Method for setting up mould of cracking reaction in ethylene cracking furance burning and reacting tube

A cracking reaction and ethylene cracking technology, which is used in hydrocarbon cracking to produce hydrocarbons, special data processing applications, instruments, etc. It can solve the problems of complex elementary reaction model, large amount of calculation, and narrow scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

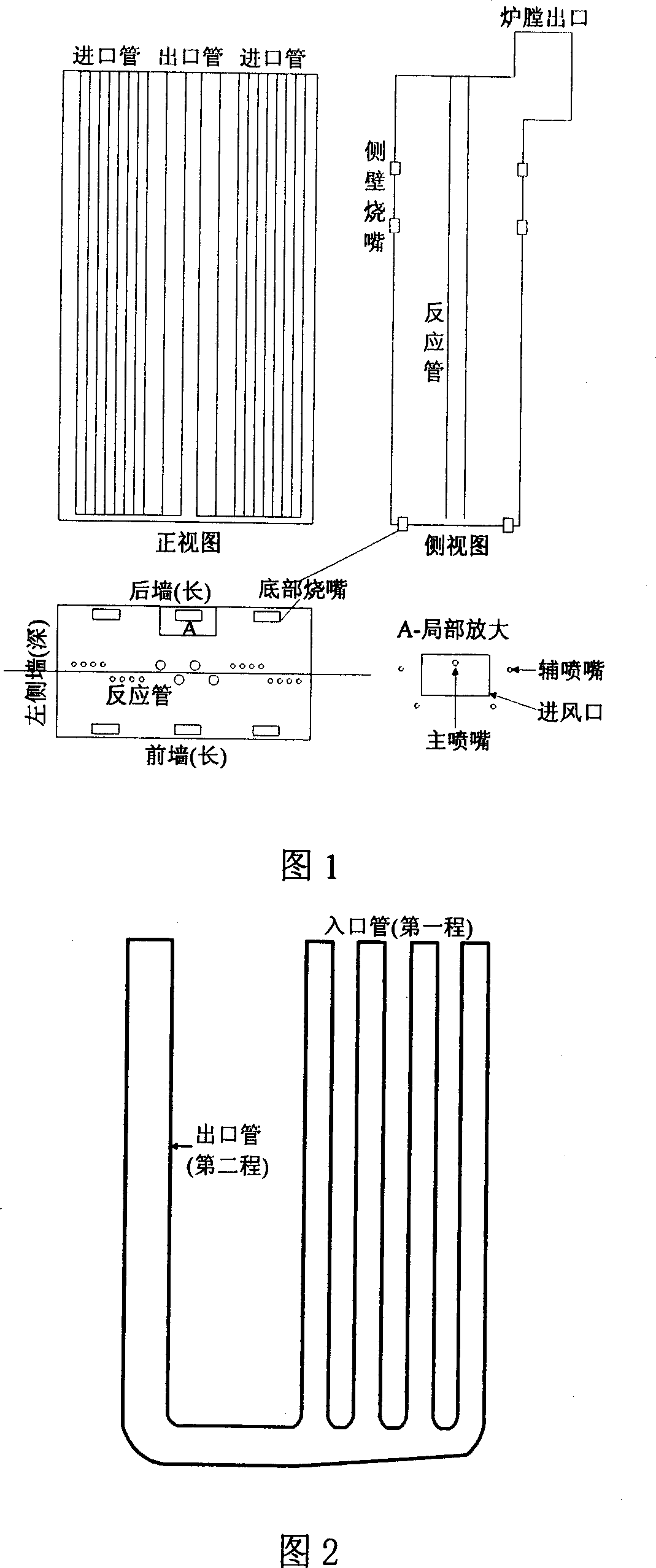

[0088] Below in conjunction with naphtha cracking furnace example the present invention will be further described:

[0089] The actual production history data of an olefin plant of a petrochemical company is used to verify the effectiveness of the model.

