Edition-translation type numerical-control system and edition-translation and operation control method of same

A technology of numerical control system and controller, which is applied in the fields of computer and communication, electrical automation, and mechanical engineering, and can solve the problems of poor real-time performance, poor versatility, and weak openness ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

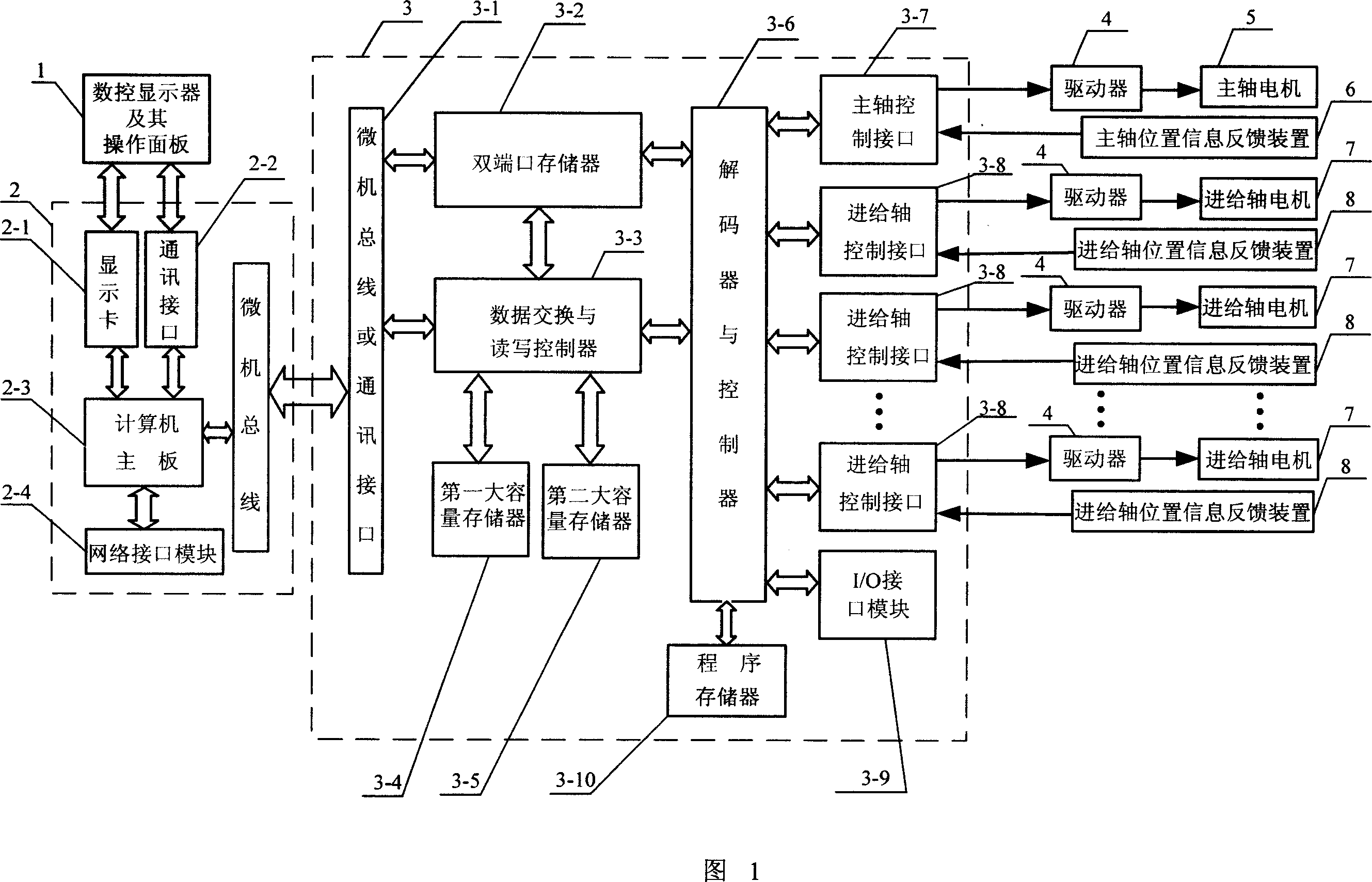

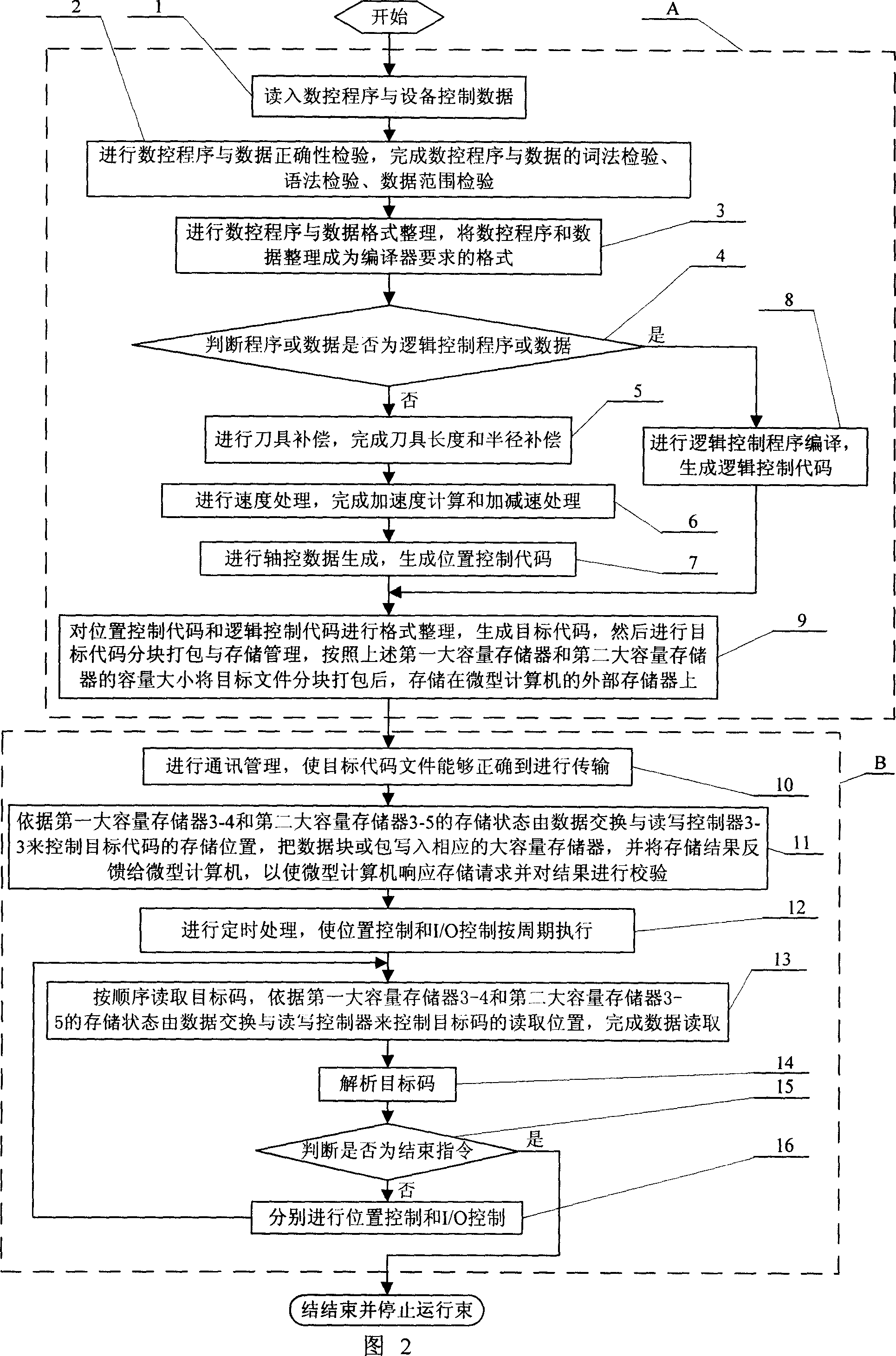

[0047] Specific embodiment 1: Referring to Fig. 1 to 3, the compiled numerical control system of this specific embodiment consists of a numerical control display and its operation panel 1, a microcomputer 2, a data transmission storage controller 3, a plurality of drivers 4, a spindle motor 5, a spindle The position information feedback device 6, a plurality of feed shaft motors 7 and a plurality of feed shaft position information feedback devices 8 are composed; the microcomputer 2 includes a display card 2-1, a communication interface 2-2 and a computer motherboard 2-3, The data transmission end of the numerical control display is connected to a data transmission end of the display card 2-1 through the data bus, and the other data transmission end of the display card 2-1 is connected to the bus of the computer main board 2-3 through the microcomputer bus. The communication control end of the operation panel is connected to the communication interface 2-2 through the communica...

specific Embodiment approach 2

[0056] Specific embodiment two: referring to Fig. 1, the difference between this specific embodiment and specific embodiment one is: described microcomputer 2 comprises network interface module 2-4, and described network interface module 2-4 communicates with computer main board through microcomputer bus 2-3 connected. In this specific embodiment, the network interface module 2-4 is connected to other numerical control systems or computer systems to realize the networking of the numerical control system. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

