Control device for electric controlled automatic shift for vehicle variator

An automobile transmission and automatic gear shifting technology, which is applied to the transmission device, transmission device control, gear transmission device, etc., can solve the problems that the working performance is greatly affected by temperature changes, the volume of the motor and the reduction mechanism is large, and the power performance of the vehicle is reduced. Achieve the effects of shortening the shifting process time, strong adaptability and versatility, and improving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

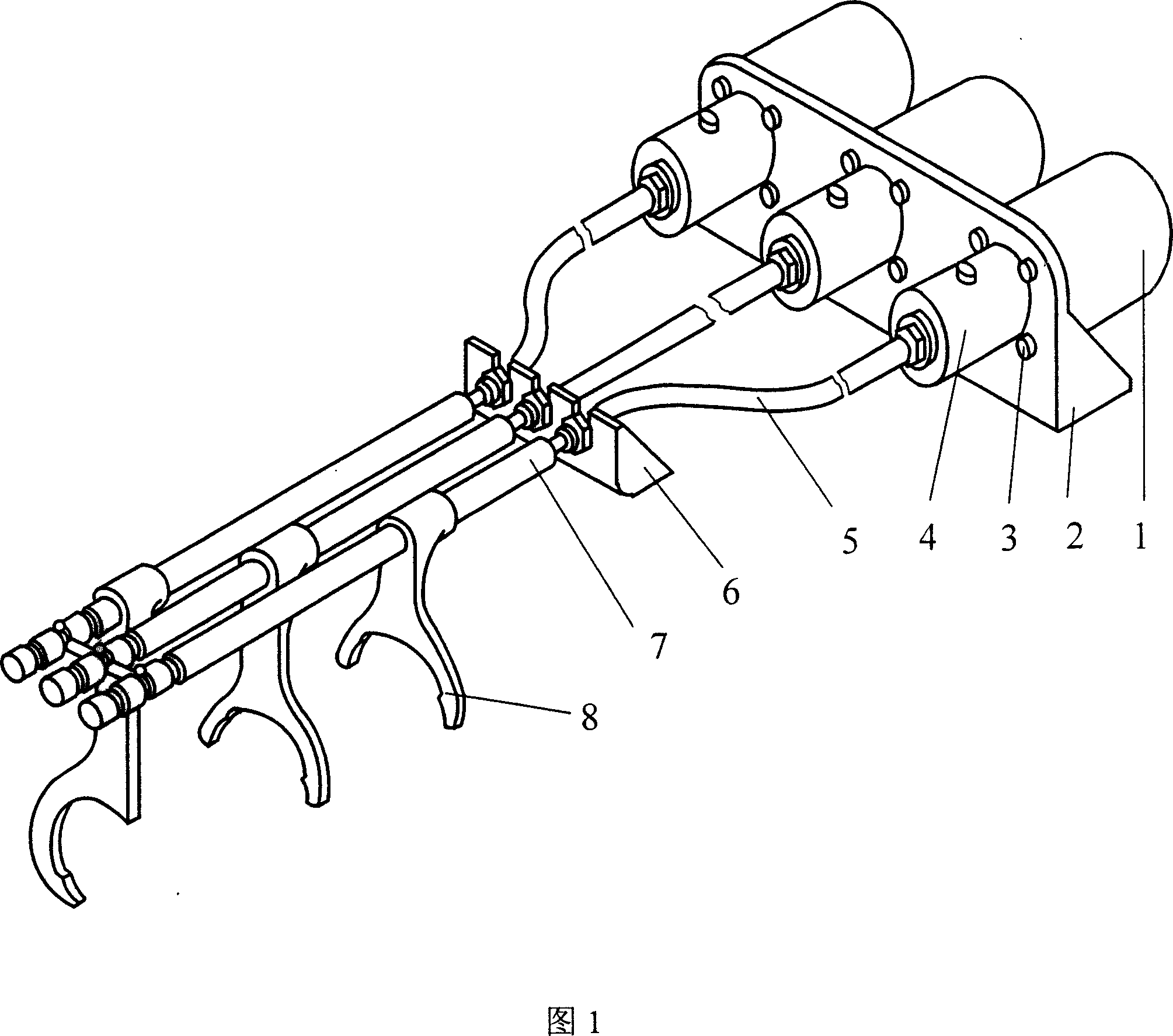

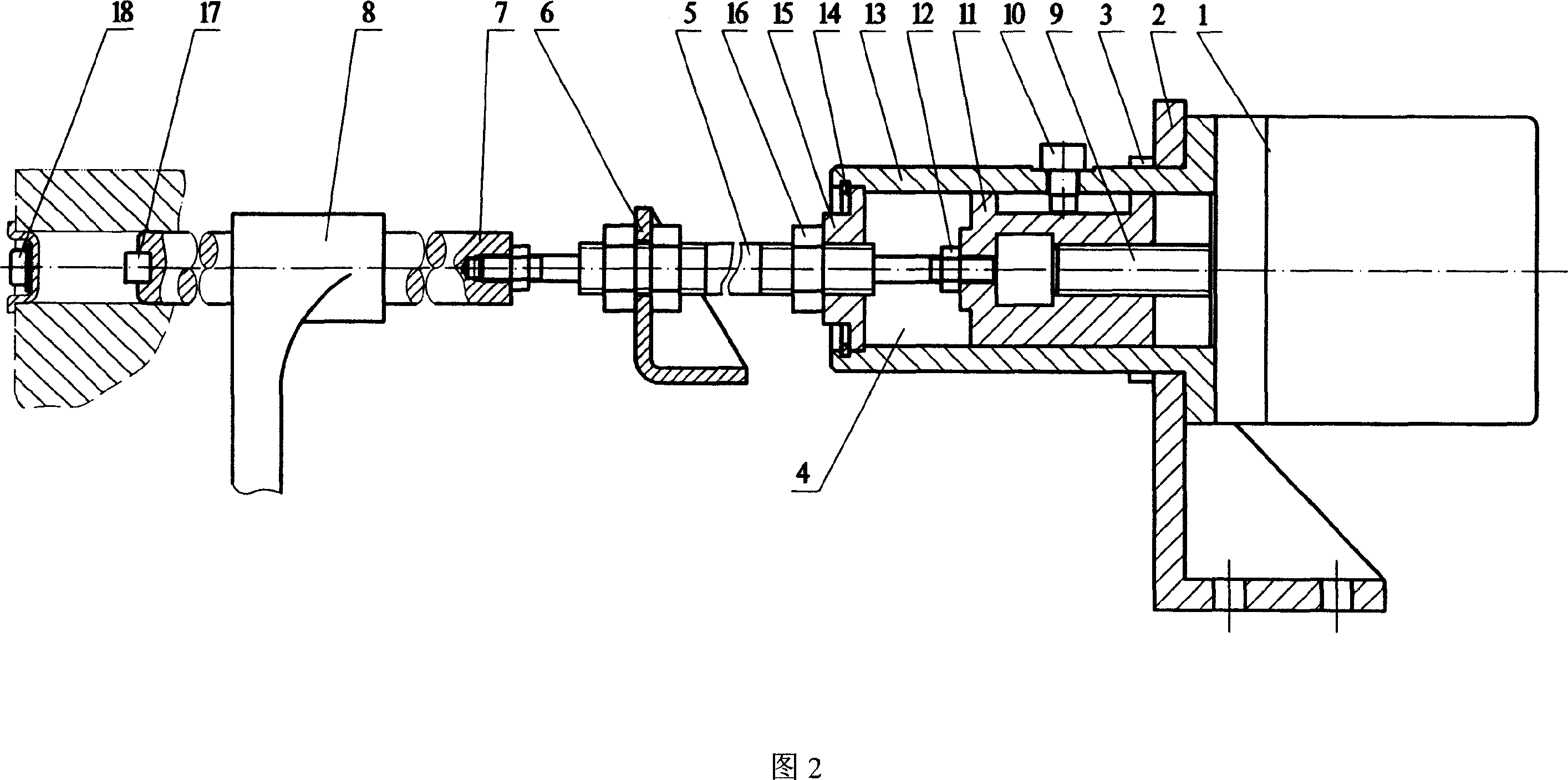

[0013] Embodiment 1: The screw nut is used as the deceleration mechanism (Fig. 2), the motor shaft 9 is a screw rod, the deceleration mechanism housing 13 is a cylinder with a flange at one end, and a radial threaded hole for installing a limit screw 10 in the middle , a cylindrical sliding nut 11 is installed in the housing 13, the right end of the inner hole of the sliding nut has a thread matched with the screw rod of the motor shaft 9, an axial limit groove is opened on the outer cylindrical surface, and a push-pull flexible shaft 5 is connected to the left end. The internal thread of the inner core, the outer cylindrical surface of the sliding nut and the inner hole of the housing 13 are clearance fit, the sliding nut 11 can move axially in the housing 13 but cannot rotate under the drive of the motor 14 and the limitation of the limit screw 10 . The end cap 15 is a disc with threaded holes, and is fixed on the left end of the housing 13 through the elastic retaining ring...

