Filter plate of filter press and method of manufacturing the same

A filter press and filter plate technology, applied in the field of filter plate and its manufacturing, can solve the problems of increased wall thickness, heavy weight, heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

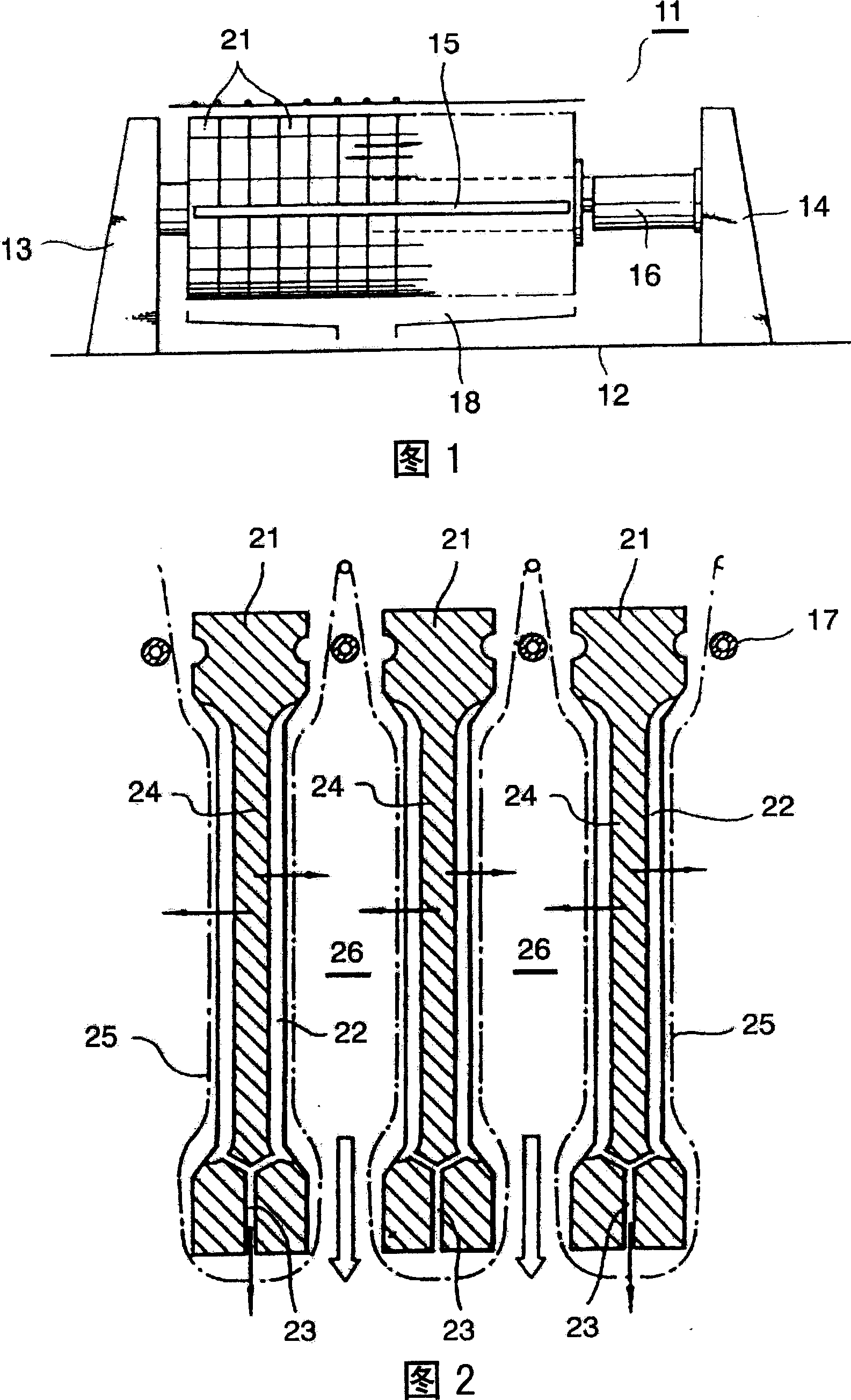

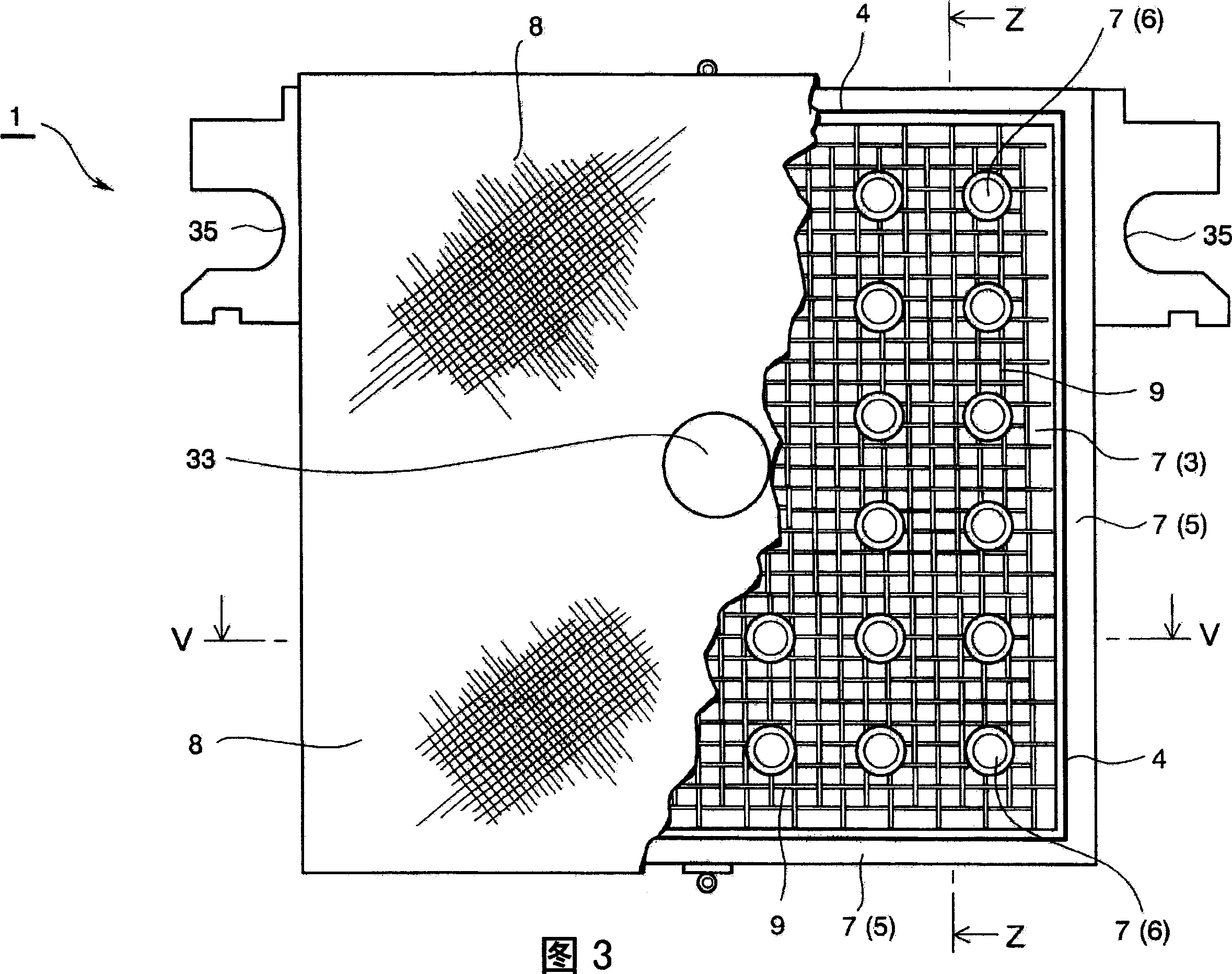

[0166] First, the general structure of the filter plate of the first embodiment of the present invention will be introduced according to FIGS. 3-6.

