Active hydraulic energy storage device loop

A technology of hydraulic accumulator and hydraulic pipeline, applied in the direction of accumulator device, fluid pressure actuating device, etc., can solve problems such as inconvenience of use, improve acceleration and deceleration ability, improve adaptability and power utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

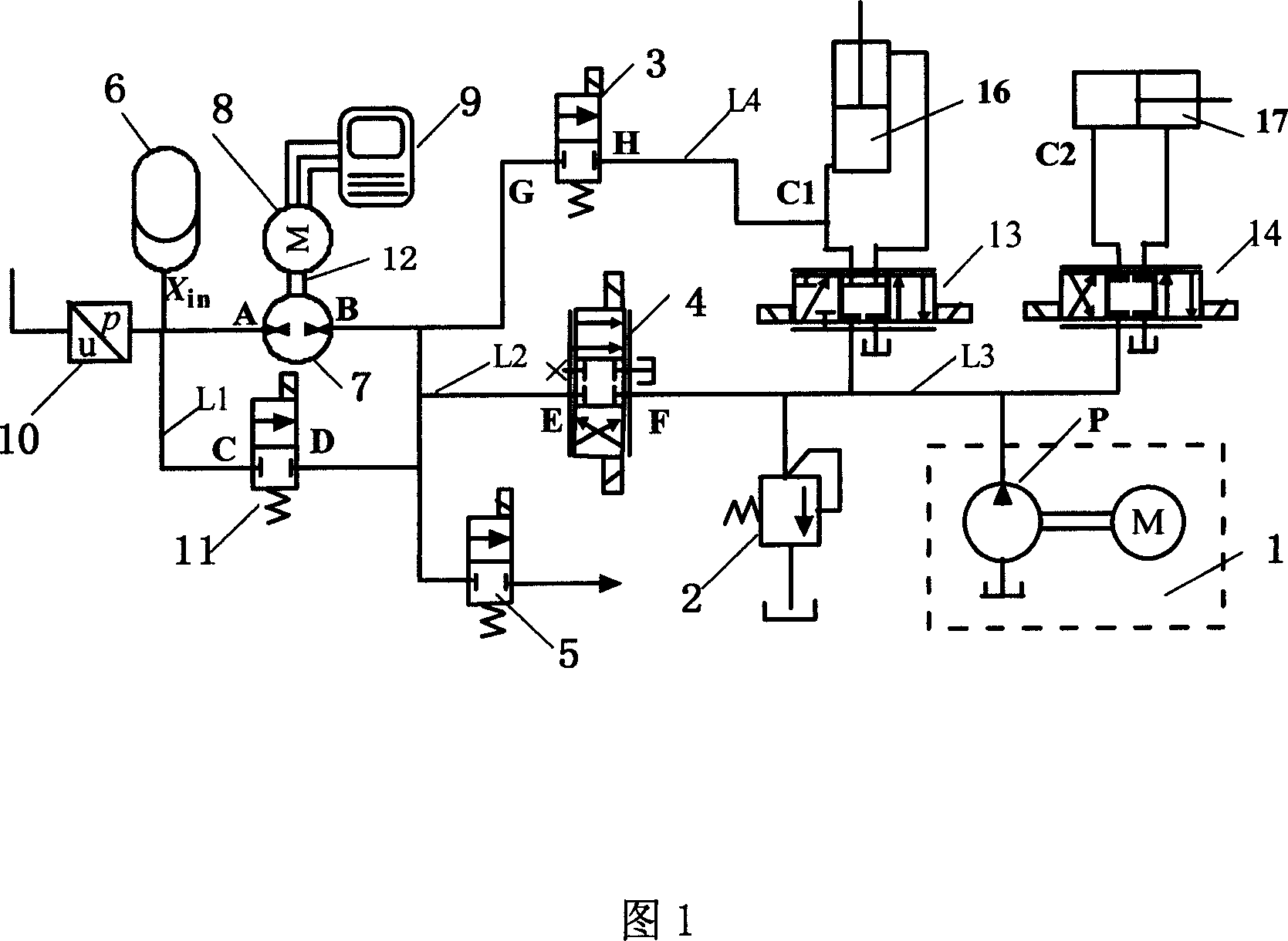

Embodiment approach 1

[0013] The active hydraulic accumulator circuit of the present invention is composed of a hydraulic power source 1, a safety valve 2, a two-position two-way electric control valve I 3, a directional control valve 4, a two-position two-way electric control valve II 5, and a hydraulic accumulator 6 , hydraulic pump 7, electric motor 8, motor speed controller 9, pressure sensor 10, two-position two-way electric control valve III 11, coupling 12, hydraulic cylinder I 16, hydraulic cylinder II 17, hydraulic pipelines L1, L2, L3, L4 and ports A, B, C, D, E, F, G, H, P, x in , The hydraulic cylinder is composed of rodless cavity C1, C2 and so on. The hydraulic power source 1 is a device that provides power to the entire system, and it can be in any form that can be used at present. Safety valve 2 is to limit the maximum pressure of the system and play a role in safety protection of the system. Two-position two-way electric control valve I 3, directional control valve 4, two-positio...

