Electric double layer capacitor

一种双电层电容器、电容的技术,应用在电解电容器、电容器、混合电容器电极等方向,能够解决没有提到电解质等问题,达到优异高电流充/放电特征、优异耐久性、低内阻增加度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] (1) Preparation of positive electrode assembly

[0101] Prepare the coating slurry of positive pole polarizable electrode as follows: use N-methylpyrrolidone (NMP) as coating solvent, according to the weight ratio of 85:8:7, mix activated carbon Maxsorb MSP20 (Kansai Coke and Chemical Co., Ltd. production; BET specific surface area is 2300m 2 / g; pore volume 1.07mL / g; 50% particle size 9.5μm), conductive material (HS-100; DenkiKagaku Kogyo KK) and binder polyvinylidene fluoride (Sigma-Aldrich Japan KK; weight average molecular weight 534000 ).

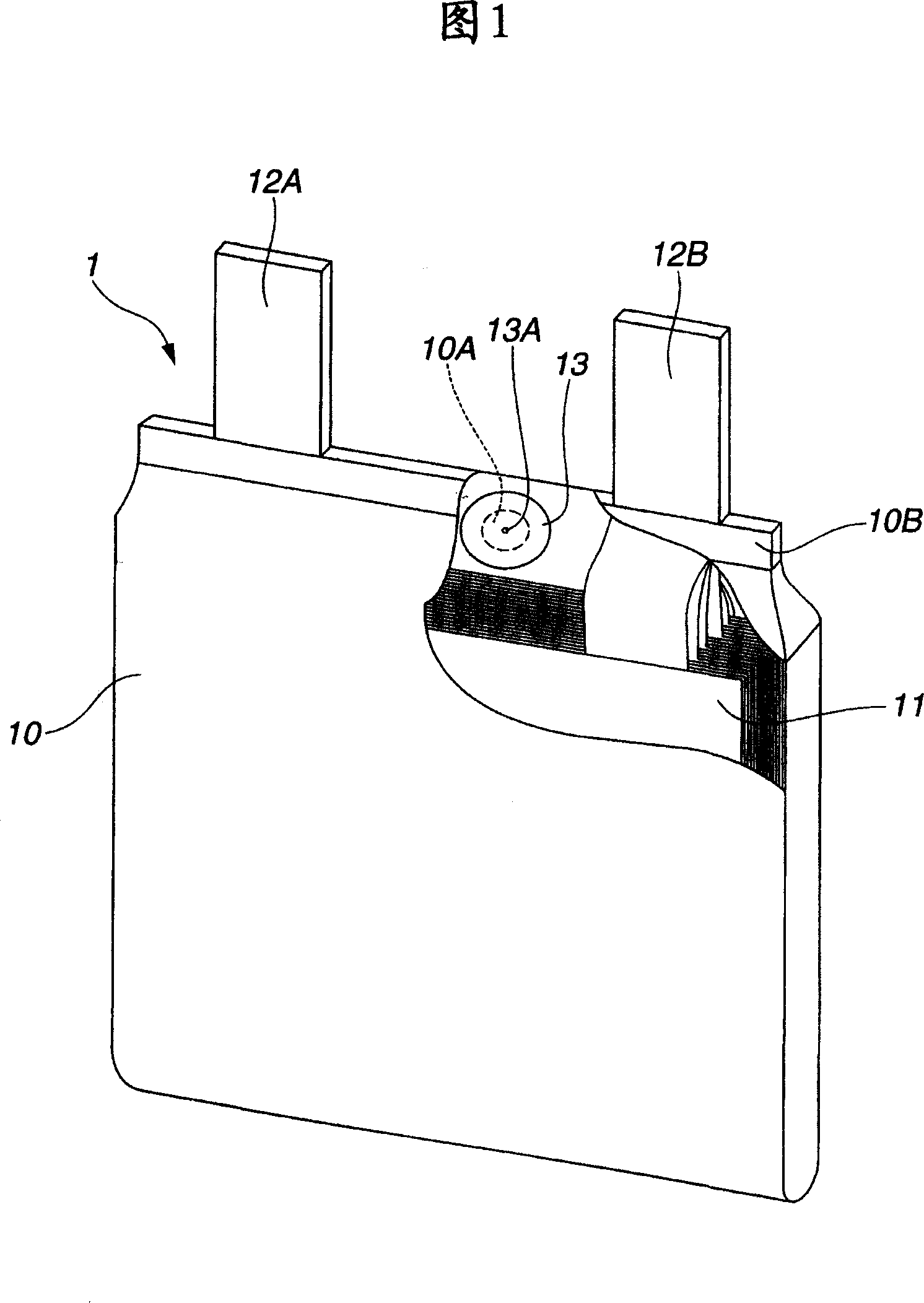

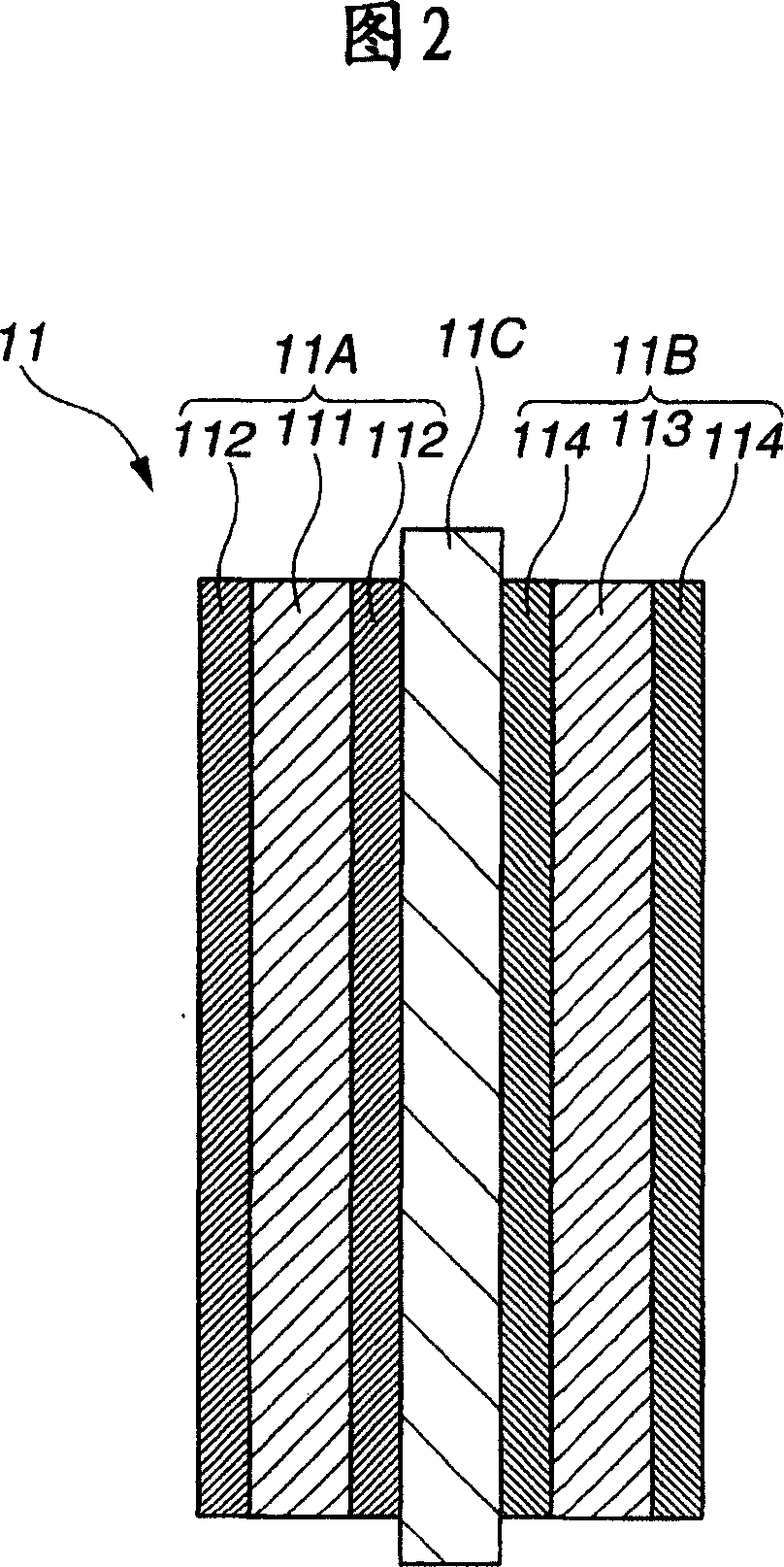

[0102] The slurry is coated on both sides of an etched aluminum foil (30CB; Nippon Capacitor Industry Co., Ltd.) as a positive electrode current collector 111, and then the aluminum foil is wound with a roll press, and dried to remove NMP to form a positive polarizable electrode 112, thereby forming a positive polarizable electrode. Polarized electrode assembly 11A. In this electrode assembly 11A, the apparent surface area of...

Embodiment 2

[0112] An electric double layer capacitor was prepared in the same manner as in Example 1, except that the thickness of the negative polarizable electrode formed on the collector side was set to 85 μm, and the amount of the organic electrolyte added was changed to 39 mL.

Embodiment 3

[0114] An electric double layer capacitor was prepared in the same manner as in Example 1, except that the thickness of the negative polarizable electrode formed on each side of the current collector was set to 90 μm, and the amount of the organic electrolyte added was changed to 41 mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com