Connector welding seam ray detection and location device for nuclear power station voltage regulator fluctuation pipe

A radiographic inspection and positioning device technology, applied in nuclear power generation, nuclear engineering, nuclear reactor monitoring, etc., can solve problems such as the inability to find the detailed information of the positioning tool and the technology used, export restrictions, and the inability to learn from design experience, etc., to improve positioning. Reliability, fast positioning speed and good positioning reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

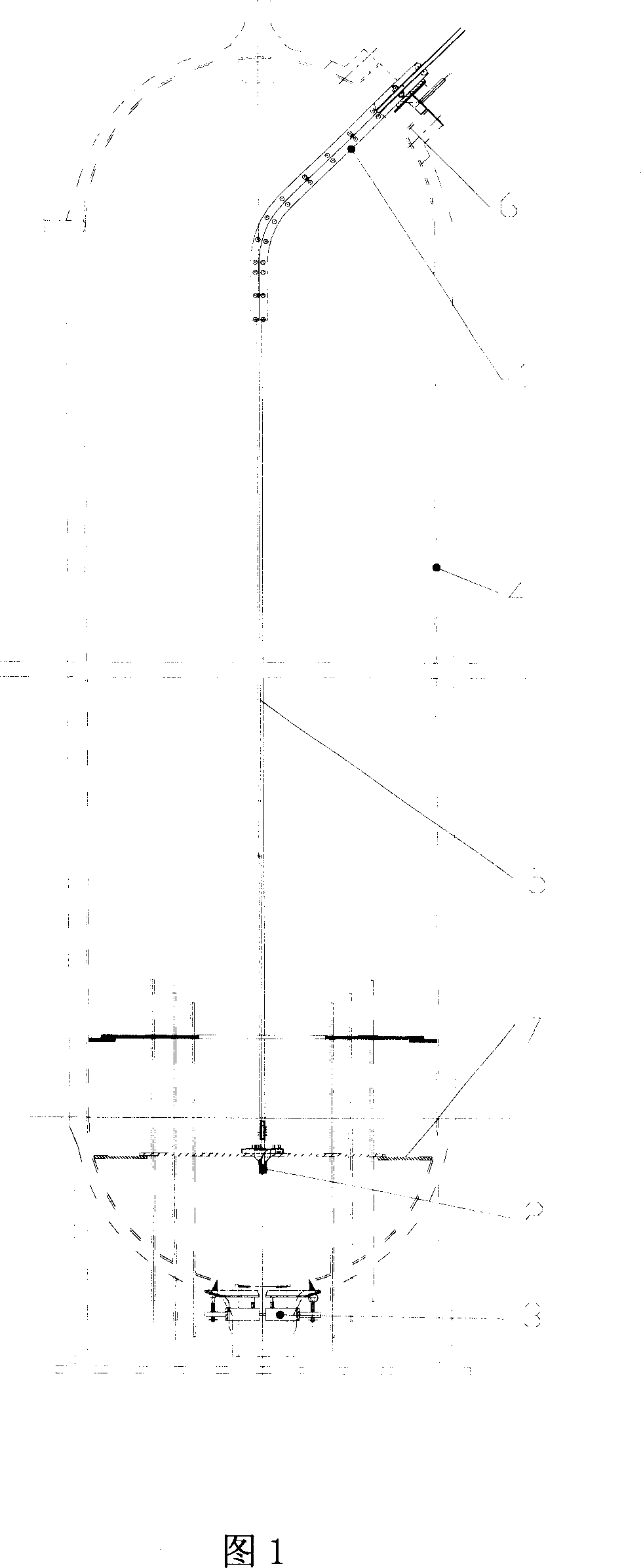

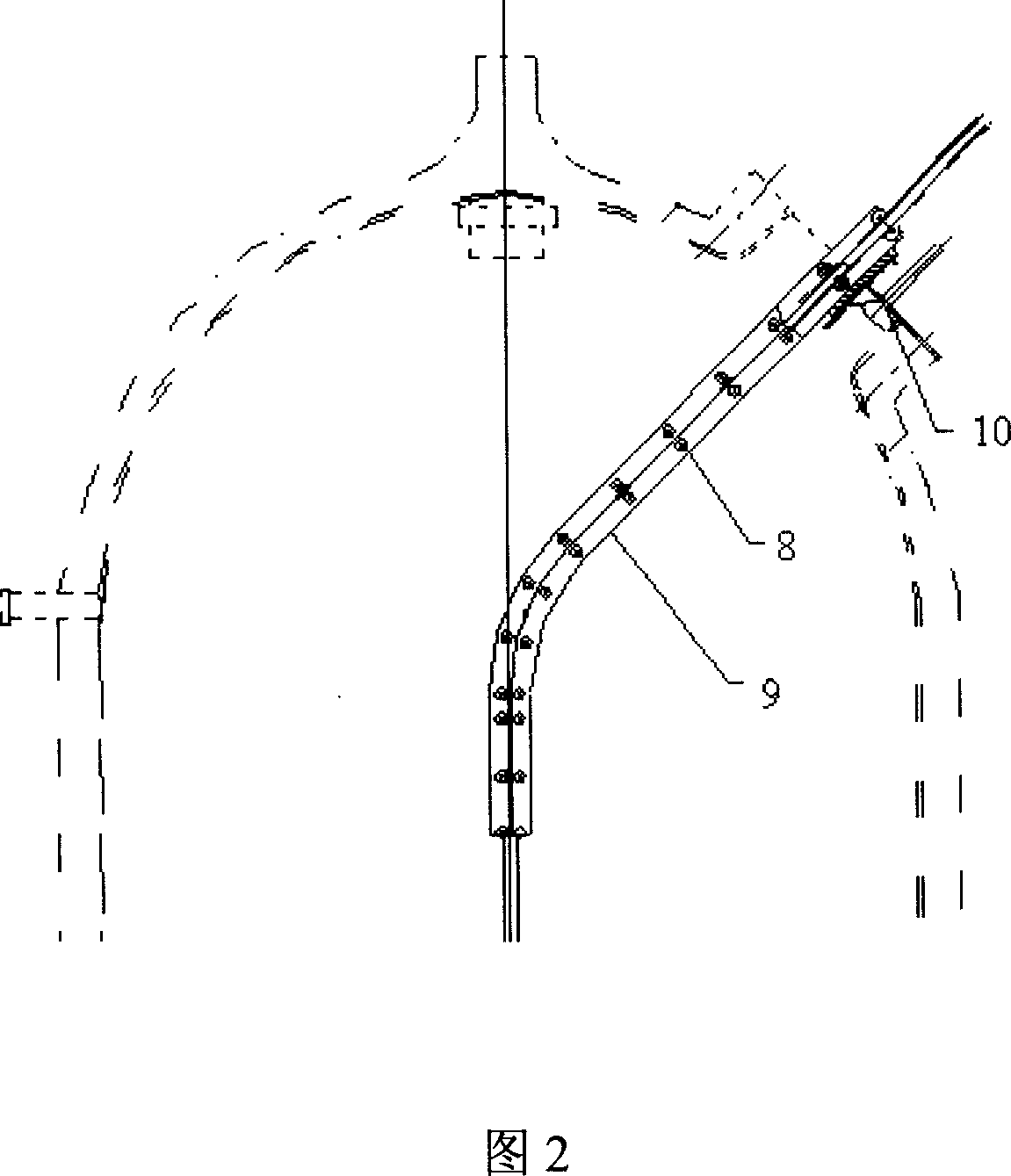

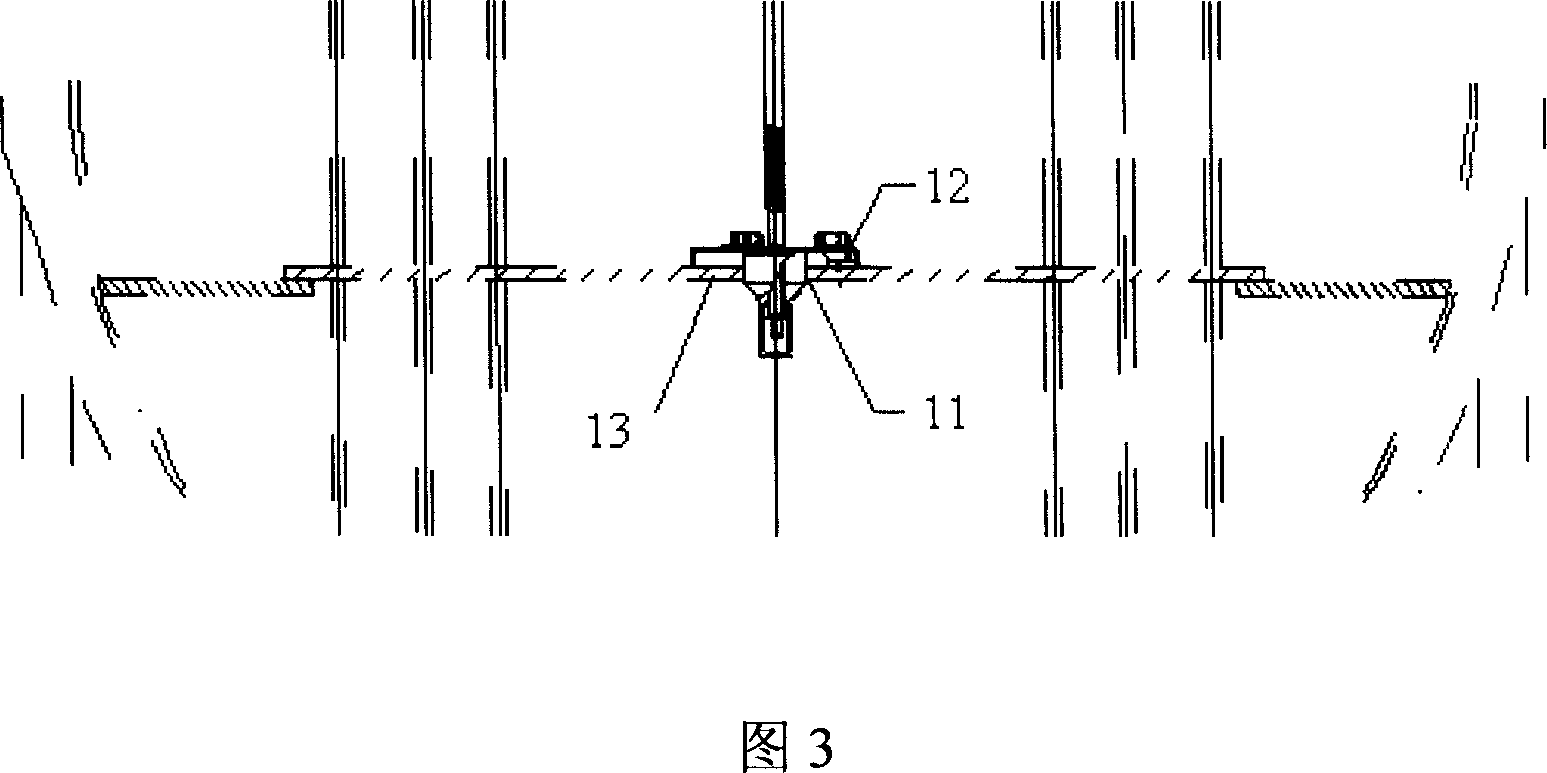

[0014] As shown in Figures 1 to 5, a radiographic inspection and positioning device for the surge pipe weld seam of a nuclear power plant voltage stabilizer includes a double-pulley manhole support and positioning frame 1 fixed on the manhole flange surface 6, and a double-pulley manhole support and positioning The frame 1 includes a manhole support seat 10 connected with the manhole flange surface 6, and the double pulley manhole support positioning frame (1) is connected with the manhole flange surface (6) by bolts. The center of the manhole support seat 10 is connected with a double pulley guide rail seat 9, and a double pulley block 8 is arranged in the double pulley guide rail seat 9. In the middle of the double pulley block 8 is a flexible sleeve 5, and in the flexible sleeve 5 is a ray source transmission source tube and sensor cable. The lower end of the flexible sleeve 5 is connected to the radiation source positioning socket 2, and three sensors are uniformly distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com