Casting mold forming apparatus and metal mold unit for use therein

A technology of metal molds and casting molds, which is applied in the field of casting mold molding devices and metal mold devices, can solve the problems of fluid sand changes, fluid sand waste, and inability to ensure sufficient filling of fluid sand in mold cavities, and achieve shortening of hardening time, Fill more full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

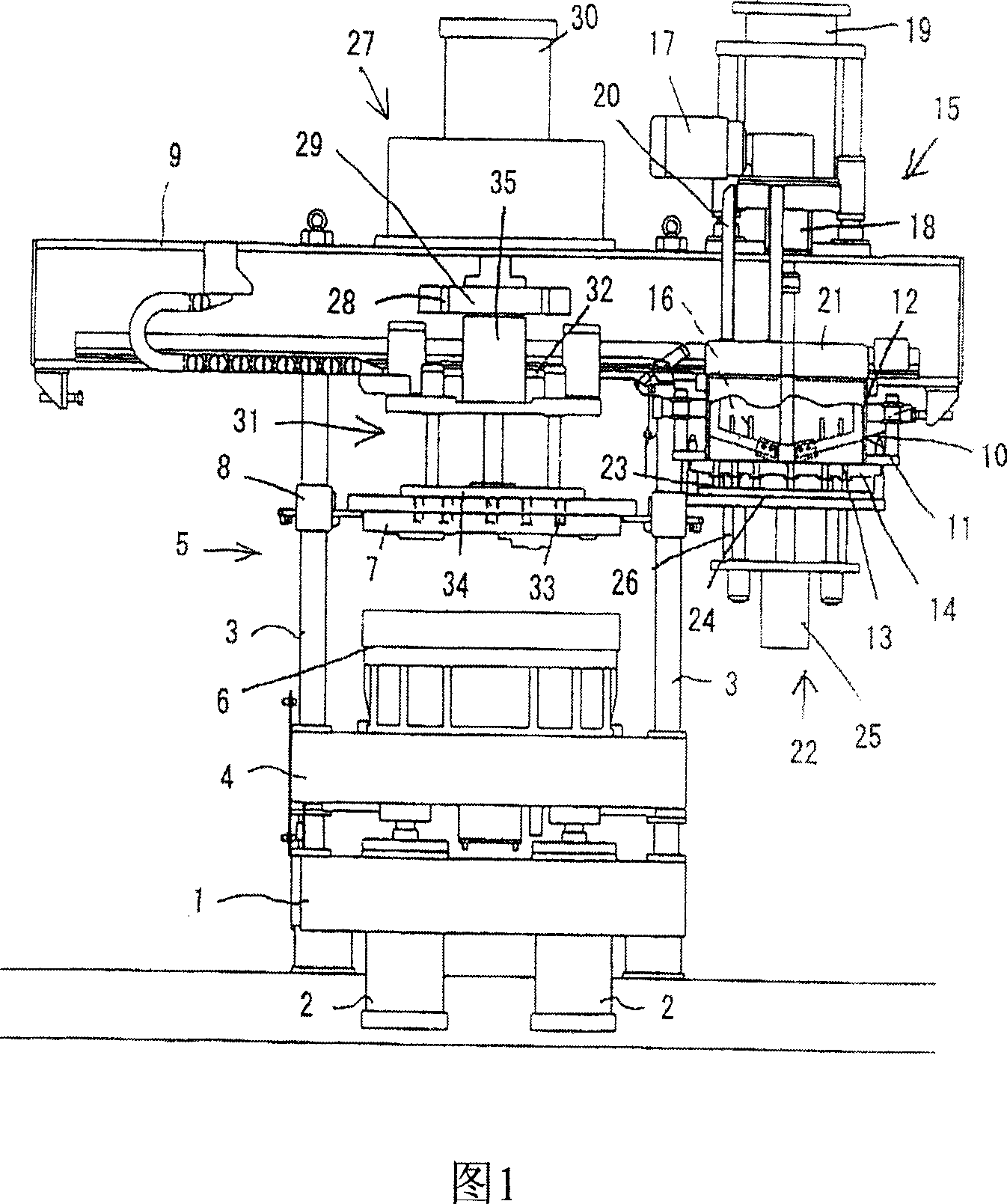

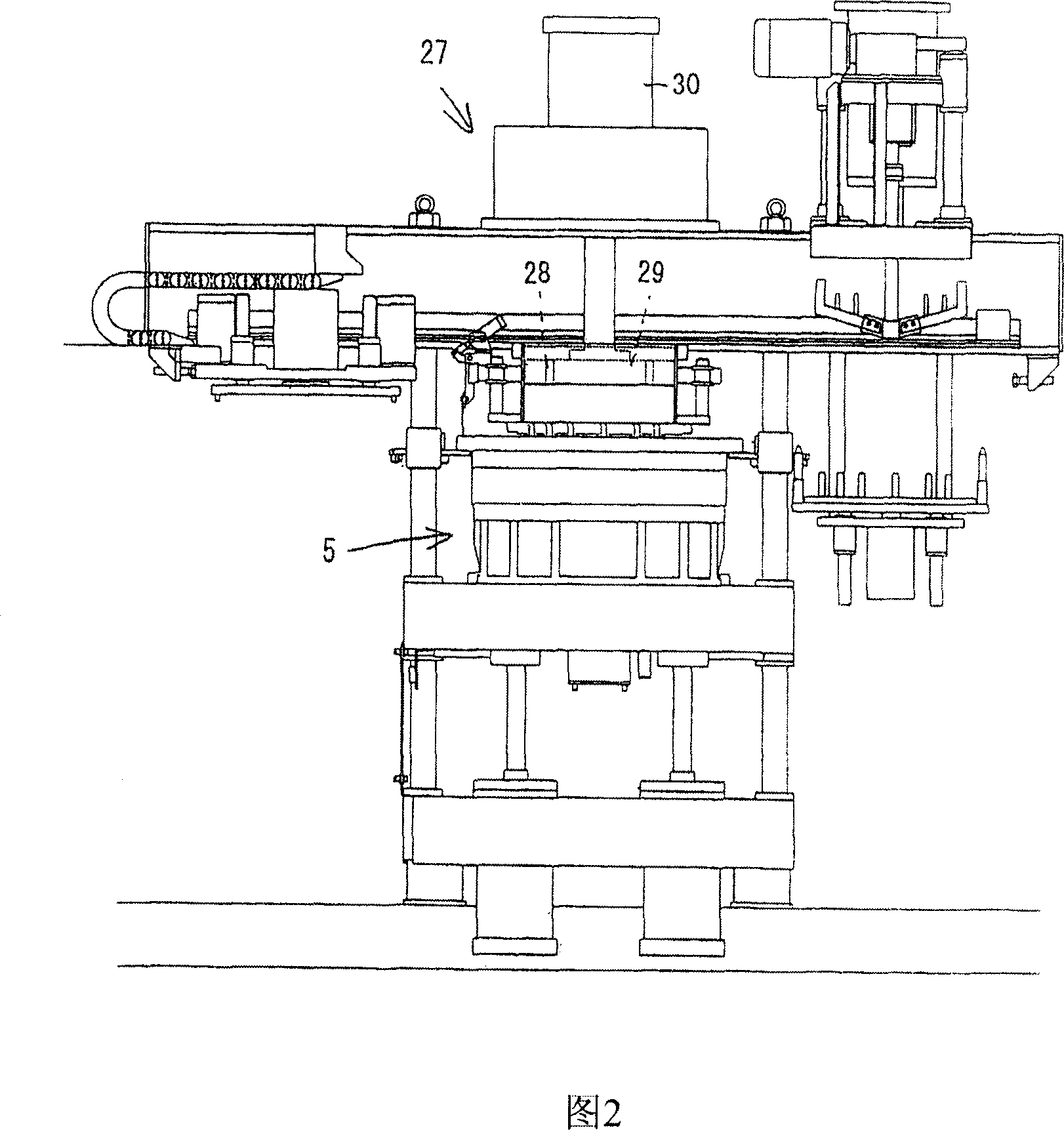

