Box-type section beam-column node structure and welding method

A beam-column joint and box-column technology, which is applied in building construction, construction, etc., can solve the problems of reducing material cost and production cost, difficult to guarantee, and difficult to achieve quality, and achieves reduction of material cost and production cost, integrity Strong, Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

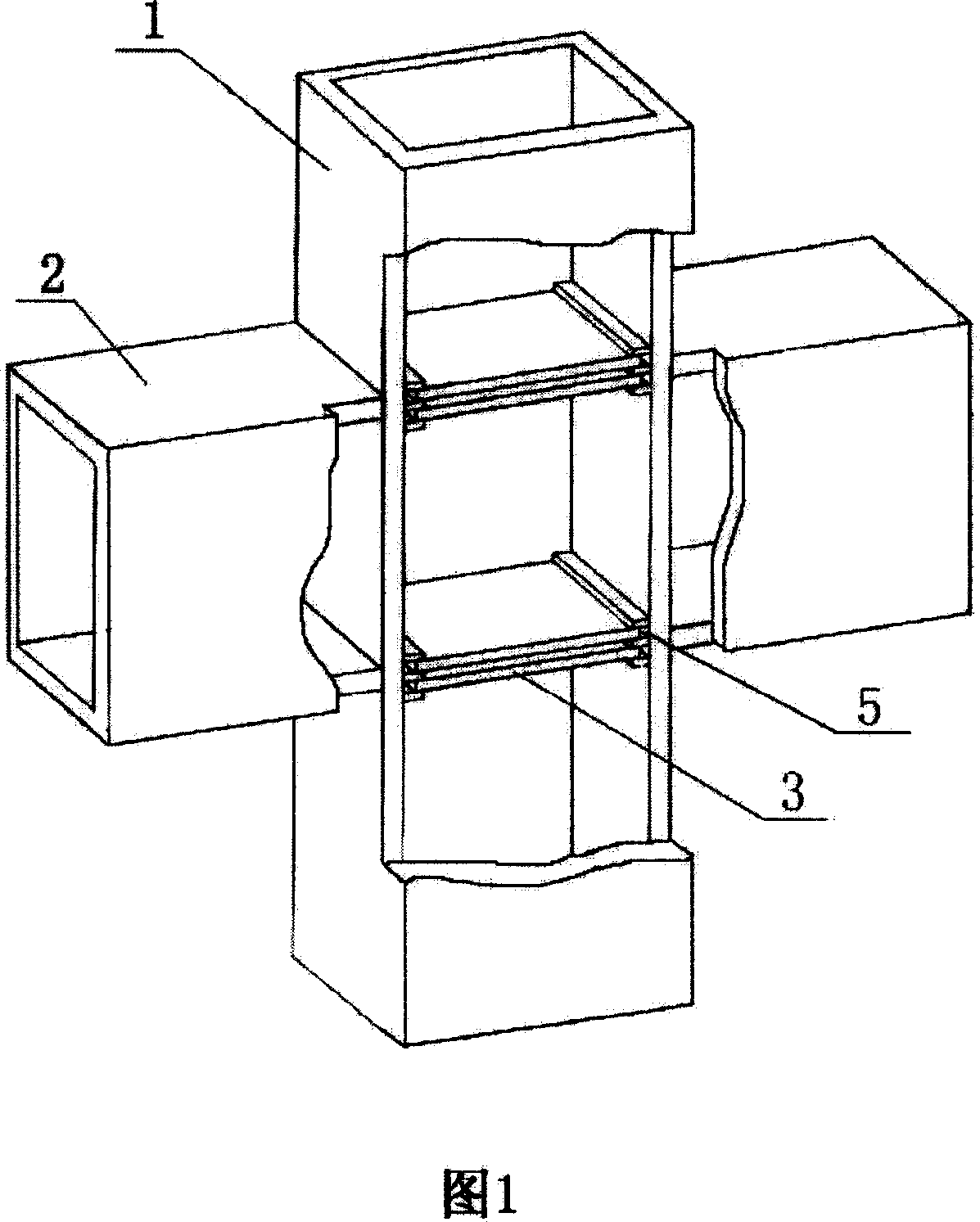

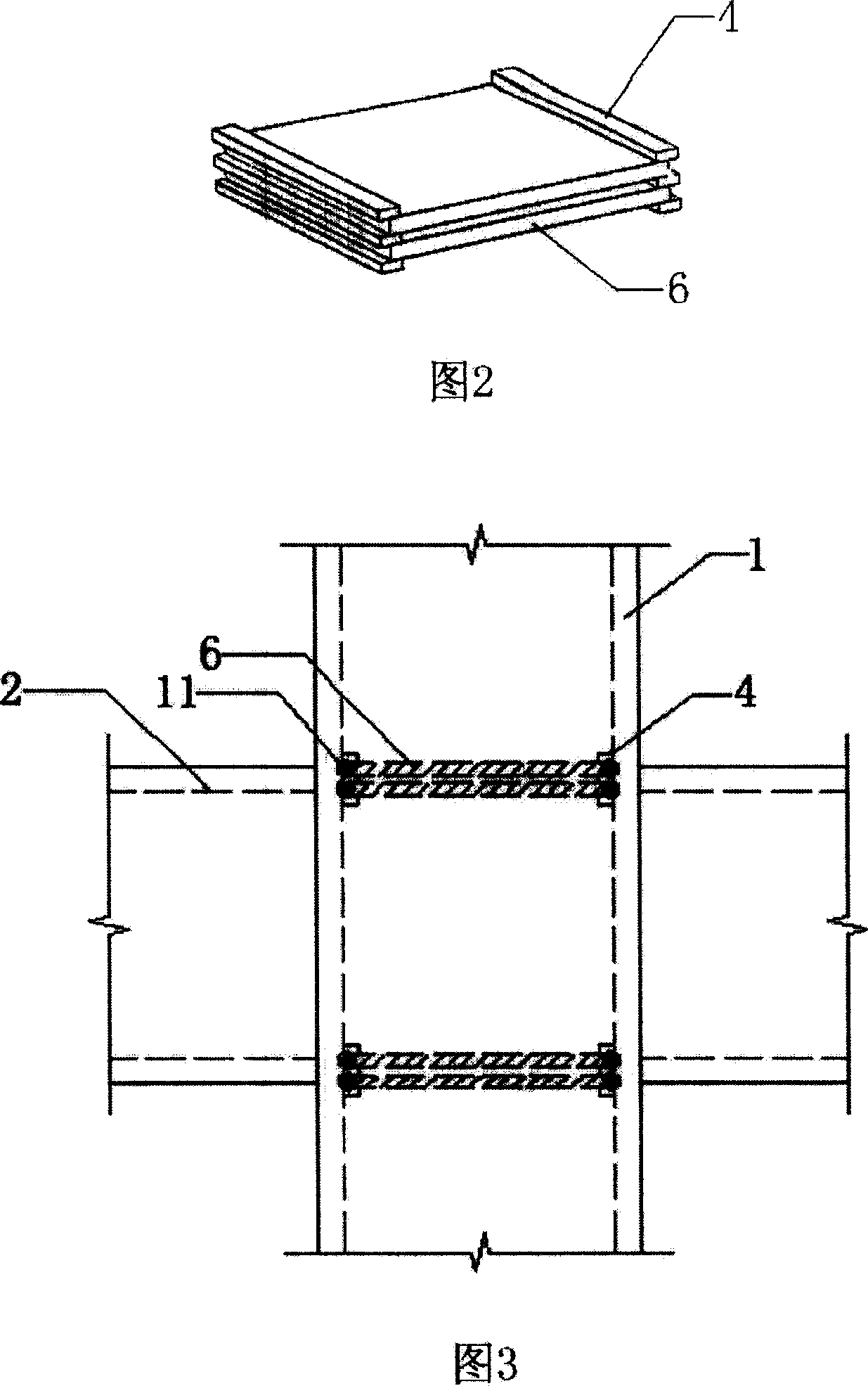

[0038] The first embodiment is shown in Figures 1 to 3. This box-section beam-column joint structure is formed by cross-welding box-shaped steel columns 1 and box-shaped steel beams 2, and a transverse stiffening inner partition 3 is welded in the box-shaped steel columns. The above-mentioned stiffening inner partition 3 is composed of two horizontal steel plates 6 with the same shape and size as the inner section of the box-shaped column and three steel spacers 4 sandwiched between the horizontal steel plates and located at both ends of the horizontal steel plates. The two ends of each horizontal steel plate are 5 away from the electroslag welding welding gap between the box-shaped steel wall plates, and the welding gap is welded by electroslag welding penetration, so that the stiffened inner partition 3 is welded to the box-shaped steel column 1 into one. The total thickness of the above two horizontal steel plates is greater than or equal to the thickness of the flange of t...

Embodiment 1

[0039] The concrete steps of implementing the welding of Example 1 are as follows:

[0040] Step 1: Two horizontal steel plates 6 with the same shape and size as the inner section of the box-shaped steel column 1 and three steel spacers 4 are interlaced and spot-welded to form a stiffened inner partition 3, and the space between each two steel spacers 4 and the horizontal A strip-shaped reserved electroslag welding gap 5 is formed between the ends of both sides of the steel plate 6 and the wall plate of the box-shaped steel column.

[0041] Step 2: Referring to Fig. 5, spot-weld the assembled stiffening inner partition 3 on the lower flange plate 8 of the box-shaped steel column at a predetermined position.

[0042] Step 3: Referring to Figure 6, weld the box-shaped steel column webs 9 on both sides of the box-shaped steel column to the lower flange plate 8 of the box-shaped steel column to form a box-shaped column with one side temporarily open, and then place the stiffened i...

