Filling bed type gas electrically heating device

An electric heating device and packed bed technology, applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of reducing the safety performance of the electric heating system, no direct heat exchange, low heat exchange efficiency, etc., to achieve The effects of increasing temperature, reducing concentrated heat transfer, and increasing heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following embodiments of the present invention are only used to illustrate the technical solutions of the present invention, and they should not limit the protection scope of the present invention. Any equivalent transformation made to the technical solutions of the following embodiments should belong to the protection scope of the present invention.

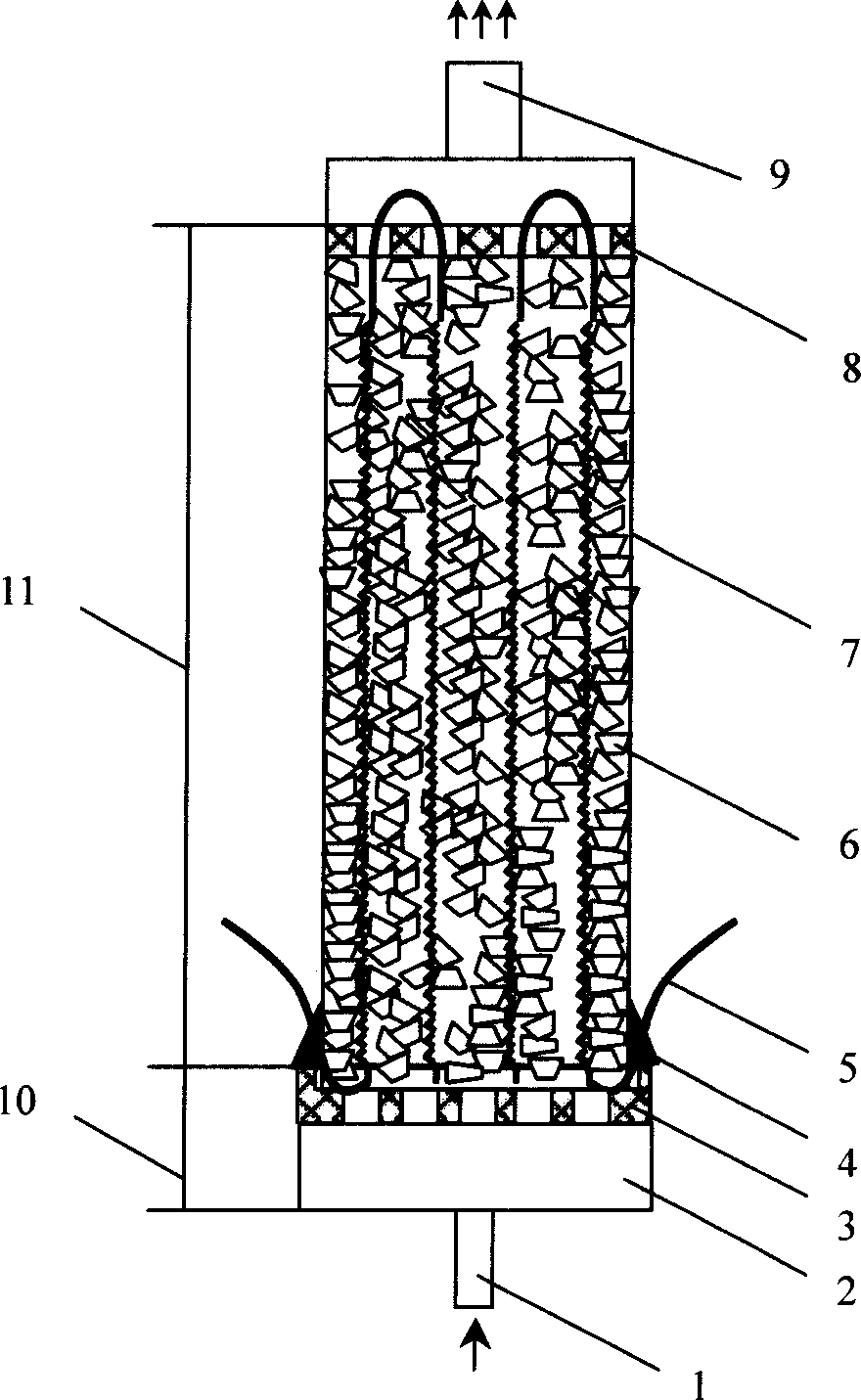

[0014] Such as figure 1 As shown, the present invention includes: air inlet 1, air chamber 2, air distribution plate 3, concrete refractory mud 4, resistance wire 5, electrical insulation and heat conduction bulk material 6, pipeline 7, resistance wire folded back support plate 8, air outlet 9, Air distribution area 10 and heating area 11. The connection relationship is:

[0015] The bottom of the pipe 7 is a horizontal uniform air distribution plate 3. According to the shape of the cross section of the pipe 7, a groove is made on the air distribution plate 3, and the pipe 7 is arranged in the groove; or a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com