Embodiment 2

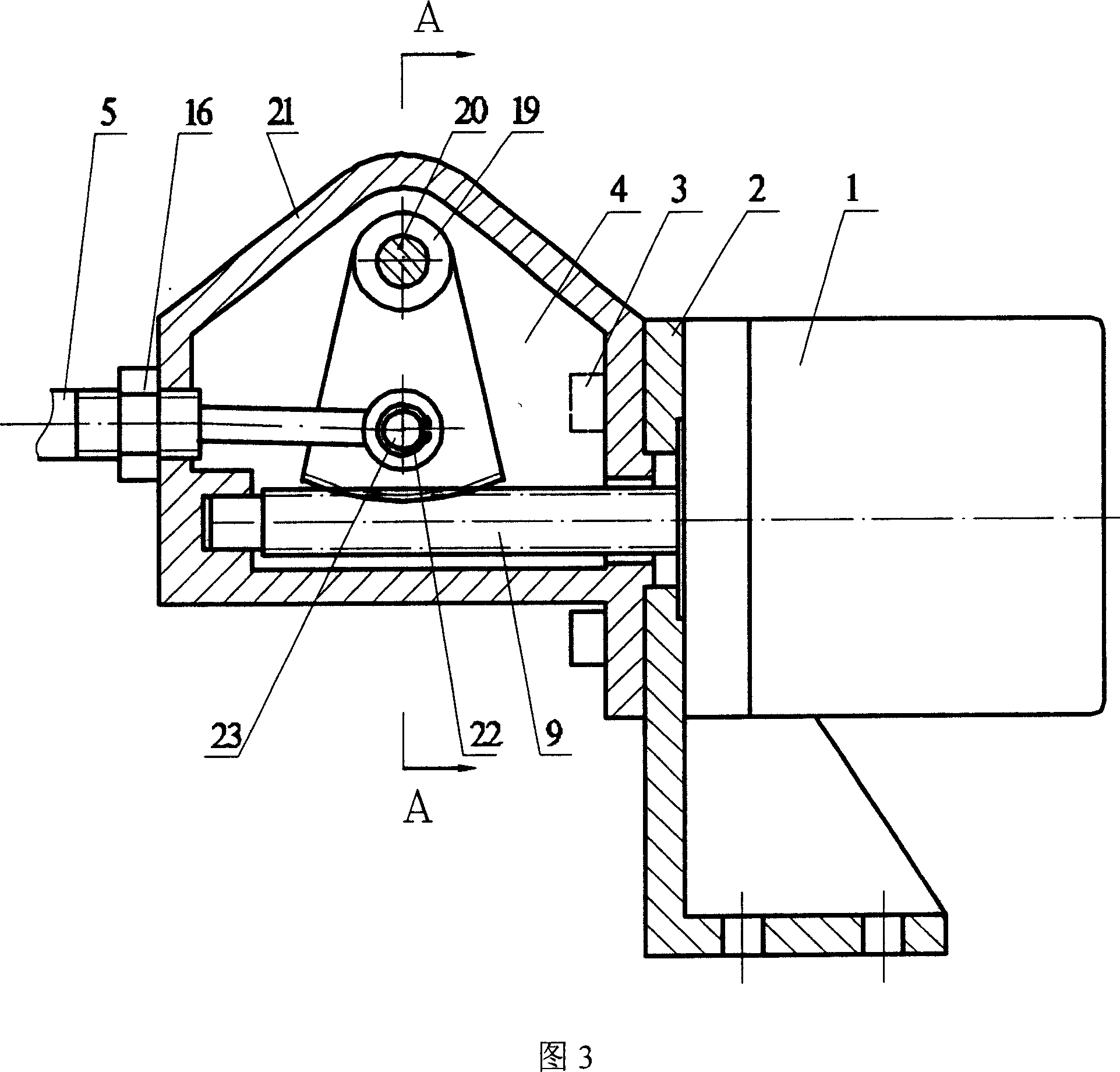

[0014] Embodiment 2: Adopt worm gear as deceleration mechanism (Fig. 3, Fig. 4), worm gear deceleration mechanism housing 21 has connecting flange, connects it with fixed bracket 2 and motor 1 by screw 3, and is installed in engine compartment Inside or on the vacancy of the vehicle frame, the fan-shaped worm gear is installed on the worm gear shaft fixed between the housing 21 and the cover plate 24, and can rotate around the worm gear shaft. The worm gear is fixed with a flexible shaft hinge pin 23, and the motor output shaft 9 is a The worm meshed with the worm gear 19, the right end of the inner core of the push-pull flexible shaft 5 is an earring, installed on the hinge pin 23 of the flexible shaft and positioned with the elastic retaining ring 22, the shell of the push-pull flexible shaft 5 is installed on the threaded hole of the housing 21 and locked with a nut 16 . The motor can rotate forward and reverse under the drive of the electronic control unit, and the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com