Oil collecting casing connecting device

A technology of oil casing and connecting device, which is applied in the field of oil collecting type oil casing connecting device, can solve the problems of oil theft by criminals, crude oil pollution on the ground, affecting the accuracy of liquid level testing, etc., and achieves a convenient implementation and a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

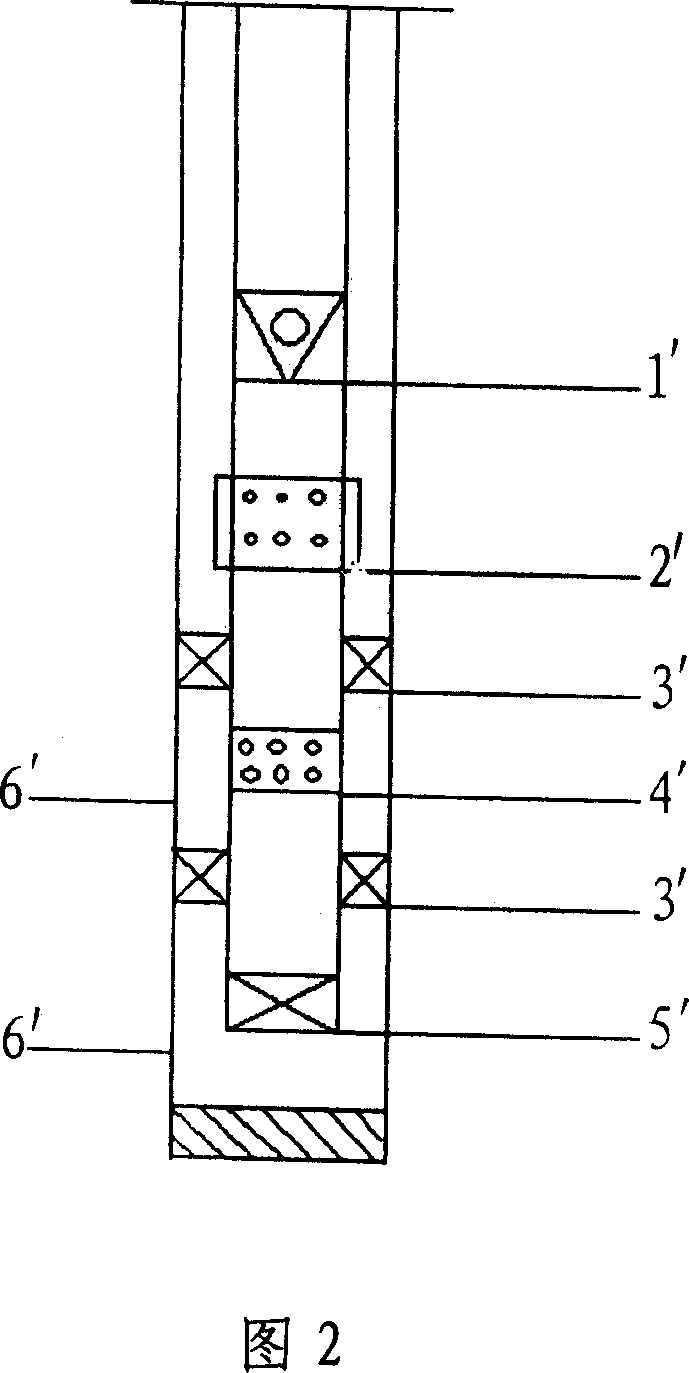

[0011] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

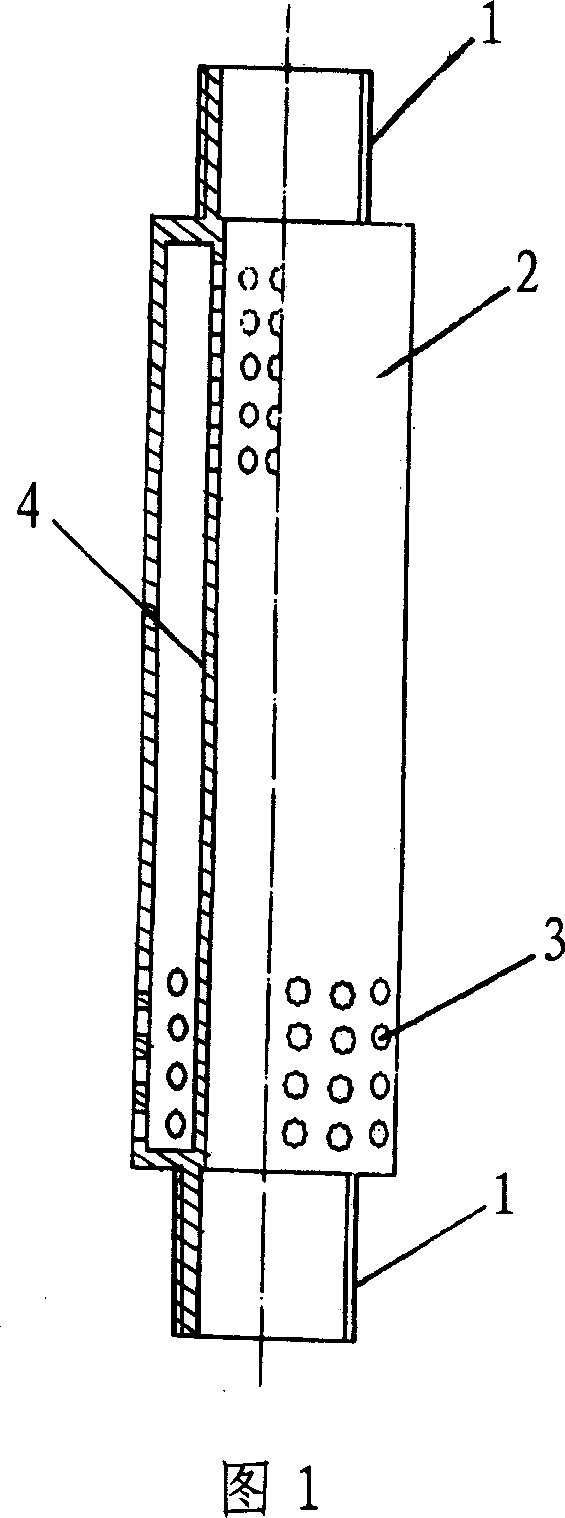

[0012] As shown in Figure 1, the present invention is made up of double-layer steel pipes, and it is characterized in that the diameter of the outer steel pipe 2 is slightly smaller than the diameter of the casing, the diameter of the inner steel pipe 4 is equal to or smaller than the diameter of the oil pipe, and the two ends of the inner steel pipe are provided with male threads 1, The outer steel pipe is welded between the two male threads of the inner steel pipe, and several holes 3 are arranged on the outer periphery of the upper part of the inner steel pipe, and several holes 3 are arranged on the outer periphery of the lower part of the outer steel pipe; The tubing is connected with a coupling.

[0013] There are many holes on the top of the inner steel pipe, and many holes on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com