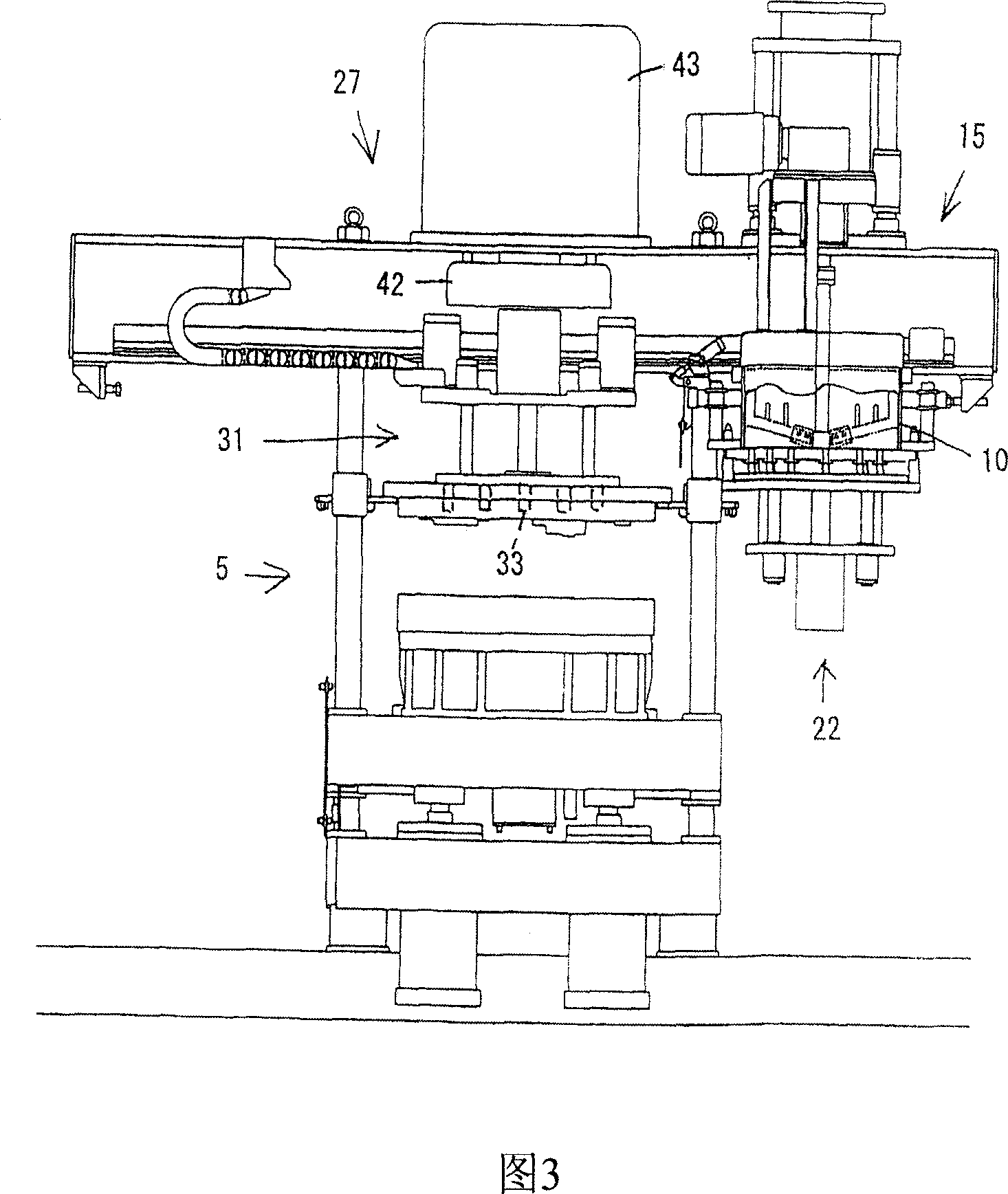

[0032] The best embodiment of the casting mold molding device suitable for the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] As shown in Fig. 1 and Fig. 2, in this casting mold molding device, two upward cylinders 2, 2 are arranged on the cube-shaped machine platform 1, and four guide rods are respectively arranged on the four corners of the above-mentioned machine platform 1 3, 3. A lifting frame 4 is erected between the upper ends of the piston rods of the above two cylinders 2, 2, the lifting frame 4 can slide and lift on the above-mentioned guide rods 3, 3, the upper surface of the lifting frame 4 is provided with a horizontally divided metal mold 5 in the lower metal mold 6 . The upper metal mold 7 that divides the metal mold 5 horizontally is provided directly above the lower metal mold 6, and the upper metal mold 7 is supported by four sets of support mechanisms 8, 8 that are arranged on the guide rod 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com