Outboard machine driven by triangle rotor engine

An engine-driven, triangular rotor technology, applied in the field of outboard motors, can solve the problems affecting the speed of speedboats, heavy weight, and large volume, and achieve the effects of light weight, low vibration and noise, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

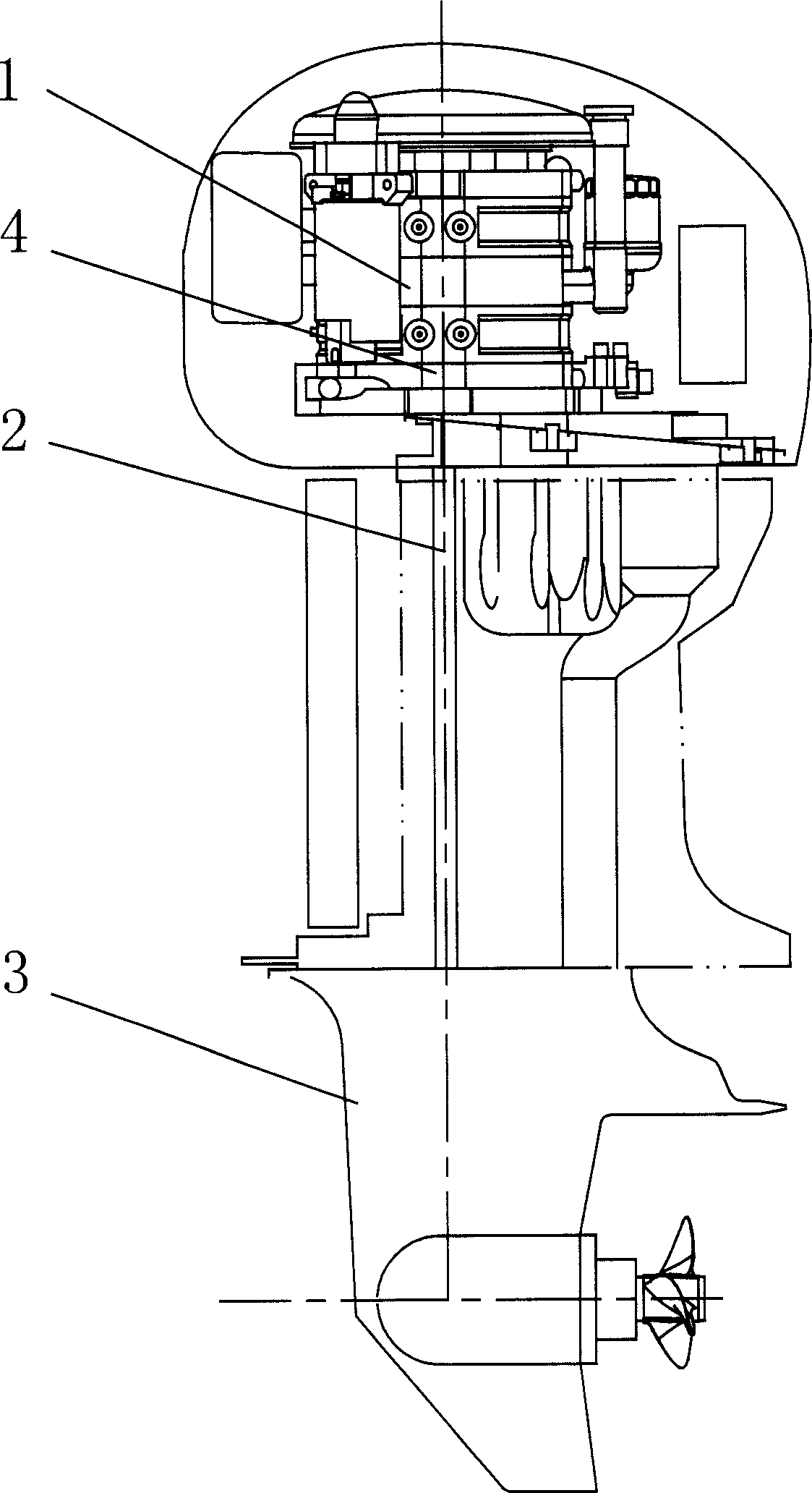

Embodiment 1

[0014] Embodiment 1 is: an outboard engine driven by a triangular rotor engine, including a triangular rotor engine 1 located on the top of the outboard engine, the triangular rotor engine drives an underwater power output mechanism 3 through a transmission shaft 2, and the output shaft 4 of the triangular rotor engine It is connected coaxially with the transmission shaft 2.

[0015] During use, the output shaft 4 of the triangular rotor engine directly drives the transmission shaft 2 to rotate at a constant speed.

