Method for forming photoinduced resist pattern

A technology of photoresist and photoresist layer, which is applied in the photoengraving process, optics, optomechanical equipment and other directions of the pattern surface, and can solve the problems of tightening of the end of the straight line, residual pattern of auxiliary, circularization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

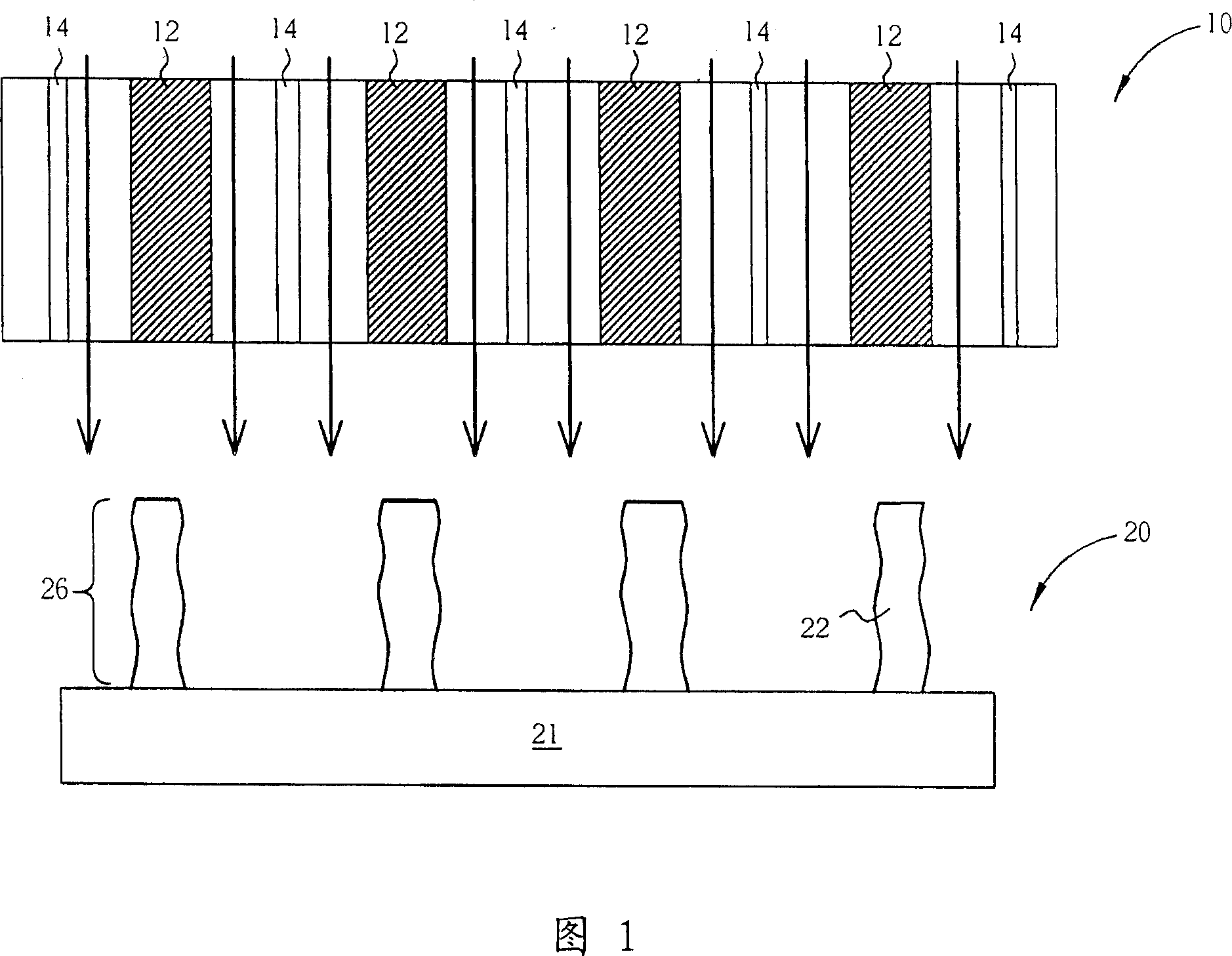

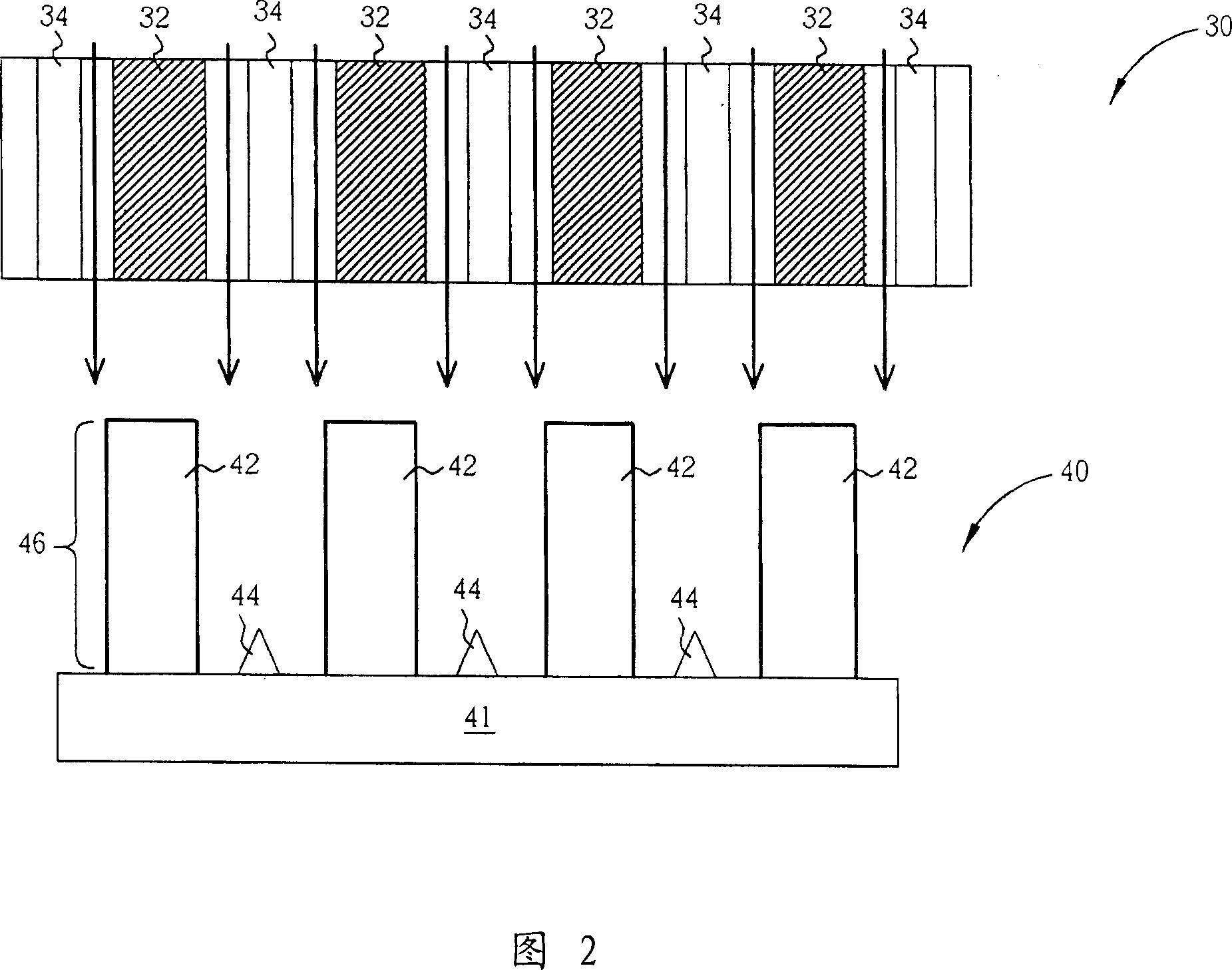

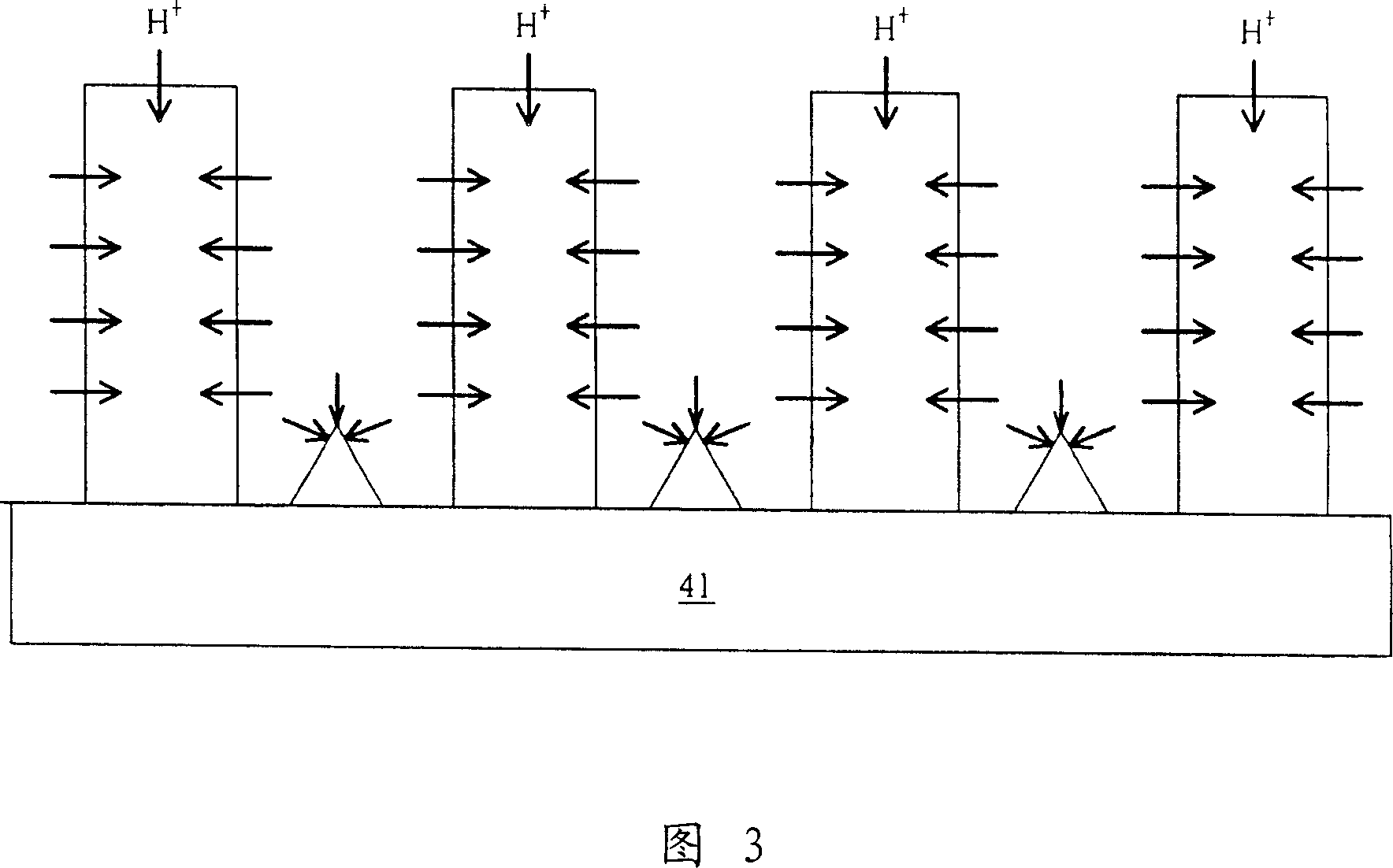

[0021] Please refer to FIGS. 2 to 4. FIGS. 2 to 4 are schematic diagrams of the process of forming a photoresist pattern of the present invention. The photomask 30 in FIG. 2 has at least one main feature 32. There are auxiliary patterns 34 between the main patterns 32. The auxiliary patterns 34 can be composed of serifs, scattering bars, etc. In addition, the semiconductor wafer 40 has a substrate 41. The design of the main pattern 32 must consider the projection magnification of the exposure machine (not shown), the correction of the optical proximity effect (OPE, optical proximity effect), the auxiliary pattern (assistant feature) 34, and the shrinking step ( trim process). After the ideal photomask layout pattern is calculated by the computer, the main pattern 32 is output on the photomask 30. At present, the industry generally uses a projection exposure machine as a photolithography exposure machine, and most of them use CAD computer-aided design to calculate the photomask pat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com