Method for preparing single dispersion triangular nano silver slice

A nano-silver flake, monodisperse technology, applied in the field of preparation of monodisperse triangular nano-silver flakes, can solve problems such as unfavorable large-scale production, high equipment requirements, and increase the difficulty of production operations, and achieve low cost, simple process, and equipment less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

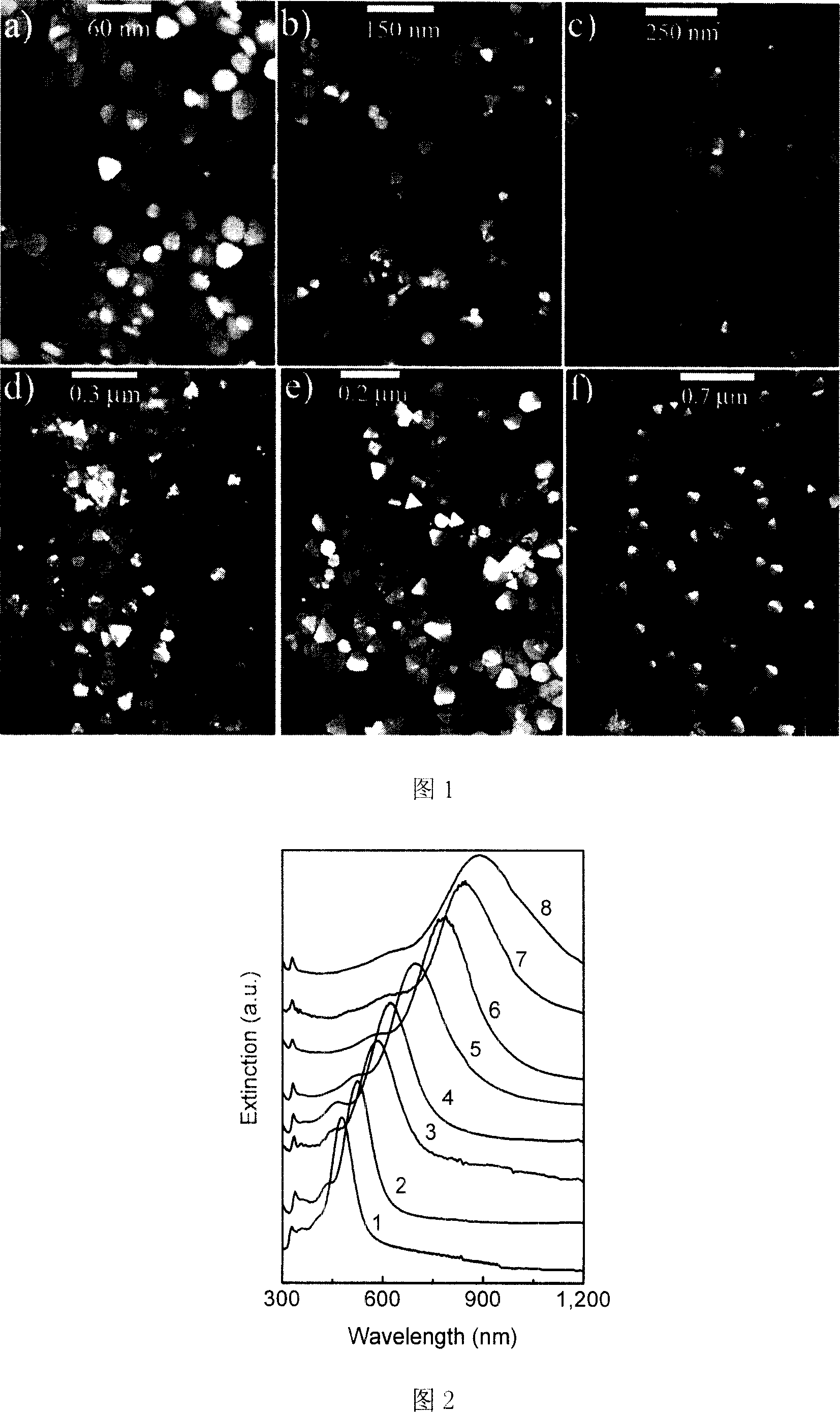

[0014] Embodiment 1: the preparation method of the triangular nano-silver sheet whose average side length is 92 ± 9nm (Fig. 1e), its steps are:

[0015] (1) 480 milliliters of ternary solution systems containing water (6wt%) / PVP (K30, 5wt%) / n-amyl alcohol (89wt%) are prepared in a covered reaction vessel;

[0016] (2) 24 ml AgNO 3 (0.6wt% of the ternary solution system) the ethanol solution was added to the system under stirring, and after continuing to stir for 5 minutes, put it into a constant temperature box for heat treatment at 95° C. for 48 hours;

[0017] (3) centrifuging the heat-treated reaction solution to obtain high-purity triangular silver nanosheets of required size.

Embodiment 2

[0018] Embodiment 2: the preparation method of the triangular nano-silver sheet whose average side length is 120 ± 11nm (Fig. 1f), its steps are:

[0019] (1) 480 milliliters of ternary solution systems containing (6wt%) / PVP (K30, 7wt%) / n-amyl alcohol (87wt%) are prepared in a covered reaction vessel;

[0020] (2) 24 ml AgNO 3 (0.6wt%) ethanol solution was added to the system under stirring, and after continuing to stir for 5 minutes, put it into an incubator for heat treatment at 95° C. for 48 hours;

[0021] (3) centrifuging the heat-treated reaction solution to obtain high-purity triangular silver nanosheets of required size.

Embodiment 3

[0022] Embodiment 3: the preparation method of triangular nano-silver sheet, its steps are:

[0023] (1) 480 milliliters of ternary solution systems containing water (1wt%) / PVP (K30, 29wt%) / n-amyl alcohol (70wt%) are prepared in a covered reaction vessel;

[0024] (2) 24 ml AgNO 3 (0.1wt%) ethanol solution was added into the system under stirring, and after continuing to stir for 15 minutes, put it into an incubator for heat treatment at 60° C. for 30 hours;

[0025] (3) centrifuging the heat-treated reaction solution to obtain high-purity triangular silver nanosheets of required size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com