Drum washing machine

A drum-type washing machine, drum technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of hindering drum rotation, abnormal rotation, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

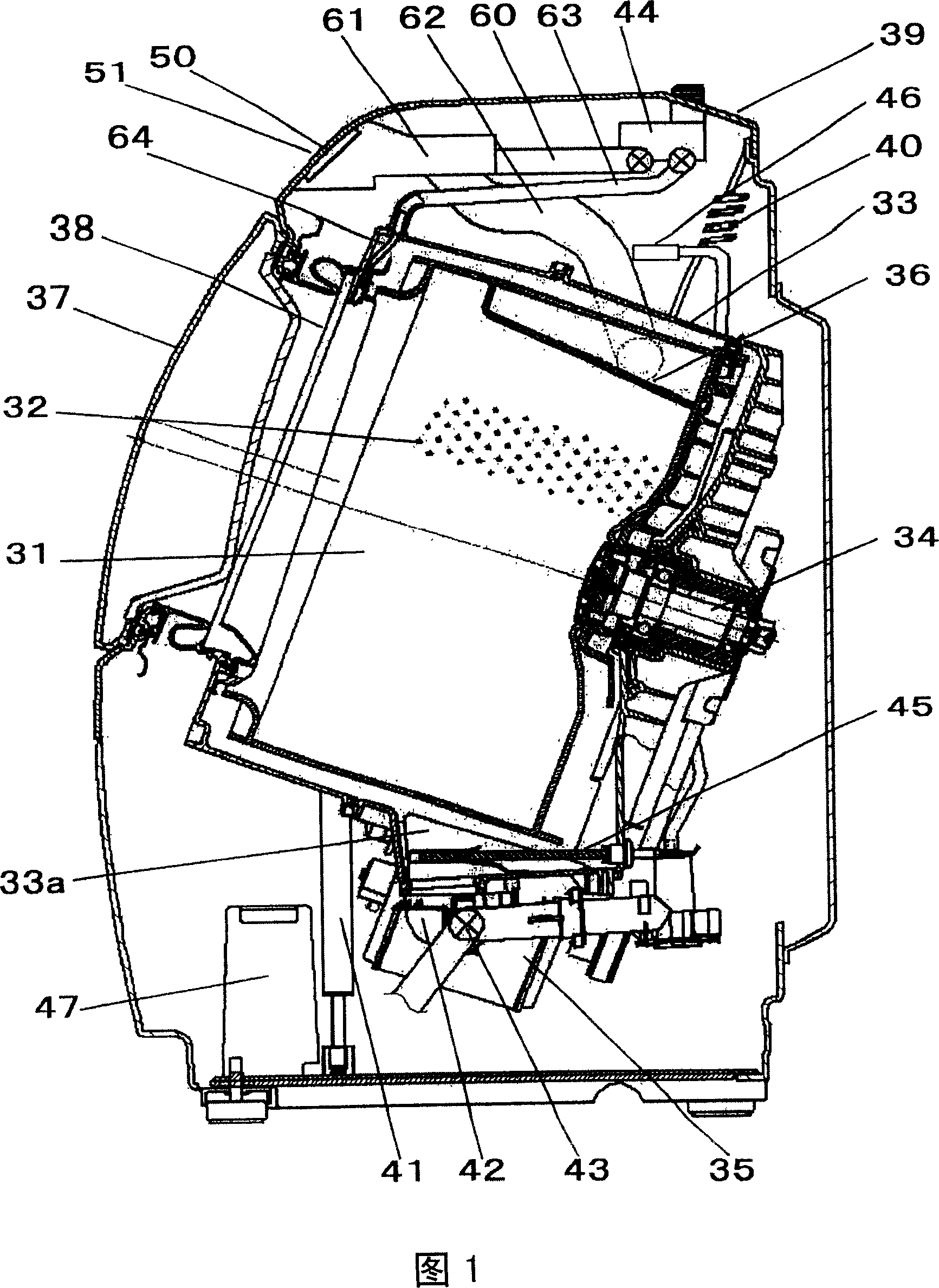

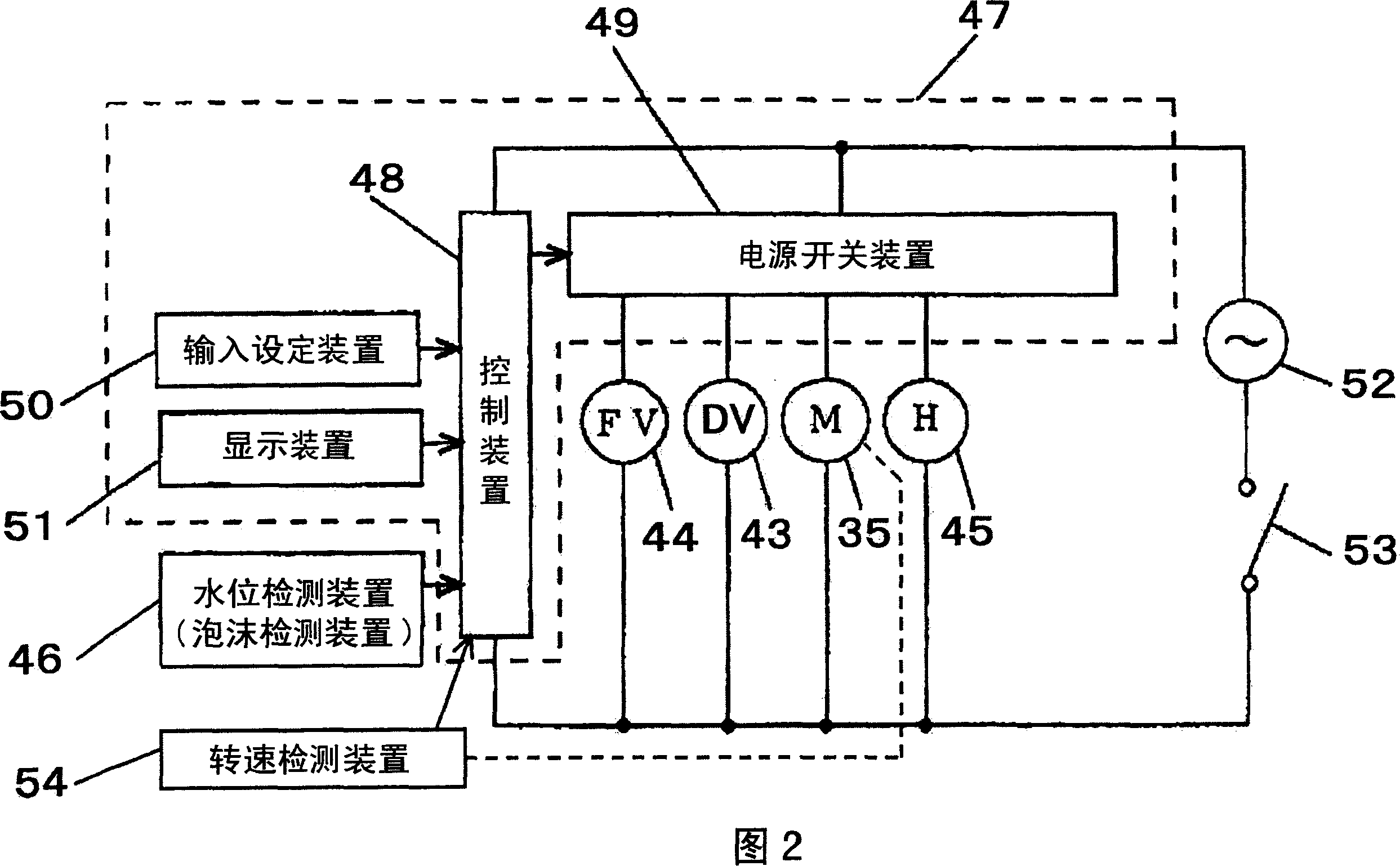

[0028] Fig. 1 is a side sectional view of a front-loading washing machine according to a first embodiment of the present invention, and Fig. 2 is a control circuit diagram of the partial modularization of the front-loading washing machine.

[0029] As shown in FIGS. 1 and 2 , the rotary drum 31 is formed in a bottomed cylindrical shape, has a plurality of water passage holes 32 on the entire outer peripheral surface, and is rotatably installed in a water tank 33 . The rotary drum 31 has a rotary shaft (rotation center shaft) 34 provided at its rotation center, and the axis direction of the rotary drum 31 is set to be inclined downward from the front side to the rear side. A motor 35 installed at the bottom of the water tank 33 is connected to the rotating shaft 34 to drive the rotating drum 31 to rotate forward and reverse. Several protruding plates 36 are provided on the inner wall of the rotating drum 31 to stir the clothes.

[0030] The opening provided on the upwardly inc...

