Ingot slow cool annealing process for low-carbon steel

A low-carbon alloy steel and annealing process technology, applied in the field of iron and steel metallurgy, can solve problems such as poor plasticity, reduce thermal stress and tissue stress, and avoid cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

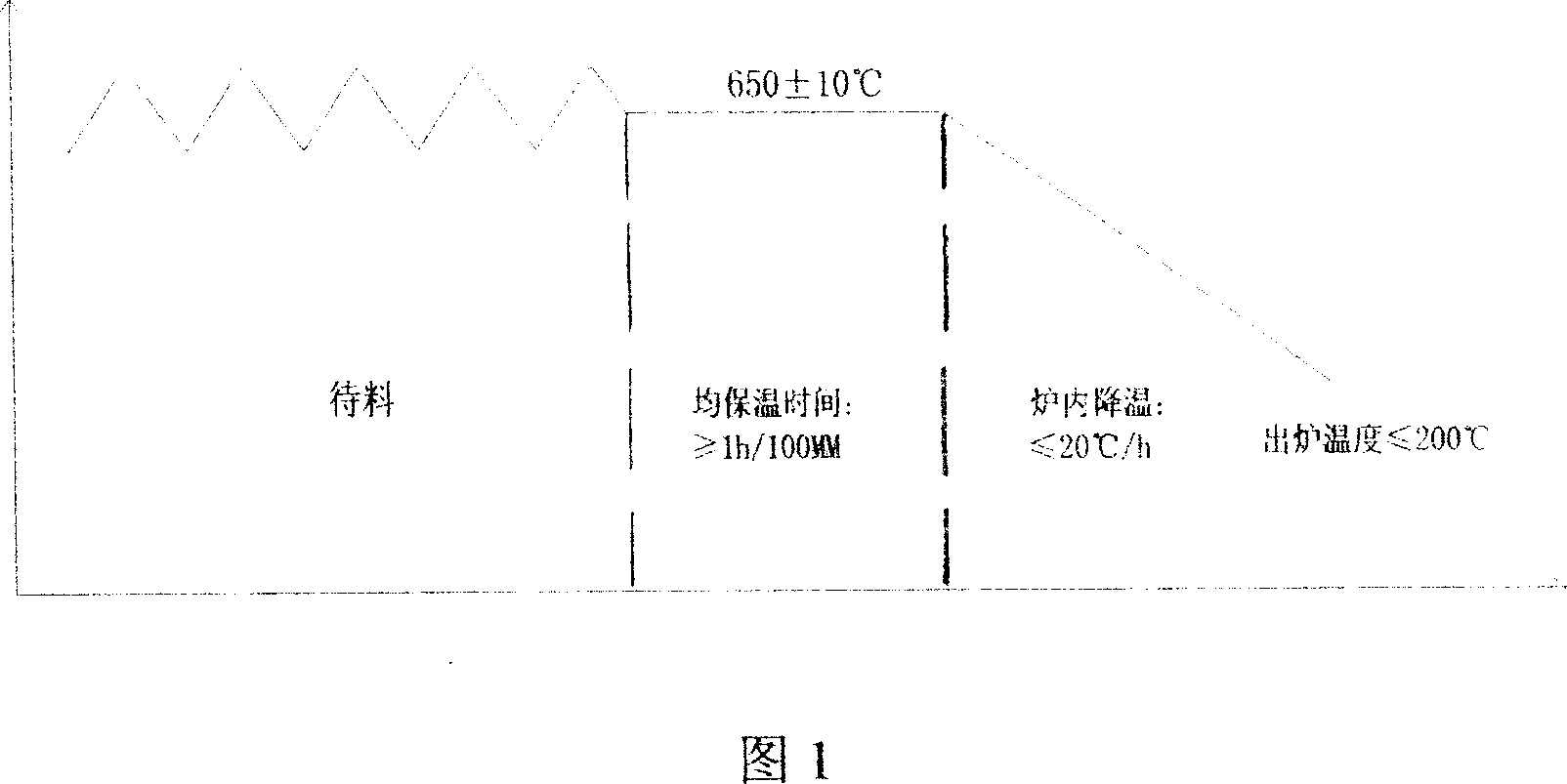

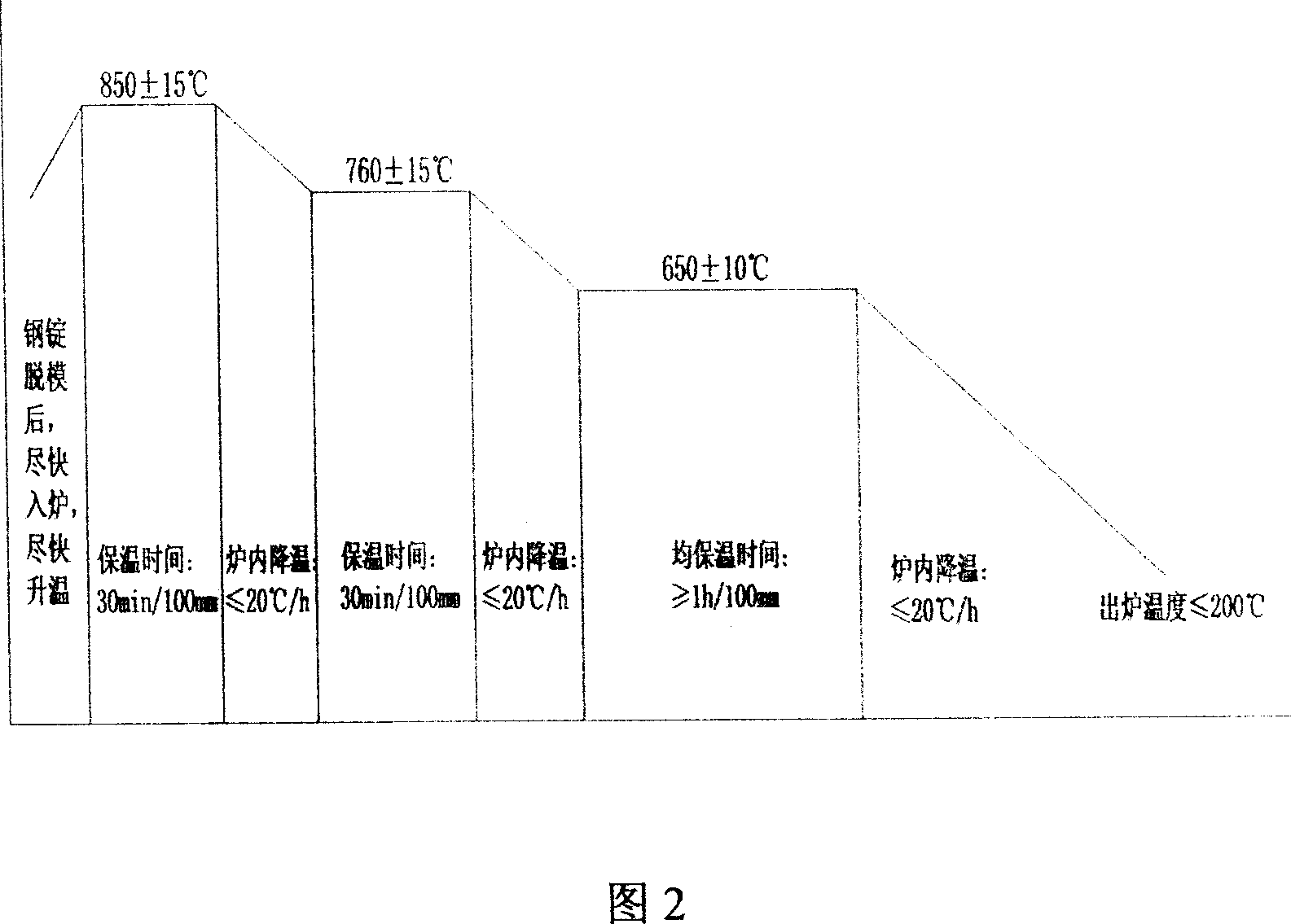

[0009] After the steel ingot of the present invention is removed from the mold, put it into the furnace as soon as possible and heat it up as soon as possible. When the temperature rises to 850±15°C, keep it warm for 30min / 100mm. 100mm, the temperature drop in the furnace is ≤20°C / h, when the temperature drops to 650±15°C, the average holding time: ≥1h / 100mm, the temperature drop in the furnace is ≤20°C / h, out of the furnace, and the temperature out of the furnace is ≤200°C.

[0010] The hundreds of steel ingots annealed by Inner Mongolia North Heavy Industry Group Co., Ltd. using the above-mentioned process have never cracked again. The steel grades involved are: 21CrMo10, 12Cr2MoG, 12Cr1MoVG, 17CrNiMo6, 20CrMnMo, 20CrNiMo, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com