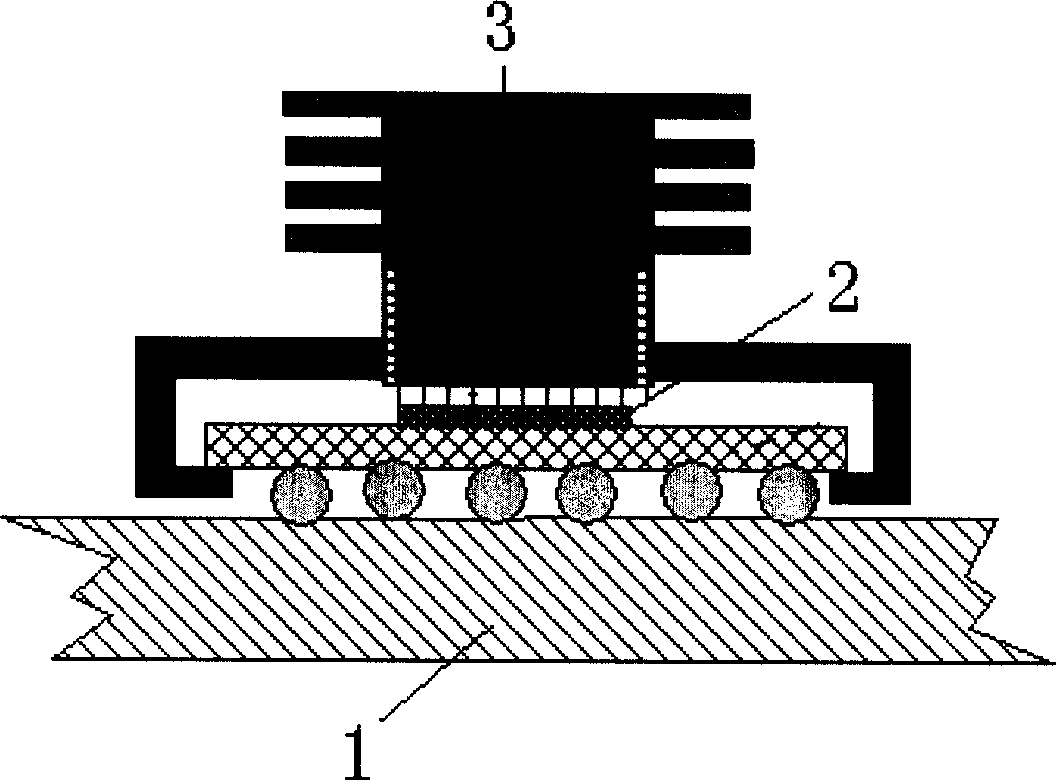

Thermal rubber heat sink and its manufacturing method and circuit board and its manufacturing method

A production method and technology of thermally conductive adhesive, which are applied in the directions of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of short circuit, loud noise, ion pollution, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

