Method for preparing lithium secondary cell electrode containing nano additive

A lithium secondary battery and nano-additive technology, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of increasing the preparation cost of electrode materials and complex preparation process of electrode active materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 01

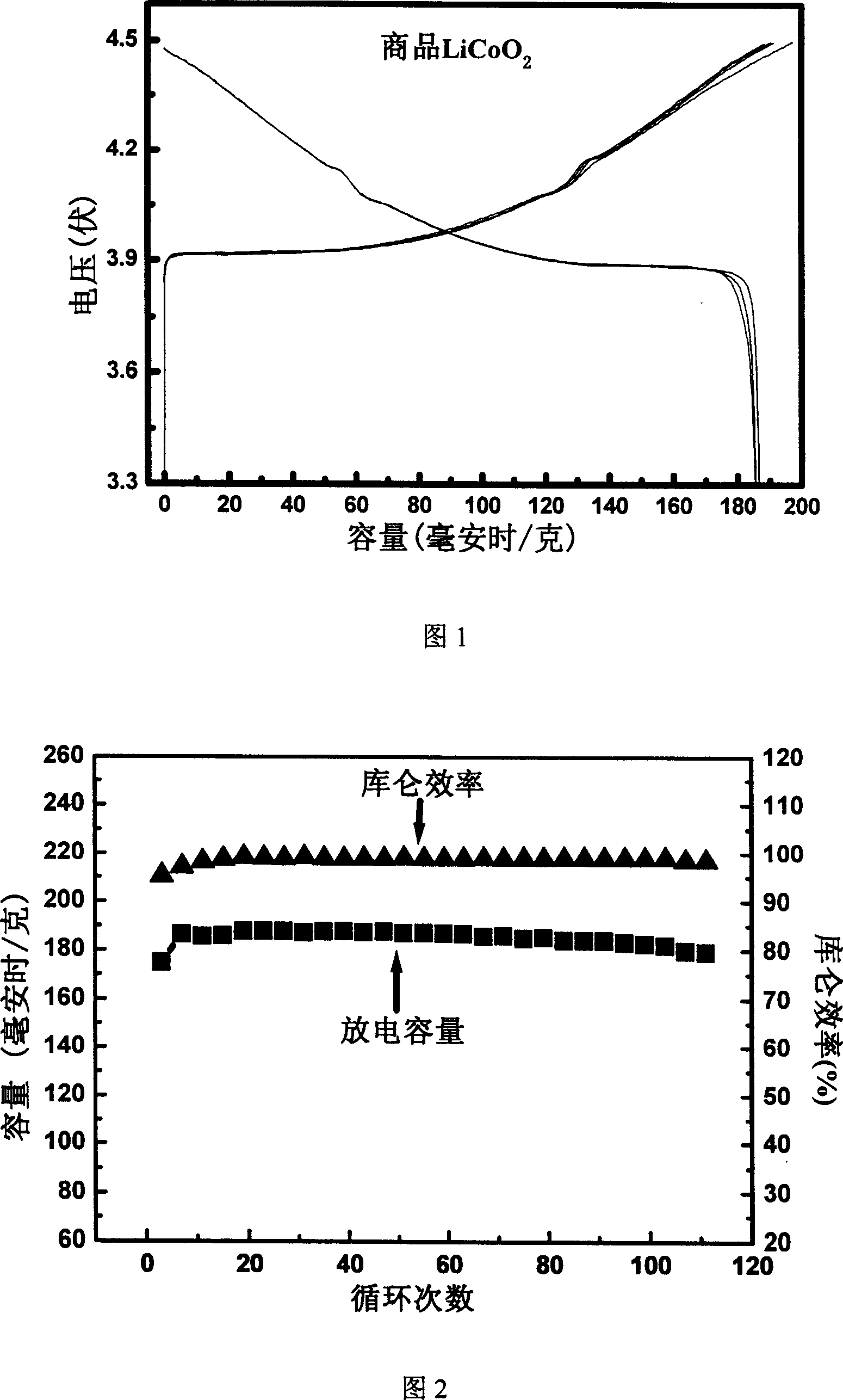

[0069] According to the first method, a positive electrode of a lithium secondary battery containing a metal Al additive is prepared. Metal Al particles with an average particle size of 1500 nm, commercial positive electrode active material LiCoO with an average particle size of 4500 nm 2 and binder polyvinylidene fluoride (PVdF) mixed evenly. The amount of Al powder added accounted for 10% of the total weight of the positive electrode material -3 times, the binder PVdF accounts for 0.05 of the total weight of the positive electrode material, and the positive electrode active material LiCoO2 It accounts for 0.949 times of the total weight of the positive electrode material.

[0070] Add the solvent N-methylpyrrolidone (NMP) to the above mixture, the weight of the solvent accounts for 5 times the total weight of the positive electrode material, stir at 60 ° C to dissolve the binder in it, and the mixture forms a uniform slurry, which is coated according to the conventional met...

Embodiment 02

[0073] According to the first method, a lithium secondary battery positive electrode containing simple Si nano additives is prepared. The elemental Si particles with a particle size of 800 nm, the conductive agent carbon black with an average particle size of 60 nm, the binder polyacrylonitrile (PAN) and the commercial positive electrode active material LiFePO with an average particle size of 5000 nm 4 well mixed. The addition of nano-Si powder accounted for 10% of the total weight of the positive electrode material. -4 times, the binder PAN accounts for 0.05 of the total weight of the positive electrode material, the conductive agent carbon black accounts for 0.085 of the total weight of the positive electrode material, and the positive electrode active material LiFePO 4 It accounts for about 0.865 times of the total weight of the positive electrode material.

[0074] Add the solvent N-methylpyrrolidone (NMP) to the above mixture, the weight of the solvent accounts for 5 ti...

Embodiment 03

[0077] According to the second method, lithium secondary battery electrodes containing C nano-additives were prepared. C powder with an average particle size of 200 nm and commercial positive active material LiNi with an average particle size of 6000 nm 0.8 co 0.2 o 2 Mix evenly; add the acetone solution of the binder PVdF (the concentration of PVdF is 0.2 g / ml) into the above mixture, and mix evenly again at 60° C. to make a slurry. The electrode is coated according to the conventional method, and can be used as the positive electrode after drying and rolling treatment. The amount of C powder added accounted for 10% of the total weight of the positive electrode material. -5 times, the binder PVdF accounts for 0.05 of the total weight of the positive electrode material, and the positive electrode active material LiNi 0.8 co 0.2 o 2 Accounting for about 0.950 times of the total weight of the positive electrode material. The dosages of binders, corresponding solvents and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com