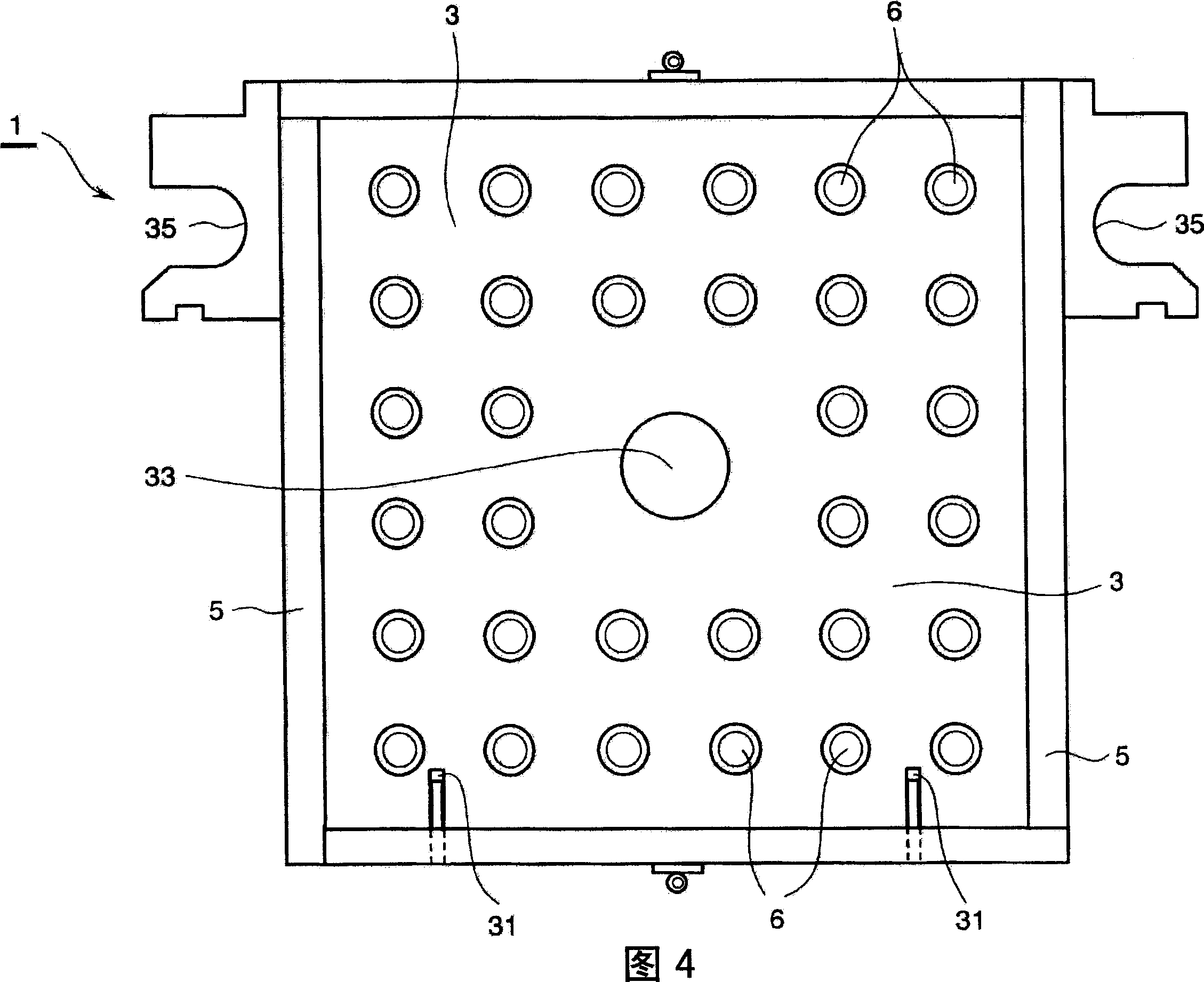

[0167] Fig. 3 is a front view showing the filter plate 1 of the first embodiment of the present invention (showing the state after cutting a part of the filter cloth 8);

[0168] Fig. 4 shows the state after the covering part 7, filter cloth 8 and mesh 9 are removed from the filter plate 1 shown in Fig. 3;

[0169] Fig. 5 is a cross-sectional view along the V-V line in Fig. 3, and the surroundings of the opposite frame parts 5, 5 clamping the filter plate main body 3 are enlarged and displayed;

[0170] Fig. 6 is a cross-sectional view along the line V-V in Fig. 3 , which enlarges and displays the surroundings of the opposing gaskets 6, 6 clamping the filter plate main body 3;

[0171] As shown in Figures 3 to 6, the filter plate 1 of the present invention has a filter plate main body 3 formed as a substantially square iron flat...

no. 2 Embodiment

[0213] The filter plate of the second embodiment of the present invention will be described below with reference to FIGS. 12 and 13 .

[0214] Fig. 12 is a front view showing the filter plate 1 of the second embodiment, showing a state where the covering member 7, the filter cloth 8 and the mesh 9 are removed from the filter plate.

[0215] FIG. 13 is a cross-sectional view showing the filter plate 1 according to the second embodiment, showing the periphery of the frame member 5 in an enlarged manner.

[0216] Furthermore, the description of the same parts as those of the above-mentioned first embodiment is omitted, and only the main points of difference are described.

[0217] In the filter plate 1 of the second embodiment, the O-ring 4 is made of the same material as the covering member 7 and is integrally formed. The frame member 5 is formed by frame assembling four elements having the same shape and the same size. As shown in FIGS. 12 and 13 , the frame member is arrange...

no. 3 Embodiment

[0219]The filter plate of the third embodiment of the present invention will be introduced below with reference to FIG. 14 . FIG. 14 is a cross-sectional view showing a filter plate according to a third embodiment of the present invention, showing the periphery of the frame member 5 in an enlarged manner. Furthermore, the description of the same parts as those of the above-mentioned second embodiment is omitted, and only the main points of difference are described.

[0220] In the filter plate of the third embodiment, the recessed portion 55 is formed in the frame member 5 along the longitudinal direction. When welding the frame member 5 to the filter plate main body 3 , as shown in FIG. 13 , the end of the filter plate main body 3 is fitted into the recess 55 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com