Small-scaled high-pressure natural gas well processing and utilization system

A natural gas and well treatment technology, which is applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve safety hazards and other problems, and achieve the effects of eliminating safety hazards, low investment costs, and huge social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

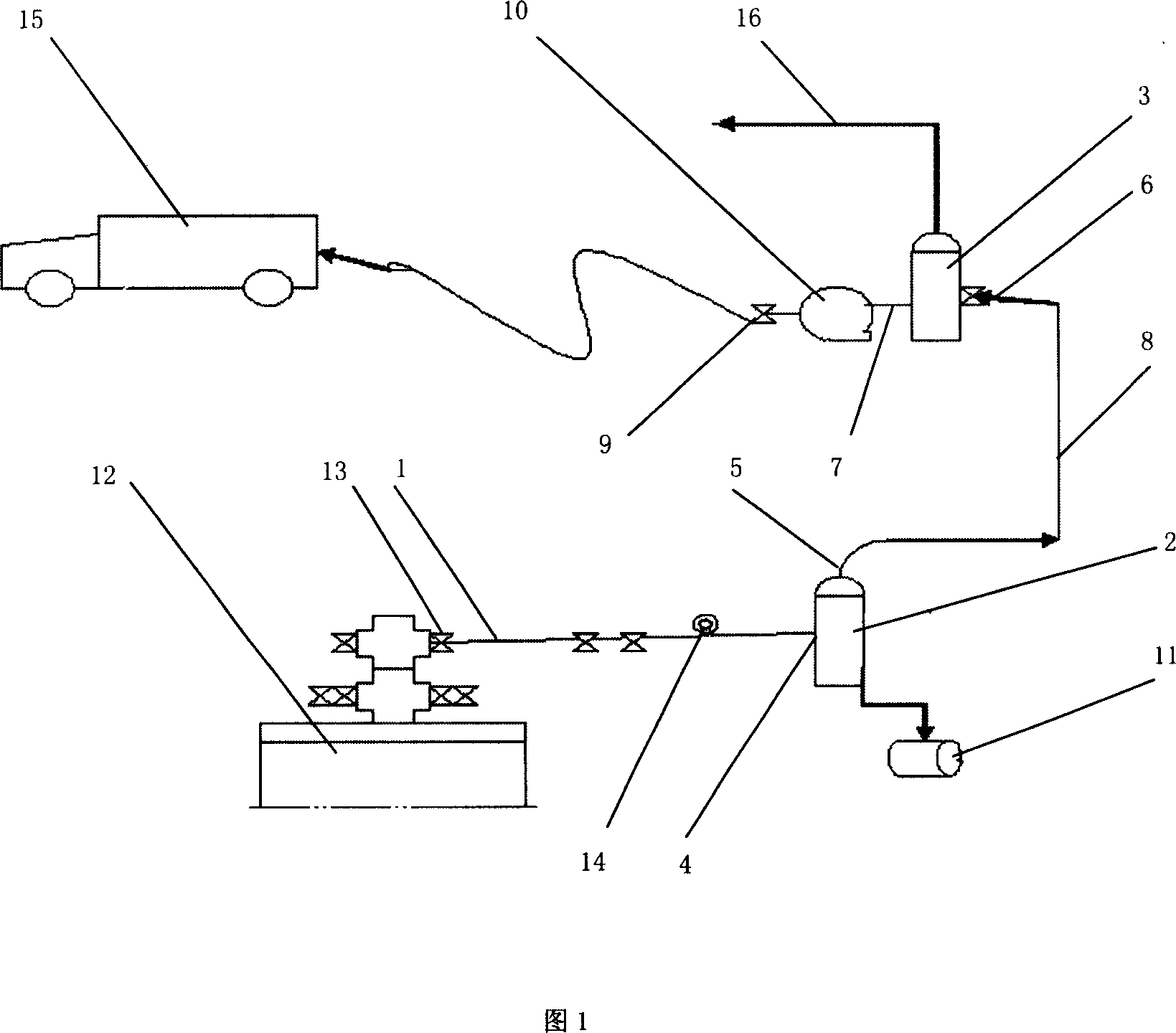

[0028] As shown in FIG. 1 , the small-scale high-pressure natural gas well treatment and utilization system in this embodiment includes a natural gas well gas extraction pipe 1, a natural gas filtration, dehydration separator 2 and a natural gas separation dryer 3. The natural gas filtration and dehydration separator 2 has The gas inlet 4 and the gas outlet 5, the natural gas separation dryer 3 has a gas inlet 6 and a gas outlet 7, and the natural gas well gas extraction pipe 1 is communicated with the gas inlet 4 of the natural gas filtration and dehydration separator. The gas outlet 5 of the natural gas filtration and dehydration separator is communicated with the gas inlet 6 of the natural gas separation dryer through a communication pipe 8 , and the gas outlet 7 of the natural gas separation dryer is controlled by a gas valve 9 .

[0029] In this embodiment, a gas pressurizing device 10 (in this example, an automobile CNG compressor) is also provided at the gas outlet 7 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com