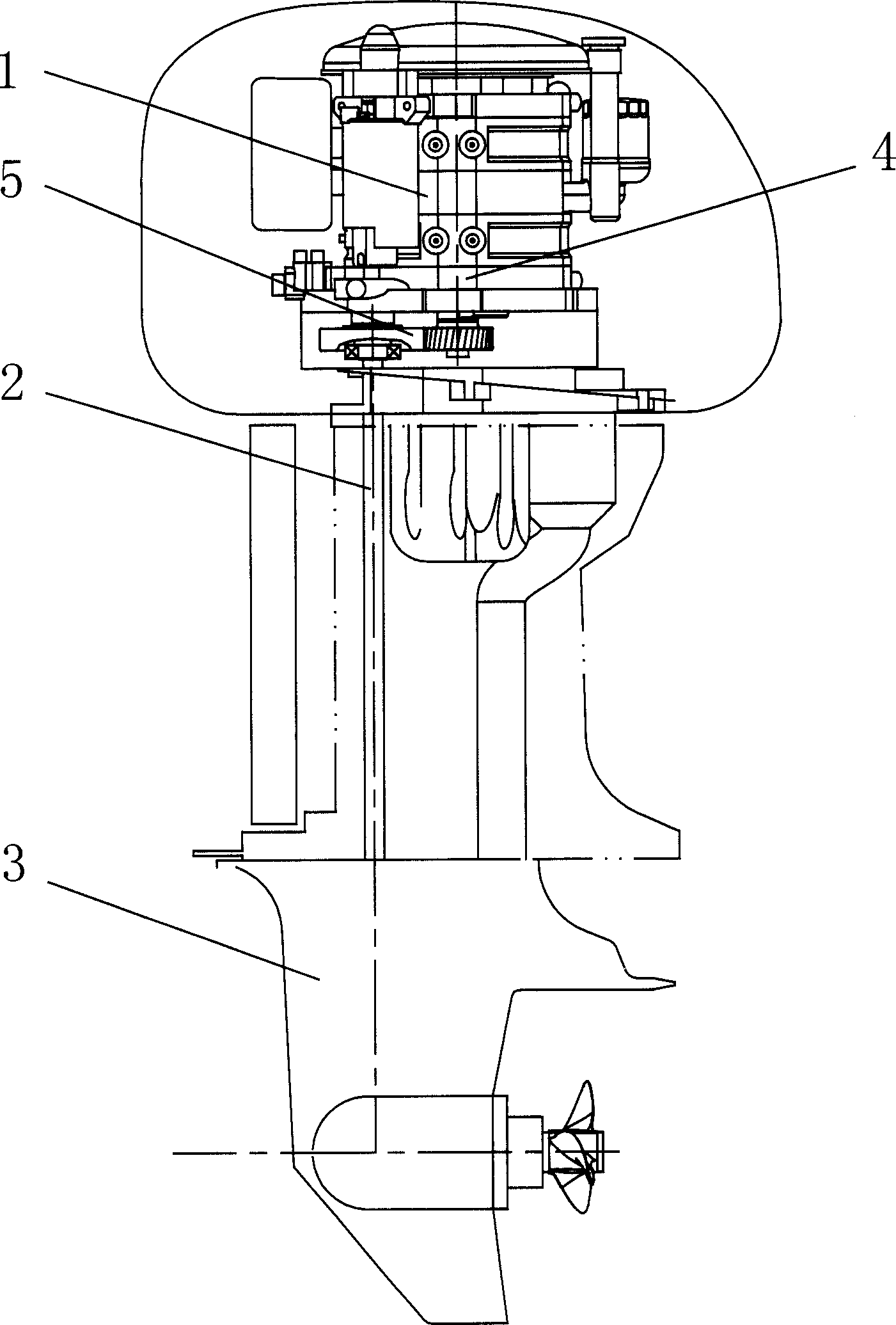

Embodiment 2

[0016] Embodiment 2 is: an outboard engine driven by a triangular rotor engine, including a triangular rotor engine 1 located on the top of the outboard engine, the triangular rotor engine drives an underwater power output mechanism 3 through a transmission shaft 2, and the output shaft 4 of the triangular rotor engine It is connected with the transmission shaft 2 through the reduction gear 5.

[0017] During use, the output shaft 4 of the triangular rotor engine indirectly drives the transmission shaft 2 to decelerate and rotate through the reduction gear 5 .

[0018] Compared with the reciprocating engine, the triangular rotor engine of the present invention cancels the useless linear motion, so the rotor engine with the same power is smaller in size, lighter in weight, and has lower vibration and noise, which avoids driving problems caused by heavy weight. The occurrence of a slowdown.

[0019] The output shaft 4 of the triangular rotor engine of the present invention can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com