Embodiment 2

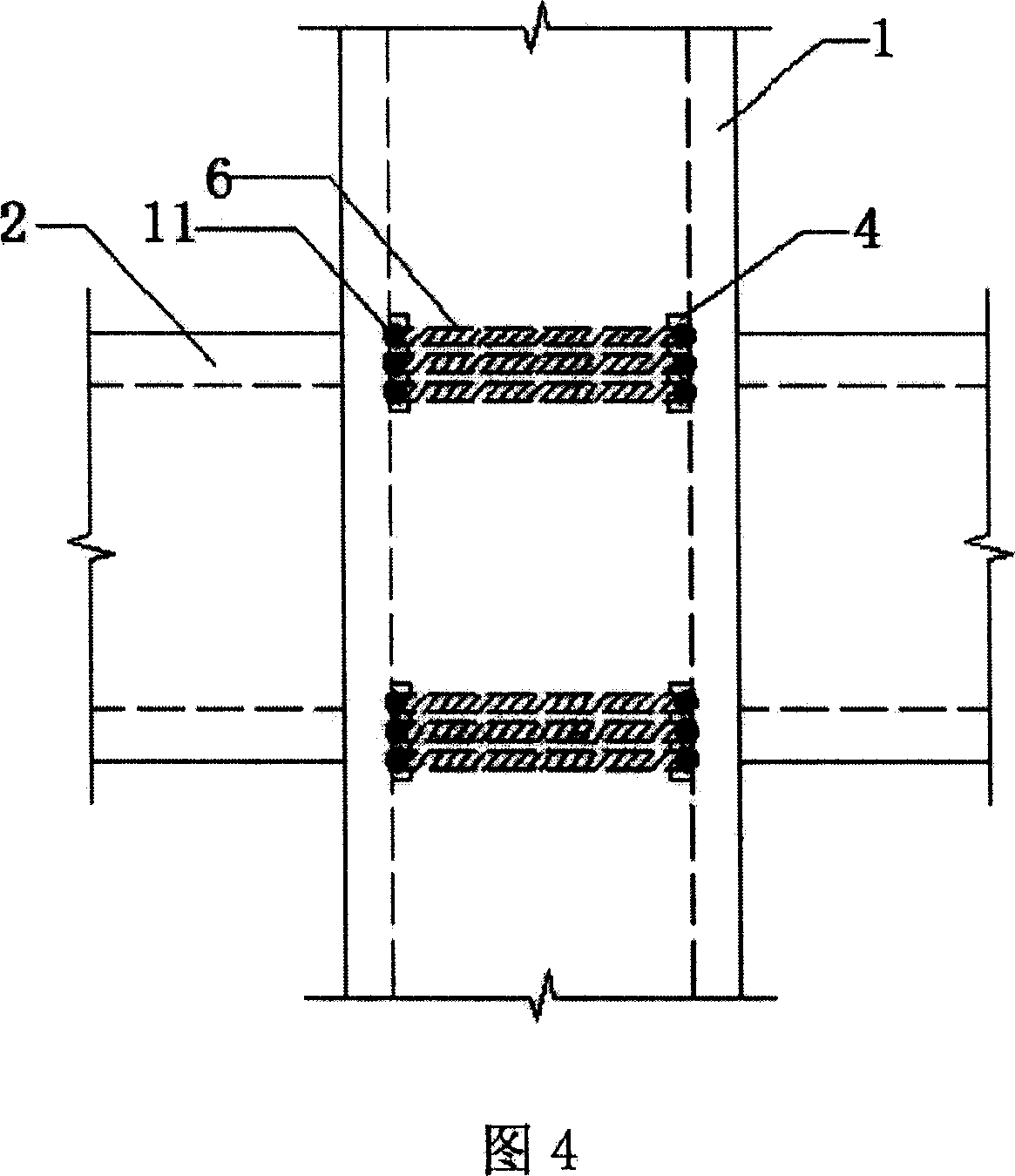

[0048] Implementation example two is shown in Fig. 4, the stiffening inner partition 3 is divided into three horizontal steel plates 6, and four steel pads 4 are used.

[0049] The welding concrete steps of implementation example two are as follows:

[0050] Step 1: Three horizontal steel plates 6 with the same internal section as the box-shaped steel column 1 and four steel pads 4 are interlaced and spot-welded to form a stiffened inner partition 3, and the space between each two steel pads 4 is connected to the horizontal steel plate 6 A strip-shaped reserved electroslag welding welding gap 5 is formed between the ends on both sides of the box-shaped column steel wall.

[0051] Step 2: spot-weld the assembled stiffening inner partition 3 on the lower flange plate 8 of the box-shaped steel column at a predetermined position.

[0052] Step 3: Weld the box-shaped steel column web 9 on both sides of the box-shaped steel column with the lower flange 8 of the box-shaped steel col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com