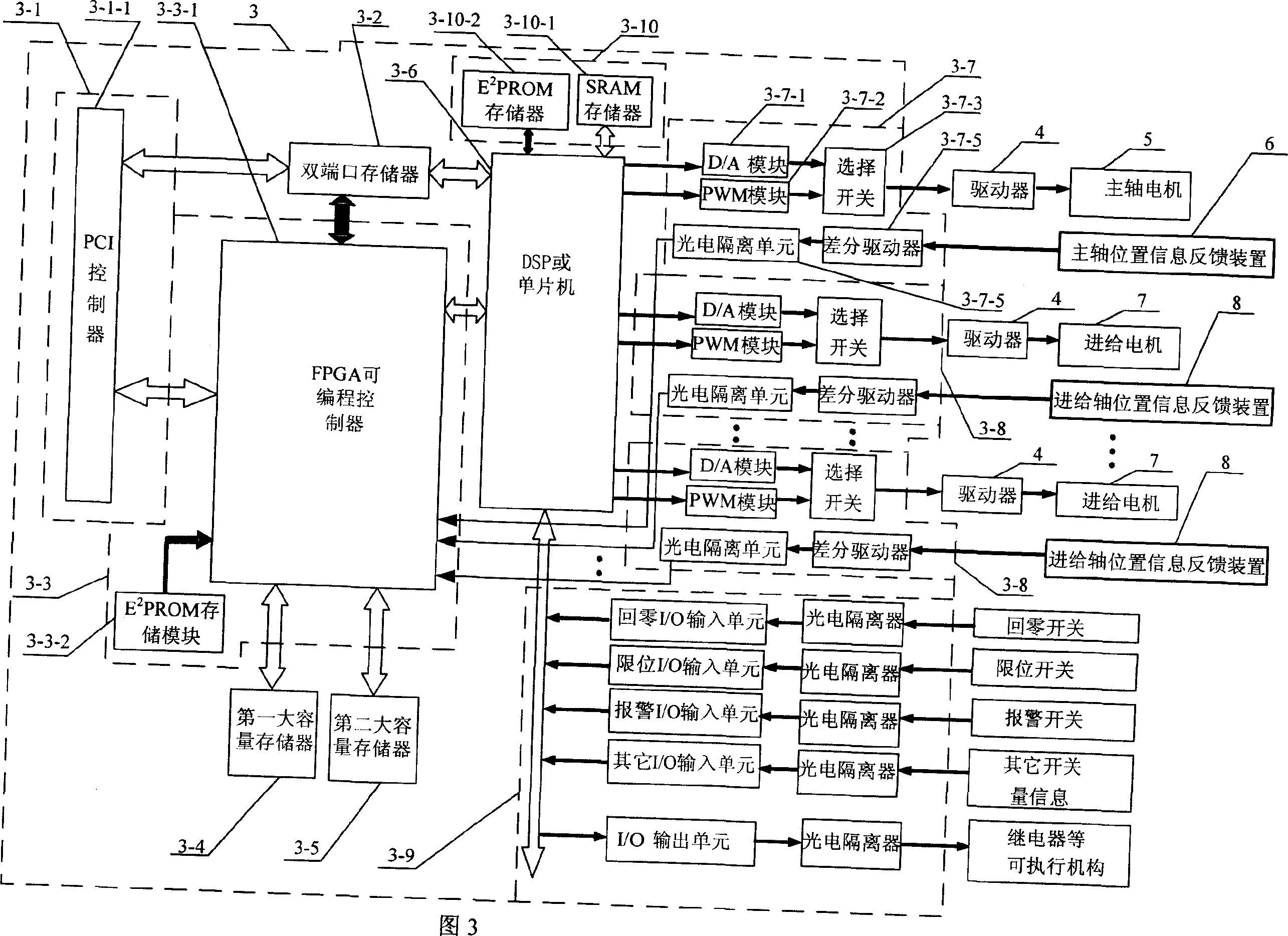

[0057] Specific embodiment three: referring to Fig. 3 and Fig. 4, the difference between this specific embodiment and specific embodiment one or two is: described FPGA programmable controller 3-3-1 can be read and written by PCI decoder 101, PCI Read and write address generator 102, PCI and DSP read and write selection command generator 103, DSP read and write decoder 105, DSP read and write address generator 104, DSP read and write encoding register 106, PCI and DSP read and write switching control state machine 112. Motor speed calculator 107, first SDRAM controller instruction generation state machine 115, second SDRAM controller instruction generation state machine 113, first SDRAM data channel 114, second SDRAM data channel 118, first SDRAM read and write timing Control state machine 116, second SDRAM read and write timing control state machine 117, encoder signal counter 108, encoder signal direction detector 109, encoder signal quadrupler 110 and encoder signal digital f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com