Embodiment approach 2

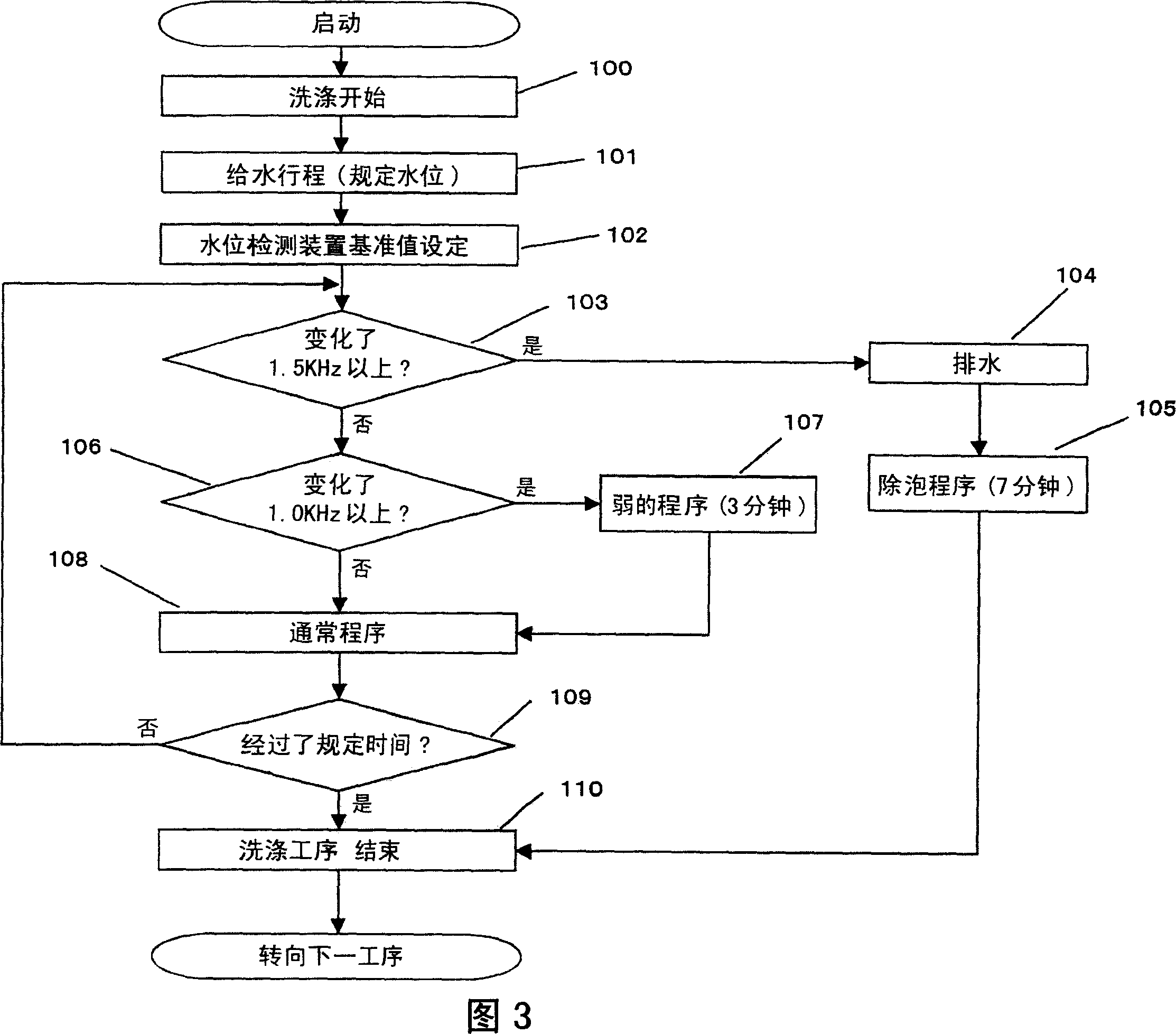

[0047] A second embodiment of the present invention will be described with reference to the control circuit diagram of FIG. 3 .

[0048] In step 103, when it is judged that the frequency change based on the standard water level is lower than 1.5 kHz, and the detergent foam is not abnormally generated, in the next step 106, when the frequency change based on the standard water level exceeds the second reference value, such as 1.0 kHz In the case where it is judged that the detergent foam is slightly more, it is judged that there is no need to run the defoaming process 105 when a large amount of detergent foam is generated, and after 3 minutes of running the program (step 107) that weakens the washing action, it returns to normal program (step 108).

[0049] The program (step 107) that has weakened the washing action mentioned here is that the rotating speed of the rotating drum 31 is slowed down such as about 10-20 r / min from the normal program such as 40-50r / min, or the rotati...

Embodiment approach 3

[0054] In this type of drum type washing machine, in the rinsing process, the washing water containing the detergent should be discharged after washing. In order to further remove the washing liquid contained in the clothes from the clothes, the rotating drum 31 should be rotated to use its centrifugal force to remove the washing liquid from the clothes. Centrifuge. In Embodiment 3, when a signal change is detected based on the water level detection of detergent foam and a large amount of detergent foam is generated (such as when the frequency change based on the standard water level exceeds 1.0 kHz), the above-mentioned rinsing process will not be performed. in the dehydration action. More specifically, it generally enters the normal rinsing process after washing. That is, the washing water containing the washing liquid is discharged, centrifuged (dehydrated), and thereafter, water supply, rinsing, draining, and centrifugation are performed a predetermined number of times. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com