Flame ionization detector

A flame ionization and detector technology, applied in the field of gas chromatograph, can solve the problems of low collection rate and large signal noise, and achieve the effects of reducing signal noise interference, improving signal collection efficiency, and small detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

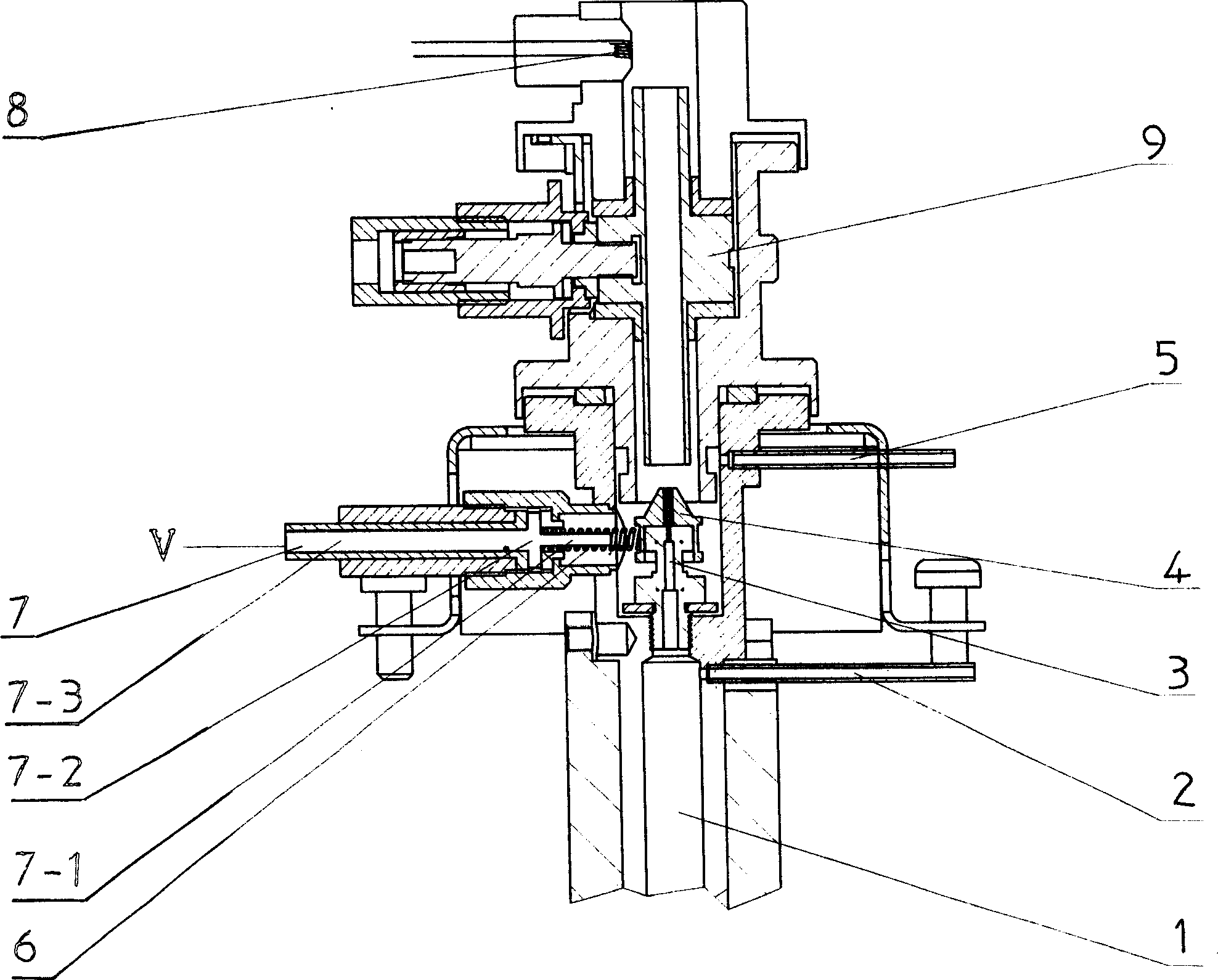

[0009] The accompanying drawing is a schematic diagram of the improved flame ionization detector structure of a gas chromatograph, consisting of a sample port 1, a hydrogen port 2, a nozzle 3, an air port 5, an ignition coil 8, a collector 9, and a nozzle Cap 4, spring 6, axle 7 are made up; Wherein the center of axle 7 has protruding ring 7-2, and its one end 7-1 is sheathed with spring 6, and its other end 7-3 is connected with negative high-voltage power supply V, and wherein cap top has through The nozzle cap 4 of the hole is installed on the nozzle 3 to form a polarized pole; one end of the spring 6 is in contact with the side of the nozzle cap 4, and the other end is in contact with the flange 7-2 of the shaft 7; wherein the ignition coil 8 is installed on the collector pole 9 above. Wherein the ignition coil 8 is made of cheap nickel-chromium wire to replace the current expensive platinum wire, which can achieve the same effect, thereby reducing the manufacturing cost. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com