Method for preparing ultrathin silicon nitride/silicon dioxide laminated gate medium

A technology of silicon dioxide and stacked gates, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

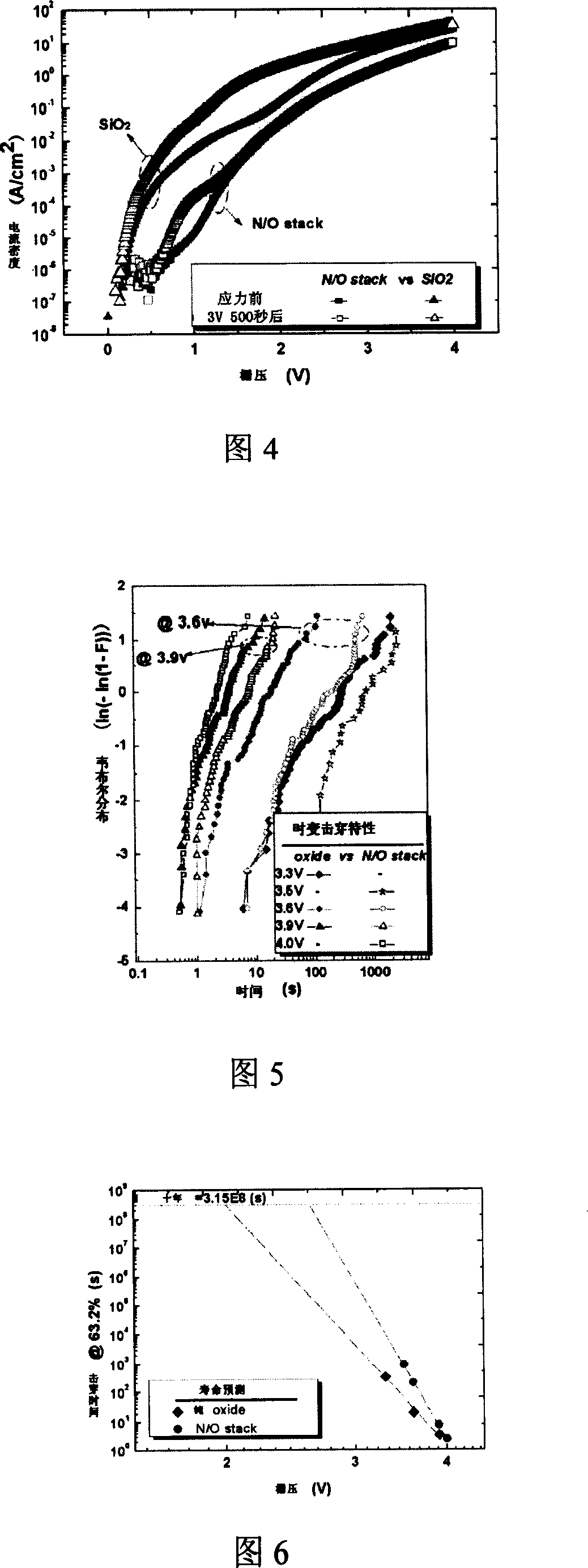

Method used

Image

Examples

Embodiment

[0033] 1. Monolayer growth:

[0034] 1) Ultra-thin SiO 2 Preparation of gate dielectric:

[0035] Note 14 N + , re-oxidation method to reduce the oxidation rate; at the same time reduce the oxidation temperature and reduce the oxidation time to prepare an ultra-thin oxygen pad layer. The oxidation conditions are as follows:

[0036] .Note 14 N + : Energy is 20kev, dose: 3E14cm -2 ;

[0037] Oxidation temperature: 690°C;

[0038] Oxidation time: 2s;

[0039] N 2 :O 2 =25:1.

[0040] 2. Preparation of ultra-thin Si by LPCVD method 3 N 4 membrane;

[0041] Using TEMPRESS 280 equipment to prepare ultra-thin Si 3 N 4 Film, the equipment has good process repeatability, and the deposited film has good uniformity. The reaction source gas adopts: SiH 2 Cl 2 and NH 3 , the reaction equation is as follows:

[0042] 3SiH 2 Cl 2 (gas)+4NH 3 (gas) → Si 3 N 4 (solid)+6H 2 (gas)

[0043] In order to prepare ultra-thin Si 3 N 4 film, to improve the controllabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com