Screwdriver device and screw

A screw and screw head technology, applied in the direction of screws, nuts, bolts, etc., can solve problems such as difficulty in obtaining fastening force, damage to the appearance of mechanical products, and loose screws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

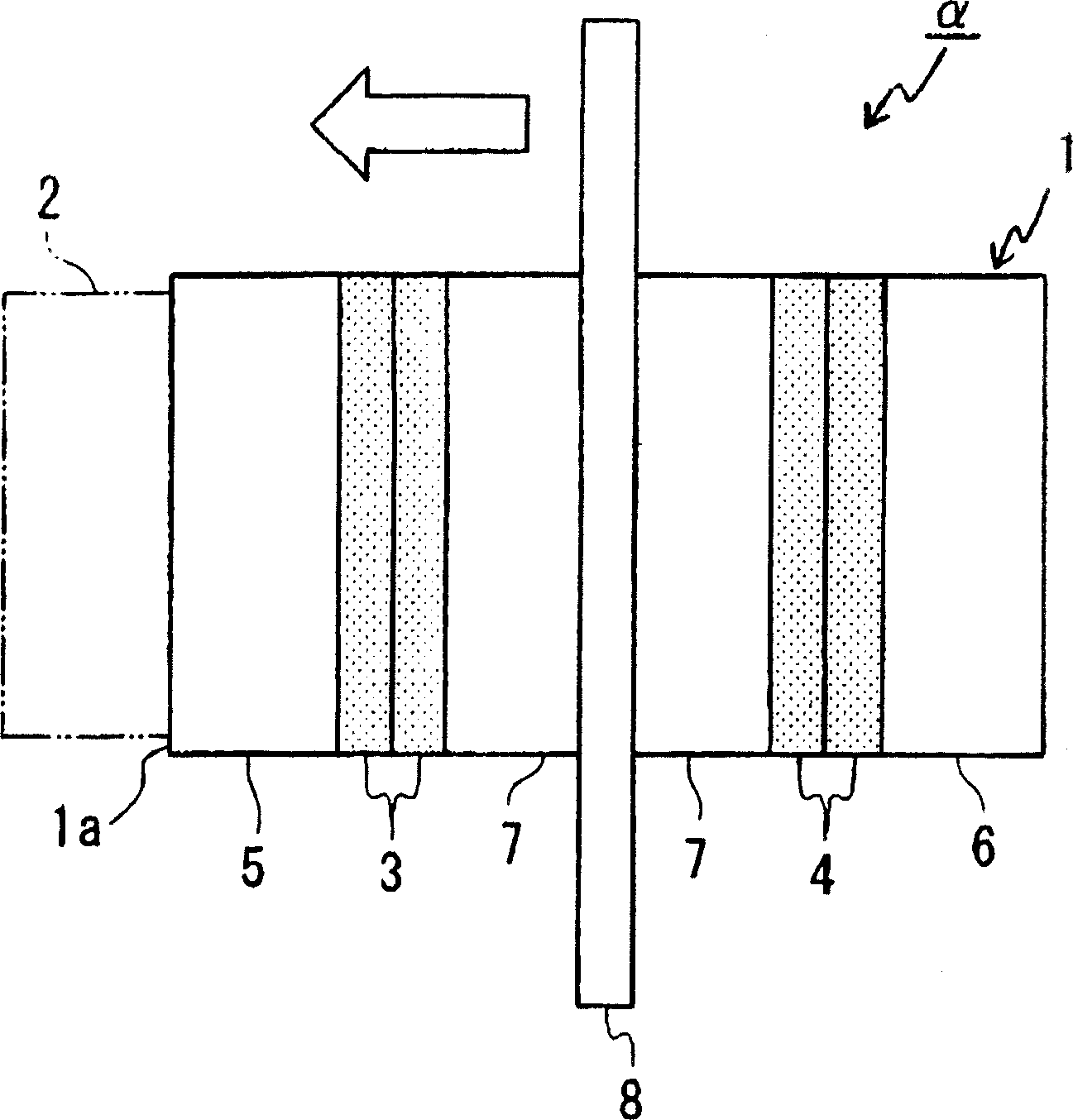

[0192] First, as the first embodiment, using figure 1 The basic idea of the screw driving device of the present invention will be described. The screw turning device α is used to fasten or loosen the screw relative to the corresponding threaded hole formed on any part to be fastened. It has a device main body 1 and an Vibration-transmitting mechanism 2 for contact.

[0193] The device main body 1 is composed of a plurality of piezoelectric elements 3, 4 that generate flexural vibration in two directions perpendicular to each other, an end vibrating member 5 and a rear end vibrating member 6, two central vibrating members 7, 7, and The flange members 8 are stacked and fastened with bolts (not shown).

