Method for preparing triangular nano palladium slice

A nano-palladium and nano-silver flake technology is applied in the field of preparation of triangular nano-palladium flakes, can solve problems such as unfavorable large-scale production, triangular nano-palladium flakes with multiple impurities, etc., and achieves the effects of low cost, non-oxidative denaturation, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

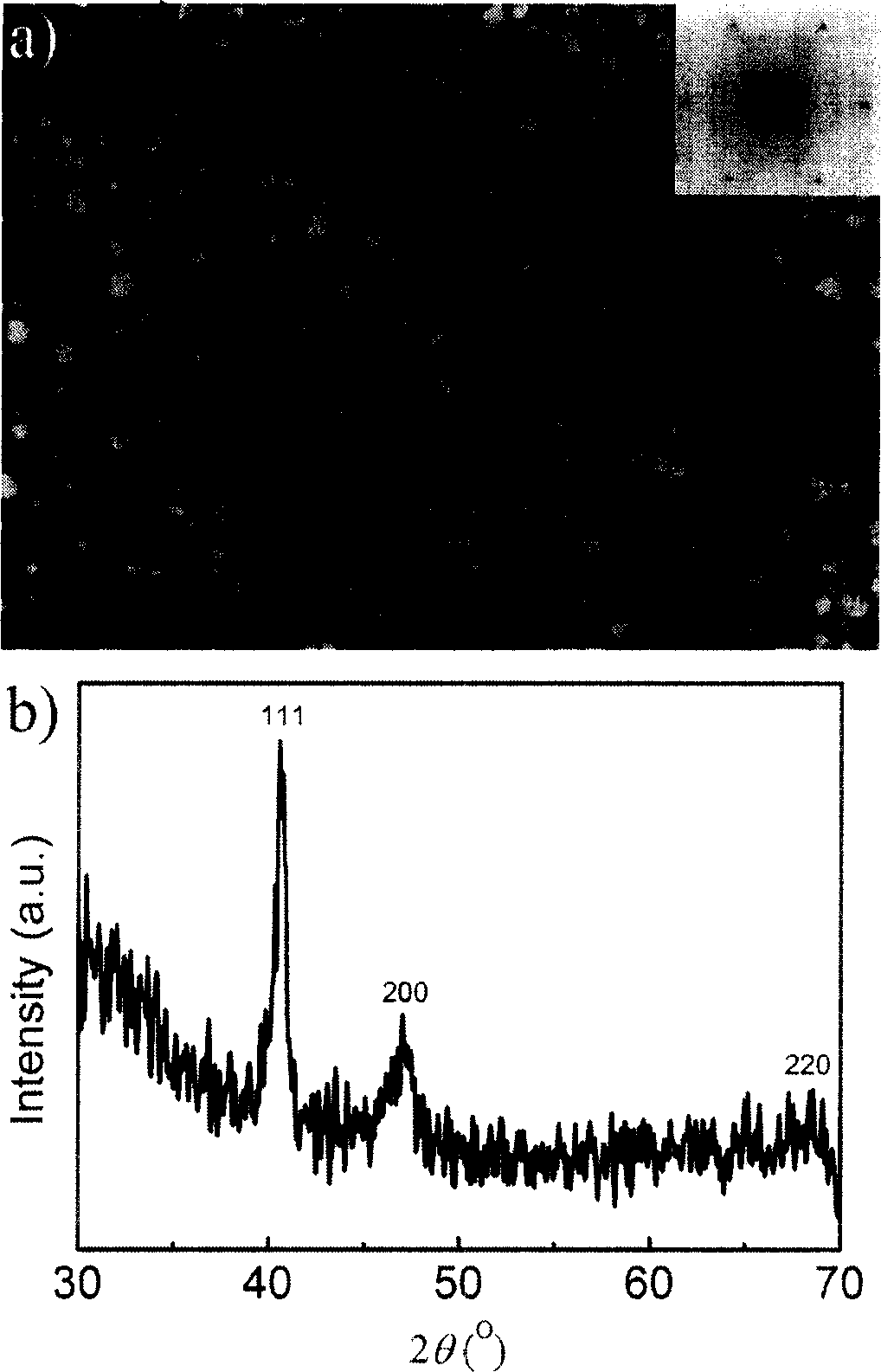

[0010] Embodiment 1: the preparation method of the triangular nano palladium sheet shown in figure a, its steps are:

[0011] (1) 60 milliliters of ternary solution systems containing water (6wt%) / PVP (K30, 2.3wt%) / n-amyl alcohol (91.7wt%) were prepared in a covered reaction vessel;

[0012] (2) 3 ml of PdCl 2 Saturated ethanol solution was added to the system under stirring, and after stirring for 5 minutes, it was placed in a constant temperature box for heat treatment at 95°C for 48 hours;

[0013] (3) centrifuging the heat-treated reaction solution to obtain high-purity triangular nano-palladium palladium flakes of required size.

Embodiment 2

[0014] Embodiment 2: the preparation method of triangular nano palladium plate, its steps are:

[0015] (1) 60 milliliters of ternary solution systems containing water (1wt%) / PVP (K30, 29wt%) / n-amyl alcohol (70wt%) are prepared in a covered reaction vessel;

[0016] (2) 3 ml of PdCl 2 Add the saturated ethanol solution into the system under stirring, continue stirring for 30 minutes, and then put it into a constant temperature box for heat treatment at 100°C for 30 hours;

[0017] (3) centrifuging the heat-treated reaction solution to obtain high-purity triangular nano-palladium palladium flakes of required size.

Embodiment 3

[0018] Embodiment 3: the preparation method of triangular nano palladium plate, its steps are:

[0019] (1) 60 milliliters of ternary solution systems containing water (7wt%) / PVP (K30, 10wt%) / n-amyl alcohol (83wt%) are prepared in a covered reaction vessel;

[0020] (2) 3 ml of PdCl 2 Add the saturated ethanol solution into the system under stirring, continue to stir for 20 minutes, and then put it into a constant temperature box for heat treatment at 80°C for 24 hours;

[0021] (3) centrifuging the heat-treated reaction solution to obtain high-purity triangular nano-palladium palladium flakes of required size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com