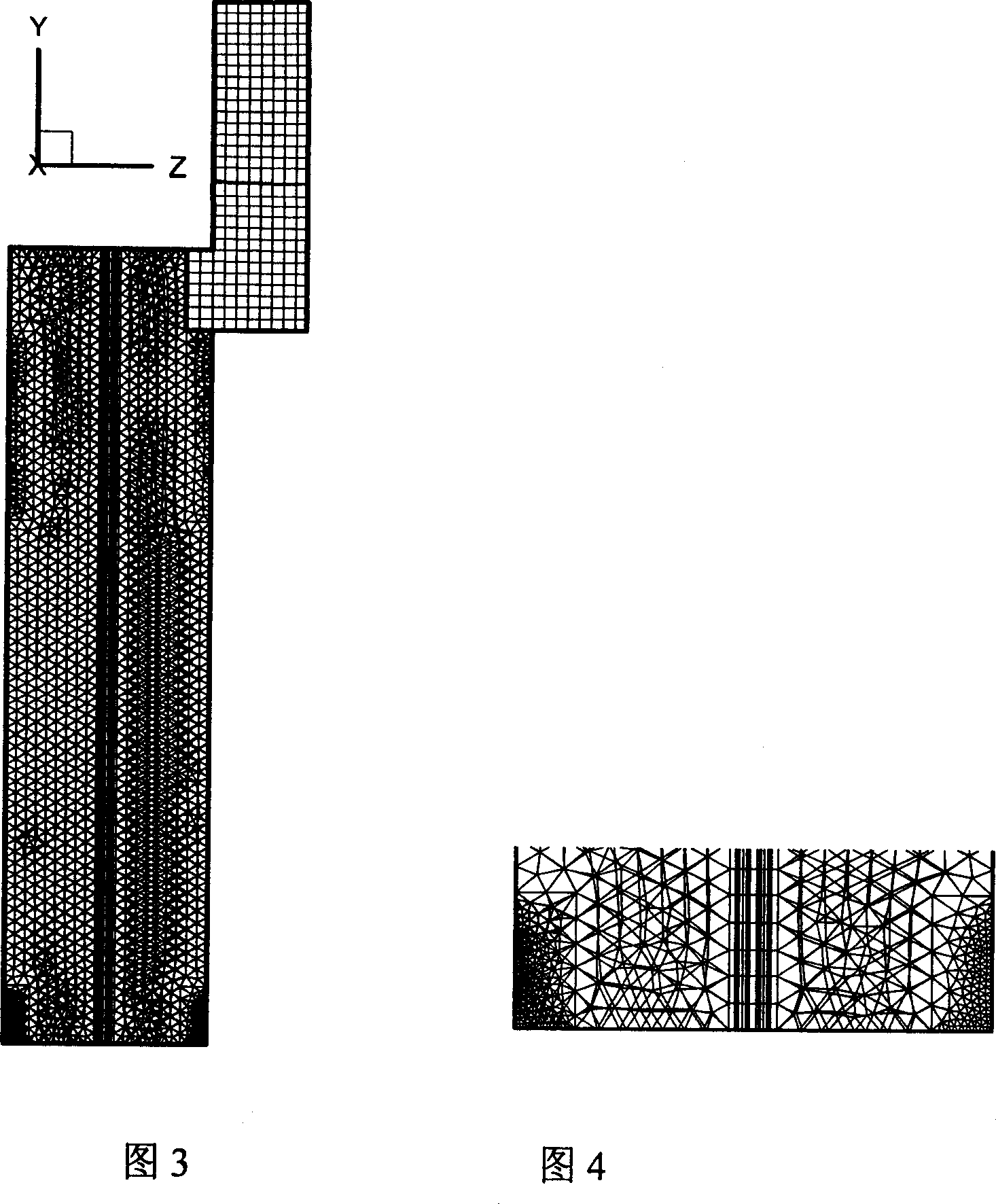

[0090] The model is divided into two systems of furnace combustion and reaction tube to be calculated separately, and the two systems are coupled by thermal boundary conditions. Based on the analysis results of gas components, a PDF file of non-premixed combustion is established for thermochemical calculation, and the PDF file of thermochemical calculation results is imported into the furnace model for calculation of gas combustion and heat transfer. The coupling calculation of the furnace combustion and the pyrolysis reaction in the reaction tube refers to the coupling of boundary conditions, that is, the heat flux (distribution along the tube length) of the reaction tube obtained by the furnace combustion is used (programm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com