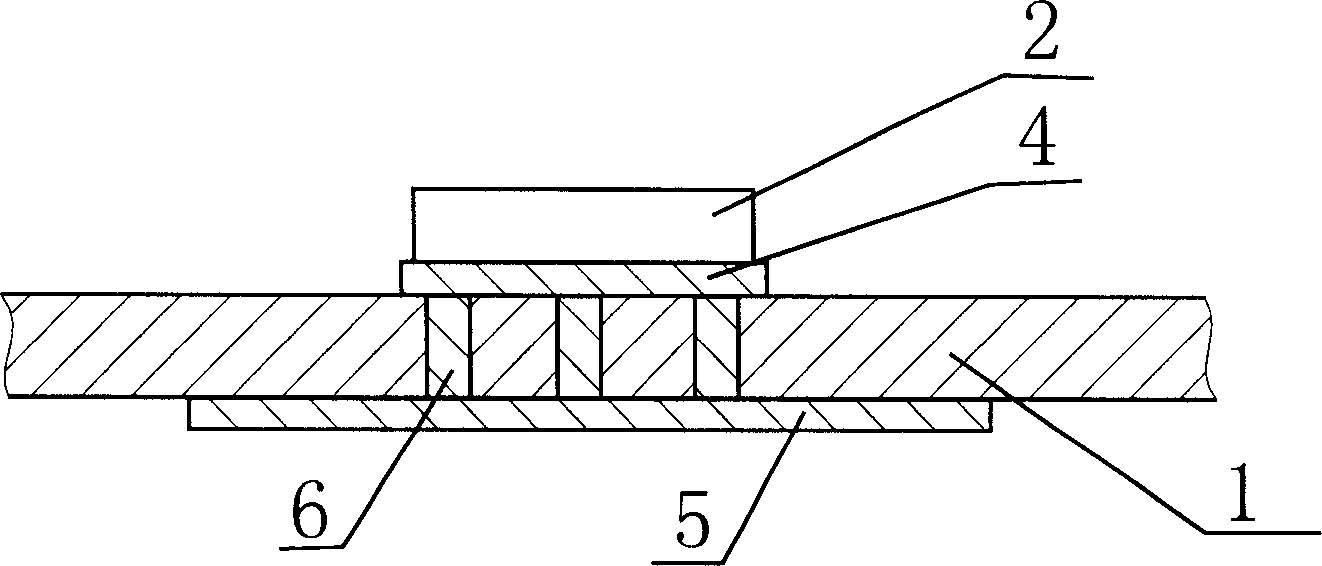

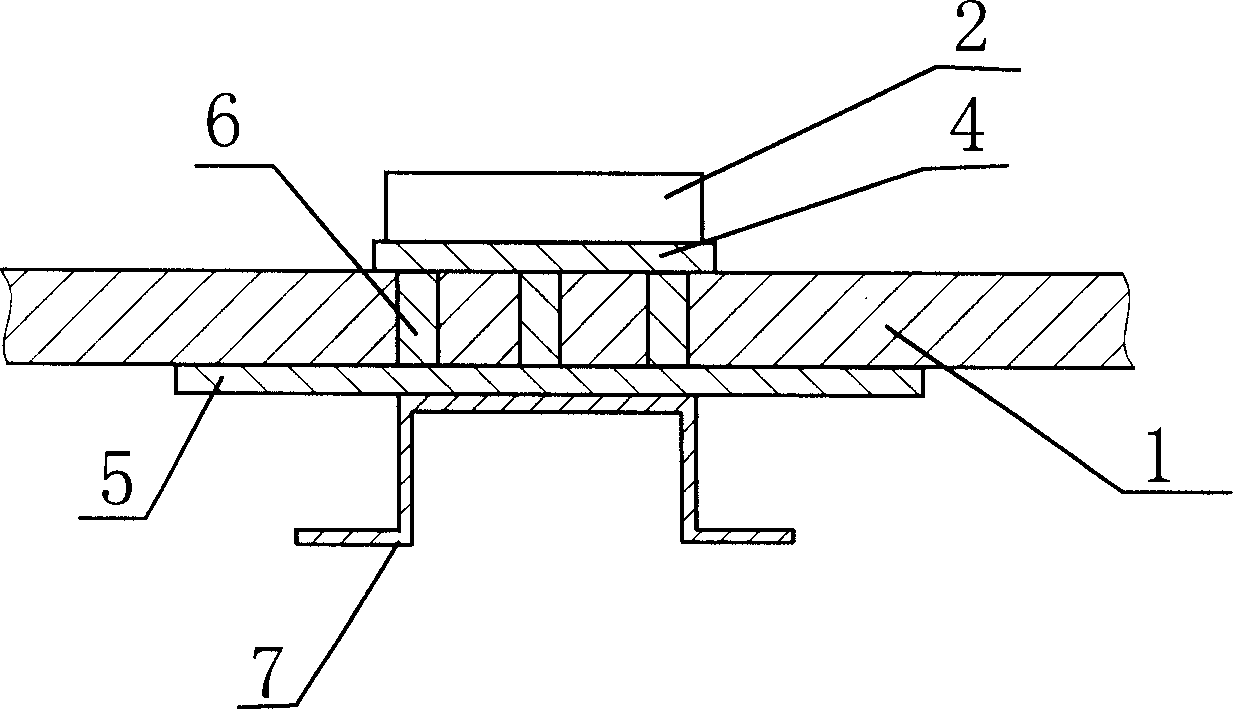

[0044] A preferred embodiment of the present invention is:

[0045] The thermally conductive glue radiator is designed as a sheet structure, made of thermally conductive glue that meets the predetermined requirements and is insulated. The predetermined thermal conductivity of the thermally conductive glue is selected according to the heat dissipation requirements of the device that needs to be dissipated. The thermal conductivity is greater than 0.5W / mK is enough, the preferred range is 2~5W / mK, the definition of thermal conductivity is: how much W energy can be transmitted per m length and per K temperature, and the unit is W / mK. Among them, "W" refers to the unit of thermal power in watts, "m" refers to the unit of length in meters, and "K" refers to the unit of absolute temperature. The larger the thermal conductivity, the better the thermal conductivity.

[0046] There are two ways to make and install thermal paste radiators:

[0047] One is the flow coating method: hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com