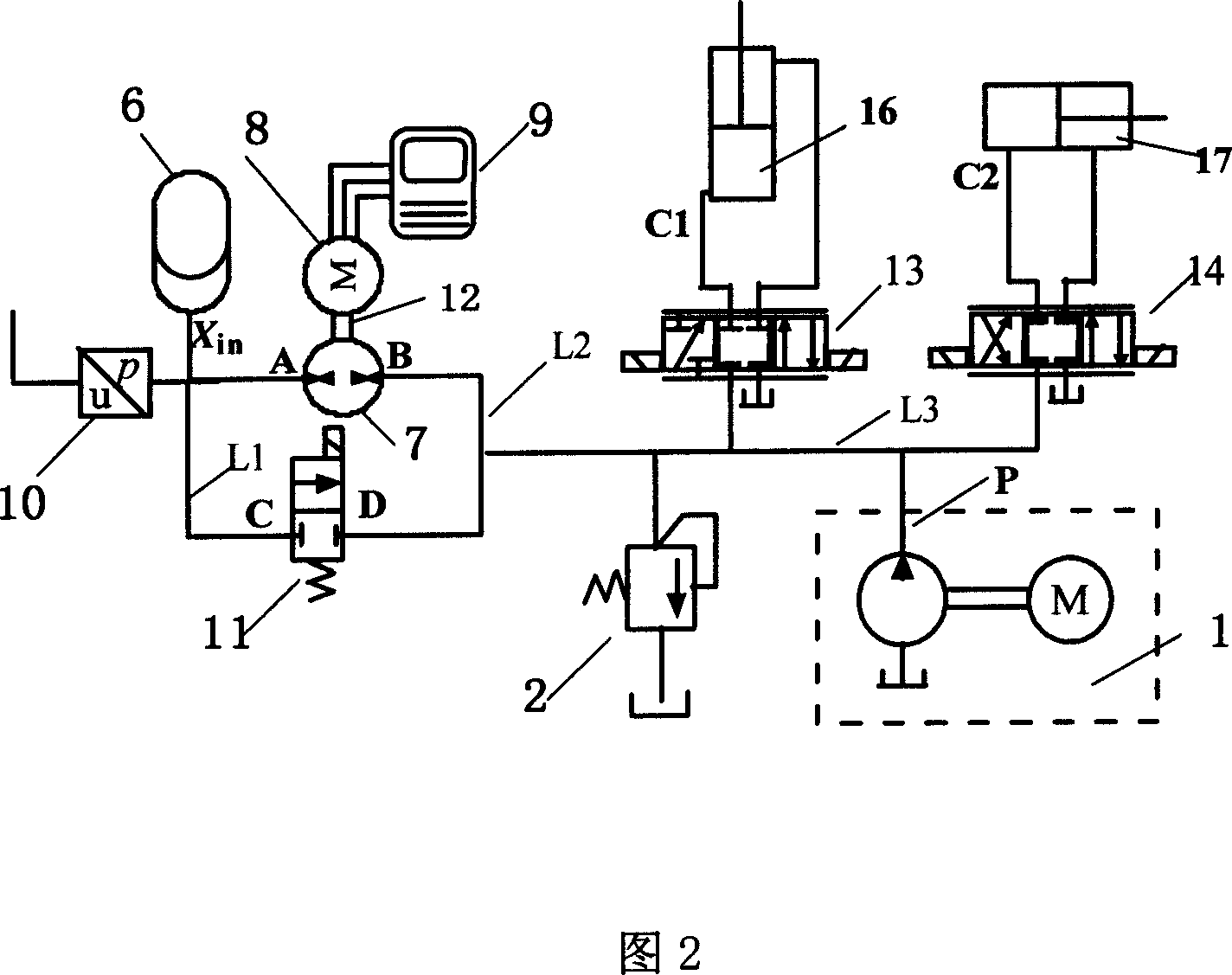

Embodiment approach 2

[0017] The active hydraulic accumulator circuit of the present invention is as described in Embodiment 1, and the hydraulic pipeline L2 can be directly communicated with the hydraulic pipeline L3 without passing through the directional control valve 4 .

