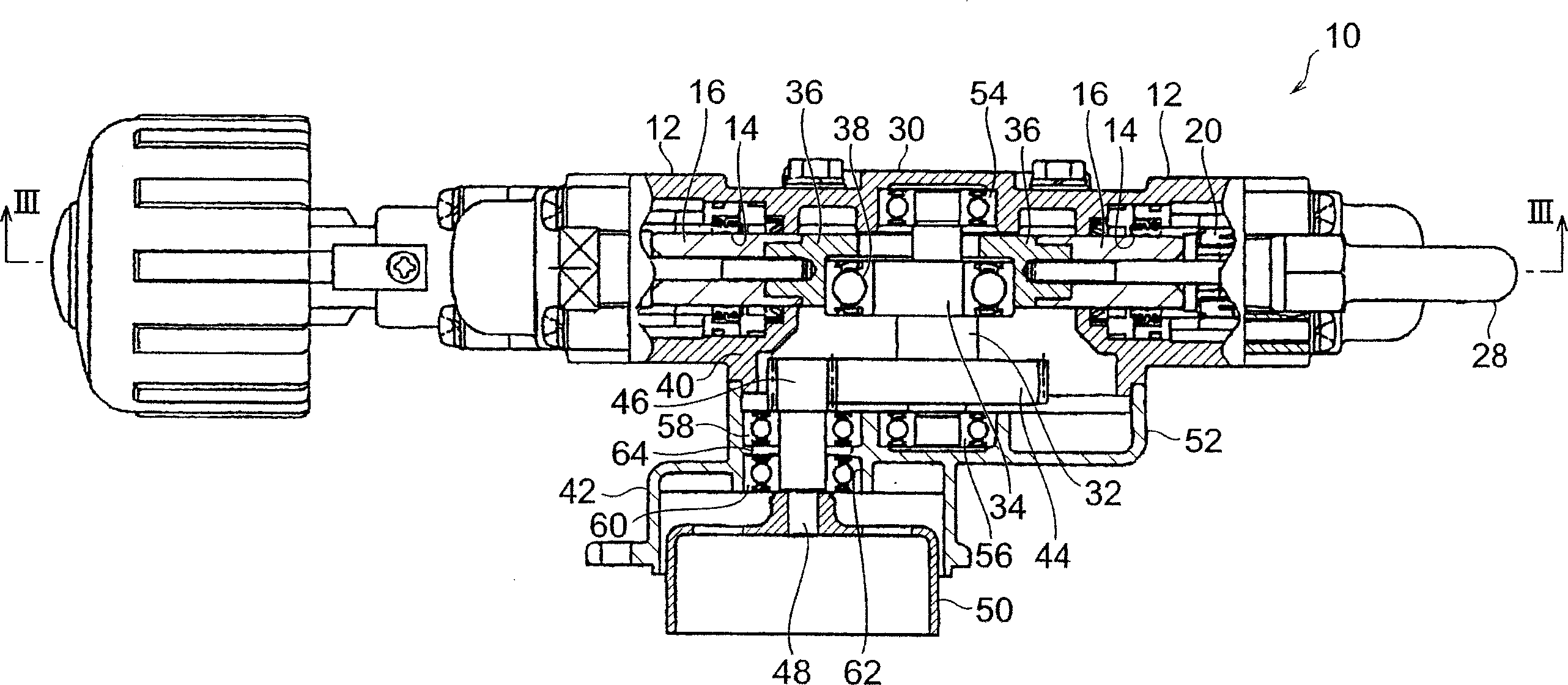

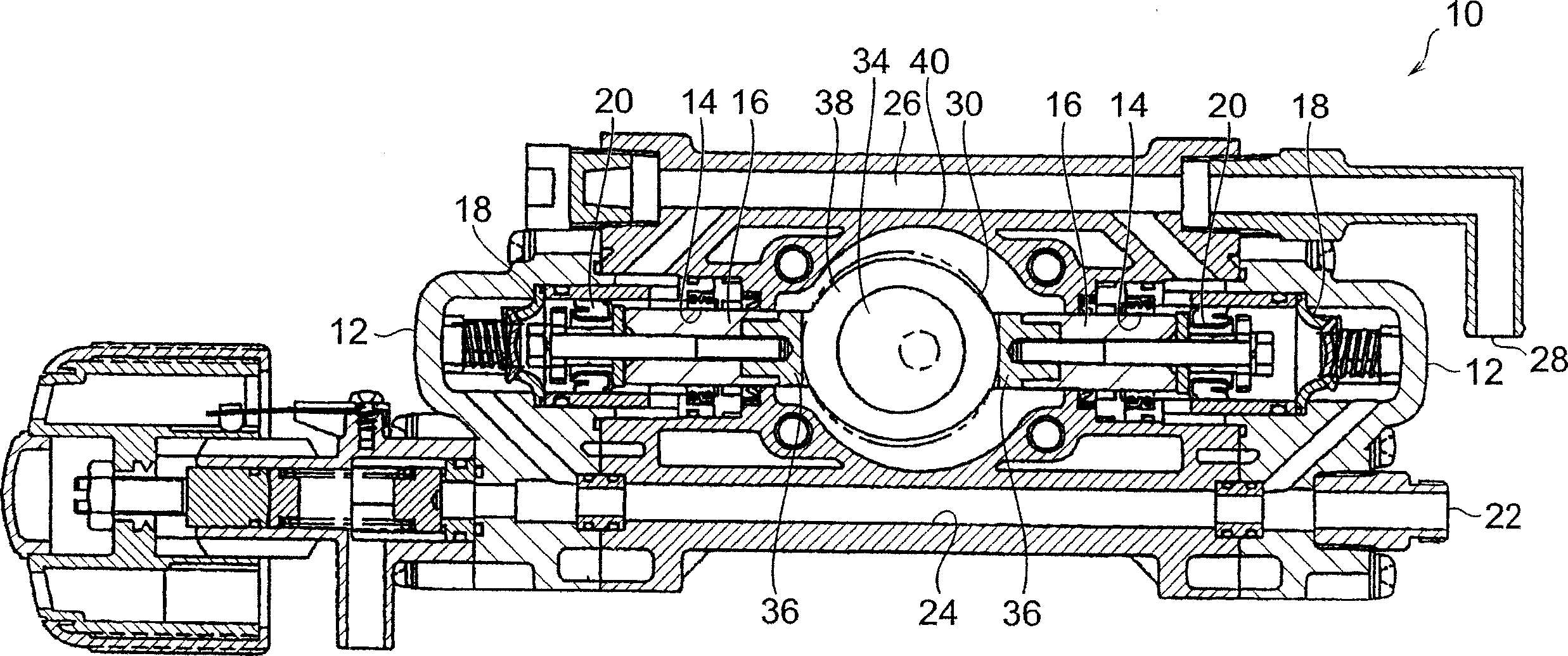

[0016] figure 2 is a partial sectional view of the reciprocating pump device of the present invention, image 3 is along figure 2 Partial sectional view of line III-III in. In the illustrated reciprocating pump device 10 , two reciprocating pumps 12 are arranged in a row in a state facing each other. Each reciprocating pump 12 includes: a hydraulic cylinder 14, a piston 16 reciprocating in the hydraulic cylinder 14, a discharge valve 18, and a suction valve 20; wherein, through the reciprocating movement of the piston 16, the liquid passes through the flow path 24 from the suction port 22, And flow through the flow path 26 and be discharged from the drain port 28 . Since the reciprocating pumps 12 operate alternately, the liquid is continuously supplied to the flow path 26 , so that the liquid is efficiently and stably discharged from the drain port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com