[0194] A predetermined AC voltage is applied from an AC power source (not shown) to a plurality of piezoelectric elements 3, 4..., and ultrasonic vibrations are generated thereupon. (i.e., screws ( figure 1 Not shown in the figure)) performs a rotational movement around an ...

no. 2 Embodiment approach

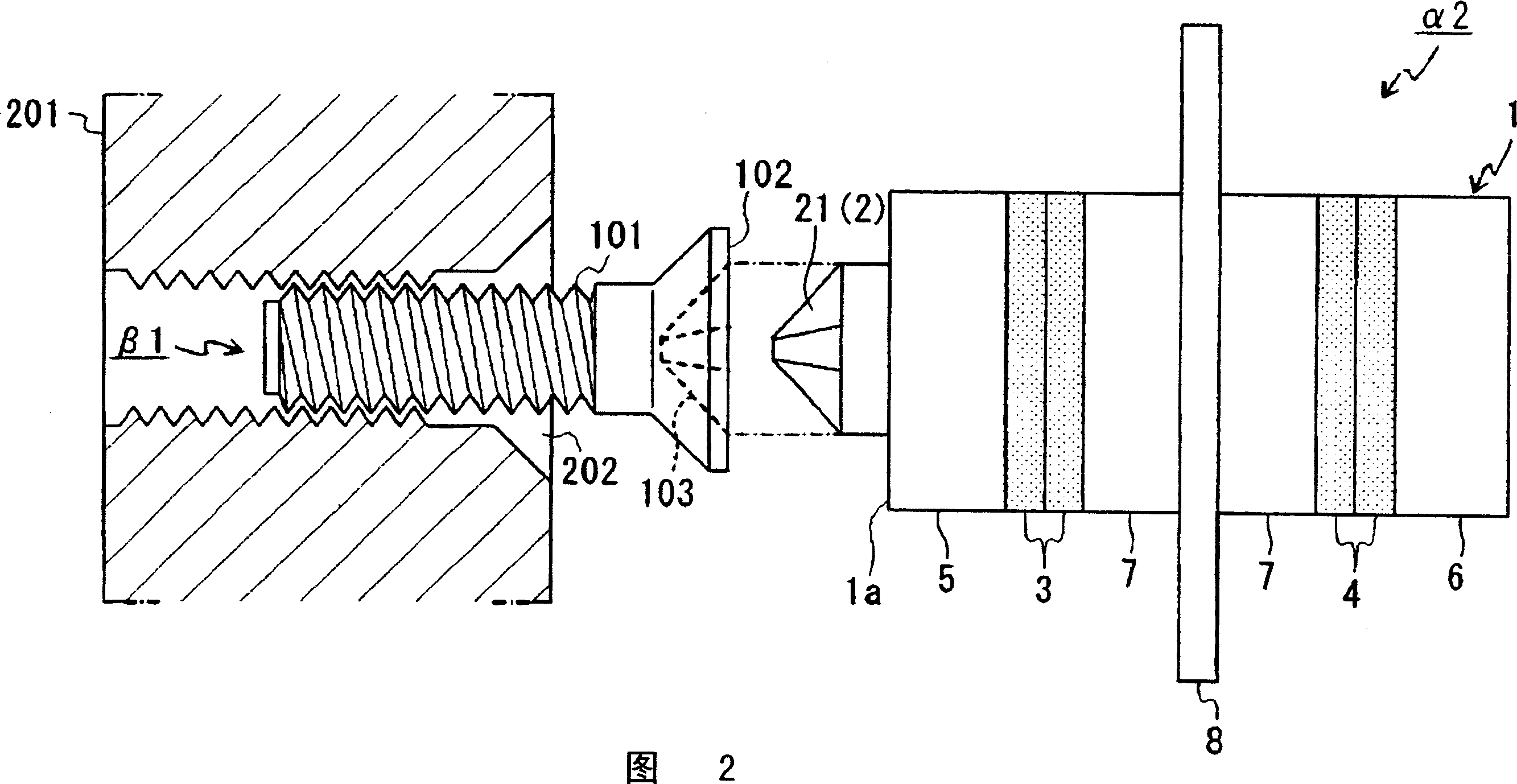

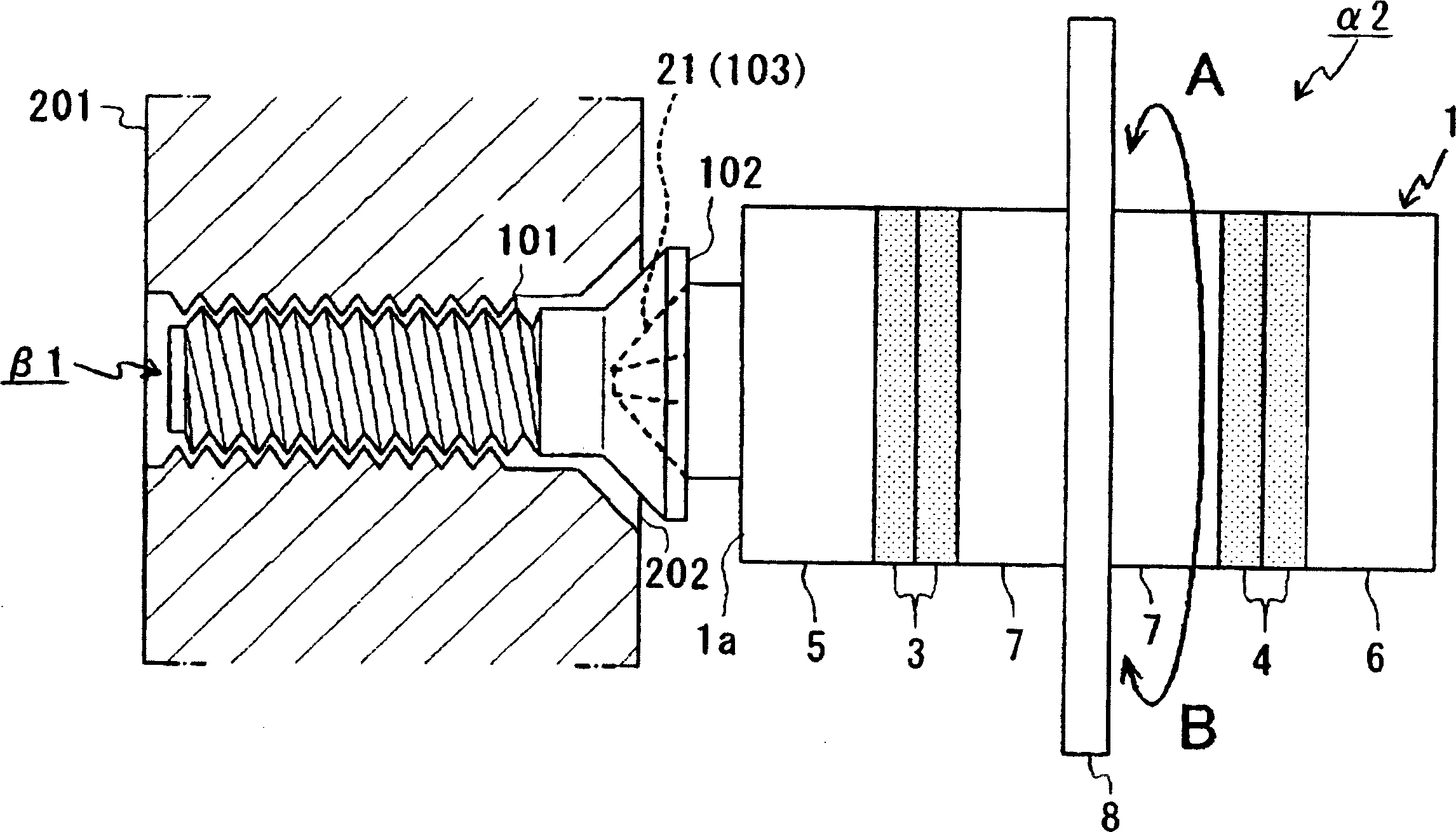

[0206] Next, as a second embodiment of the present invention, using FIG. 2 and image 3 , an application example of the screw driving device described in the above-mentioned embodiment will be described.

[0207] This screw driving device α2 is an example that has, as the above-mentioned vibration transmission mechanism 2 , a convex end portion 21 fitted with a concave inscription engraved on the screw head.

[0208] In addition, in this embodiment, the same code|symbol is attached|subjected to the component common to the component of the above-mentioned embodiment, and the detailed description is abbreviate|omitted.

[0209] Fig. 2 is a view showing the structure of main parts and its usage state of a screw driving device according to a second embodiment of the present invention, and is a partial cross-sectional side view showing through predetermined concave markings formed on the screw head.

[0210] As shown in the figure, the screw driving device α2 of the present embodi...

no. 3 Embodiment approach

[0230] Next, as the third embodiment of the present invention, using Figure 4A ~ Figure 10 Another application example of the screw driving device shown in the above-mentioned embodiment and a screw corresponding thereto will be described. In this embodiment, as an example of a screw, the first to sixth examples of a screw driving device for fastening the screw of this example are sequentially cited and described.

[0231] In addition, in this embodiment, the same code|symbol is attached|subjected to the component common to the component of each embodiment mentioned above, and the detailed description is abbreviate|omitted.

[0232] First, regarding the screw of this embodiment, in Figure 4A ~ Figure 4C Indicated.

[0233] Figure 4A ~ Figure 4C It is a figure which shows the form of the screw and the corresponding structural member of this embodiment, wherein, Figure 4A It is a cross-sectional view of a structural member as an example of a fastened member for fastening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com