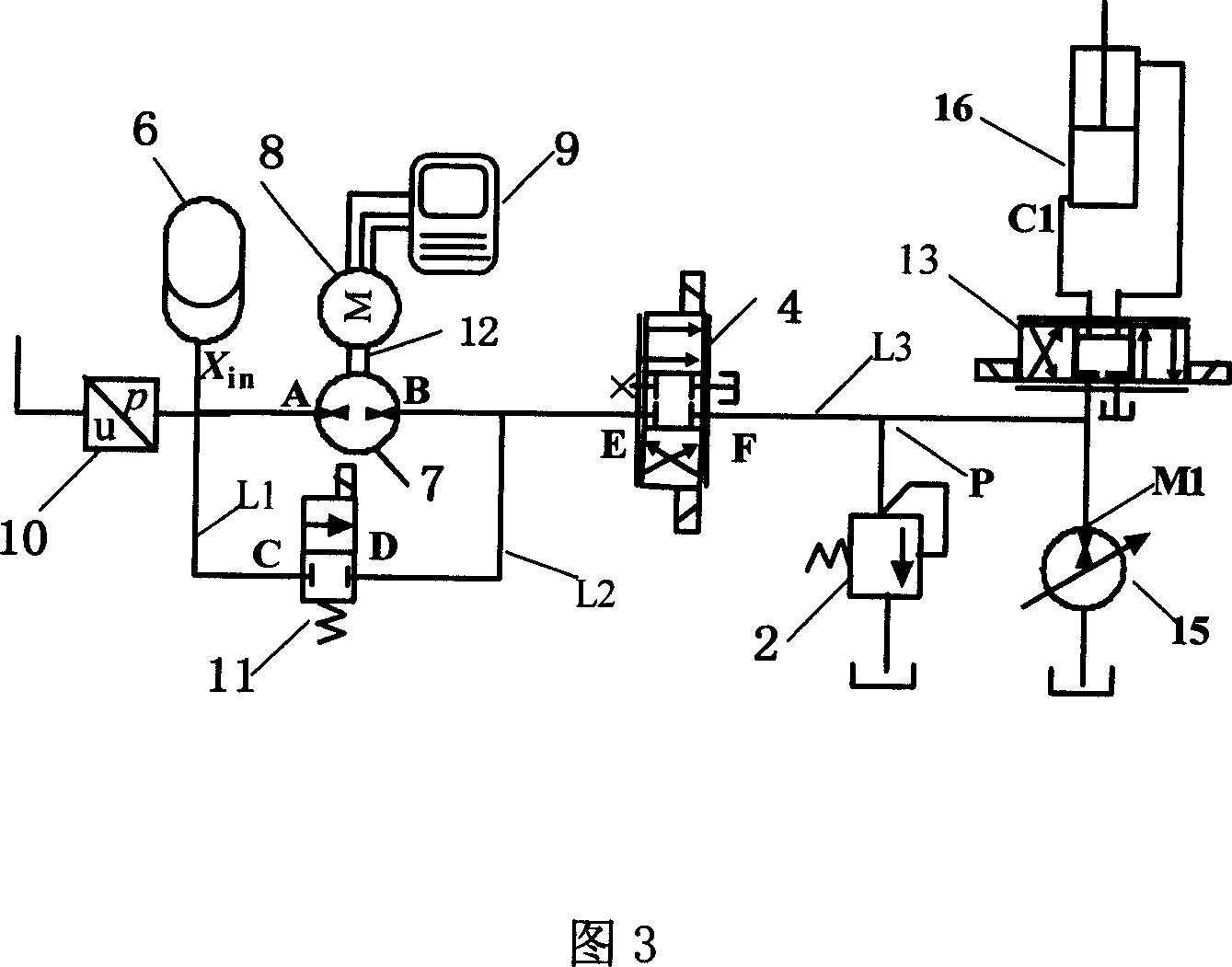

Embodiment approach 3

[0019] The active hydraulic accumulator circuit of the present invention is described in Embodiment 1, and more than one accumulator 6 is provided to form an accumulator group; more than one two-position two-way electric control valve II 5 is set on the pipeline L2 to communicate with one The above hydraulic cylinder II 17 constitutes multiple sets of two-position two-way electronically controlled valves and hydraulic cylinders, thereby constituting a multi-unit active hydraulic accumulator circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com