Method and tools for low-speed milling without irrigation and with extraction and recovery of tissue particles

A grinding method and technology of grinding tools, which are applied in medical science, dentistry, surgery, etc., can solve problems that affect the success of surgery, the length of time for bones and implants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

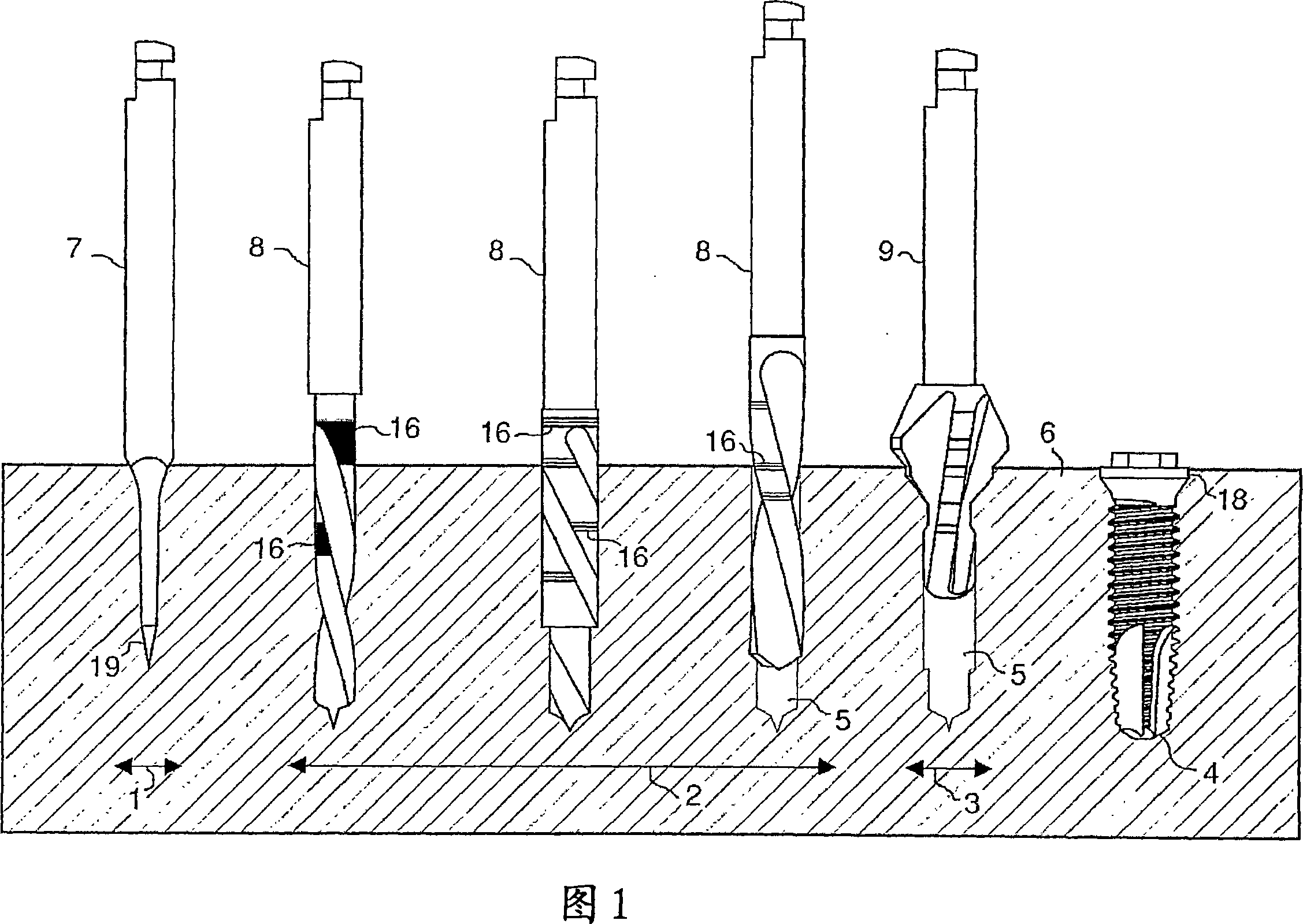

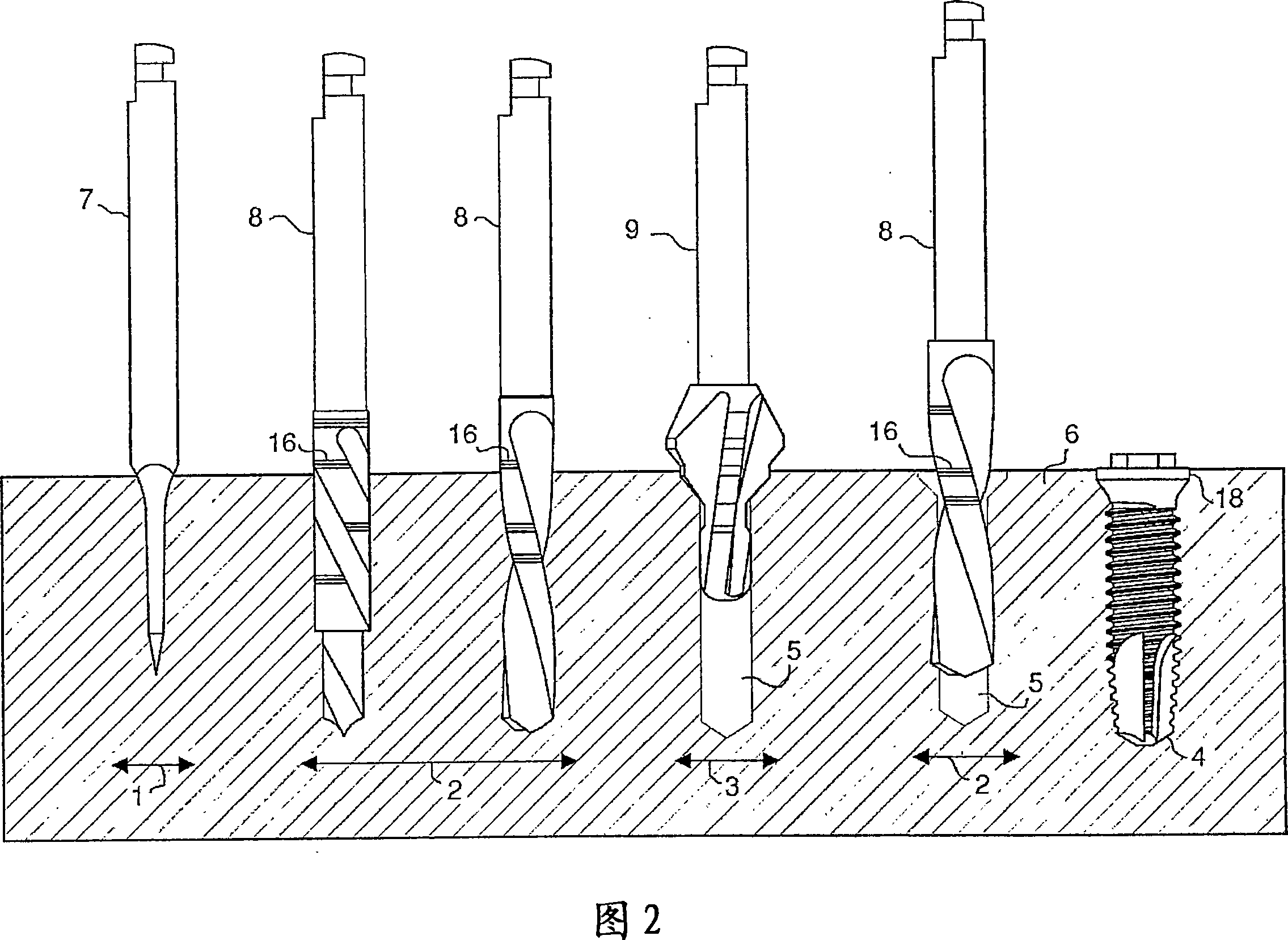

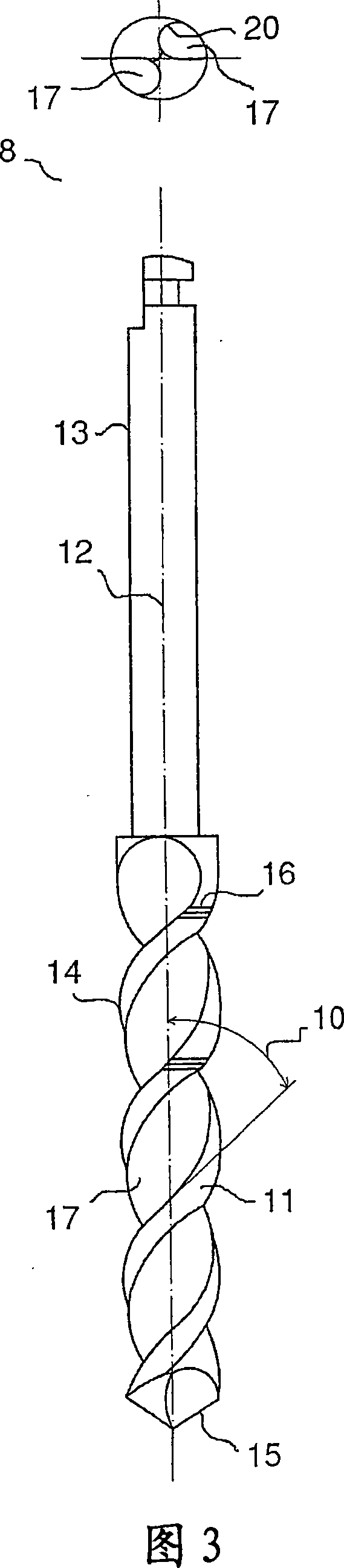

[0045] FIG. 1 shows an example of a low speed grinding method used to form cavities or pockets 5 in tissue 6 of a patient. In this particular case, the tissue is the maxilla and the cavity is formed to accommodate a dental implant 4 . In this method, as part of the initial stage 1, the cortical layer or the hardest outer part of the bone 6 is ground. An intermediate grinding stage 2 defining the cavity 5 follows. Finally, the method ends with a countersinking phase 3 of widening the cavity 5 to accommodate the head 18 of the dental implant 4 .

[0046] As noted in the description of the invention, the necessary tools are used at each grinding stage to produce the desired effect on the cavities and the like. In this respect, the starter burr 7 used during the initial phase 1 is characterized by a very sharp conical top 19 which enables the starter burr to start grinding the cavity. Furthermore, the countersinking drill 9 used during the countersinking phase 3 is shorter and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com