Production method of ferrous oxalate special for ferrous lithium phosphate

A technology of ferrous oxalate and a production method, which is applied in the field of preparation of known fine chemicals and can solve problems such as single crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] 1. Ferrous sulfate pretreatment

[0018] Put ferrous sulfate into a stainless steel water washing kettle, add pure water (distilled water) to stir and wash for 2 to 3 times, filter and separate, add the washed ferrous sulfate into an enamel dissolution kettle, add pure water to stir and dissolve, adjust pH with sulfuric acid To 3, add 2% sucrose at the same time, stir and dissolve, then stand still, clarify, and after filtration and separation, pump the ferrous sulfate clarified solution into the storage tank for subsequent use.

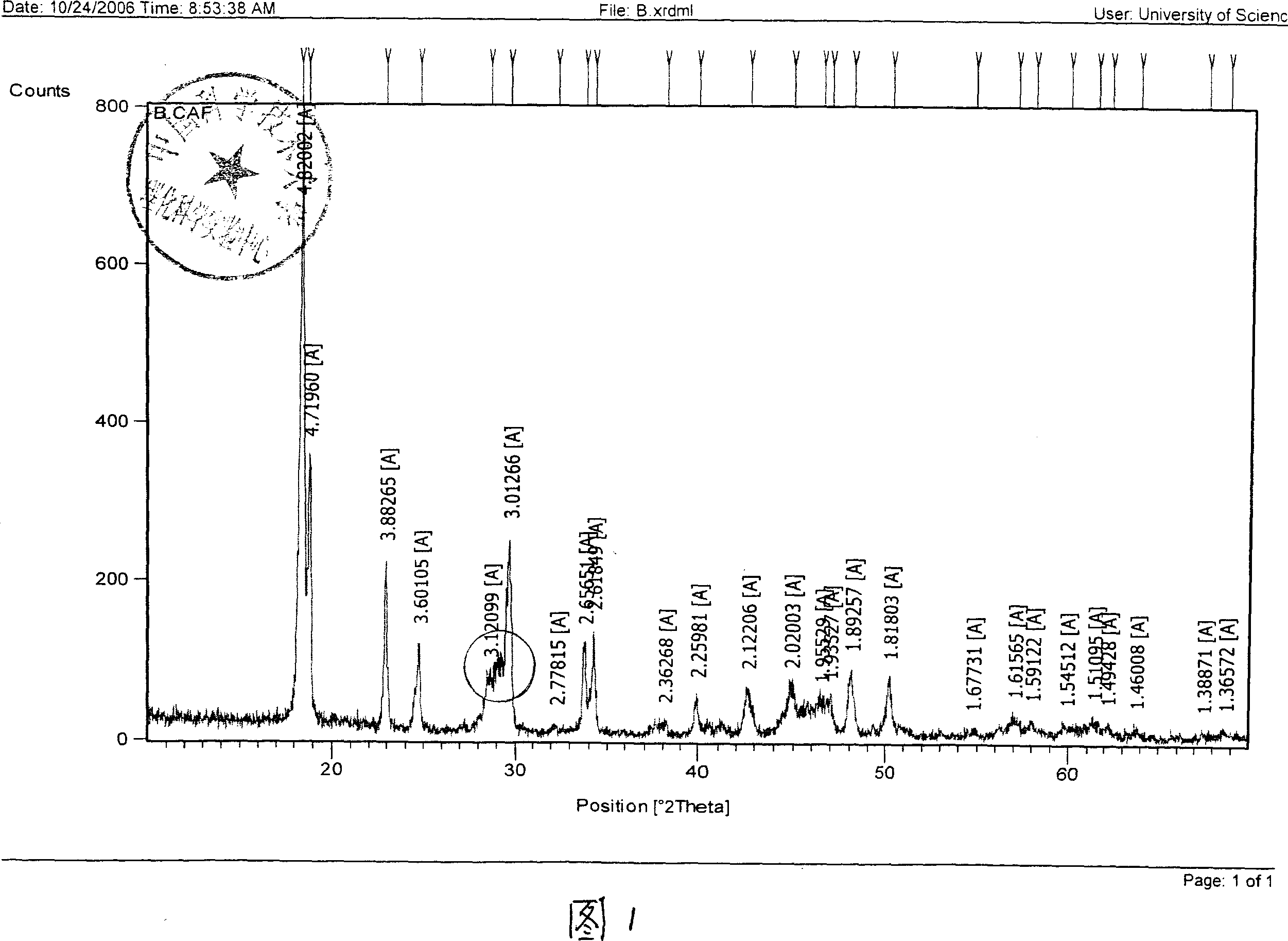

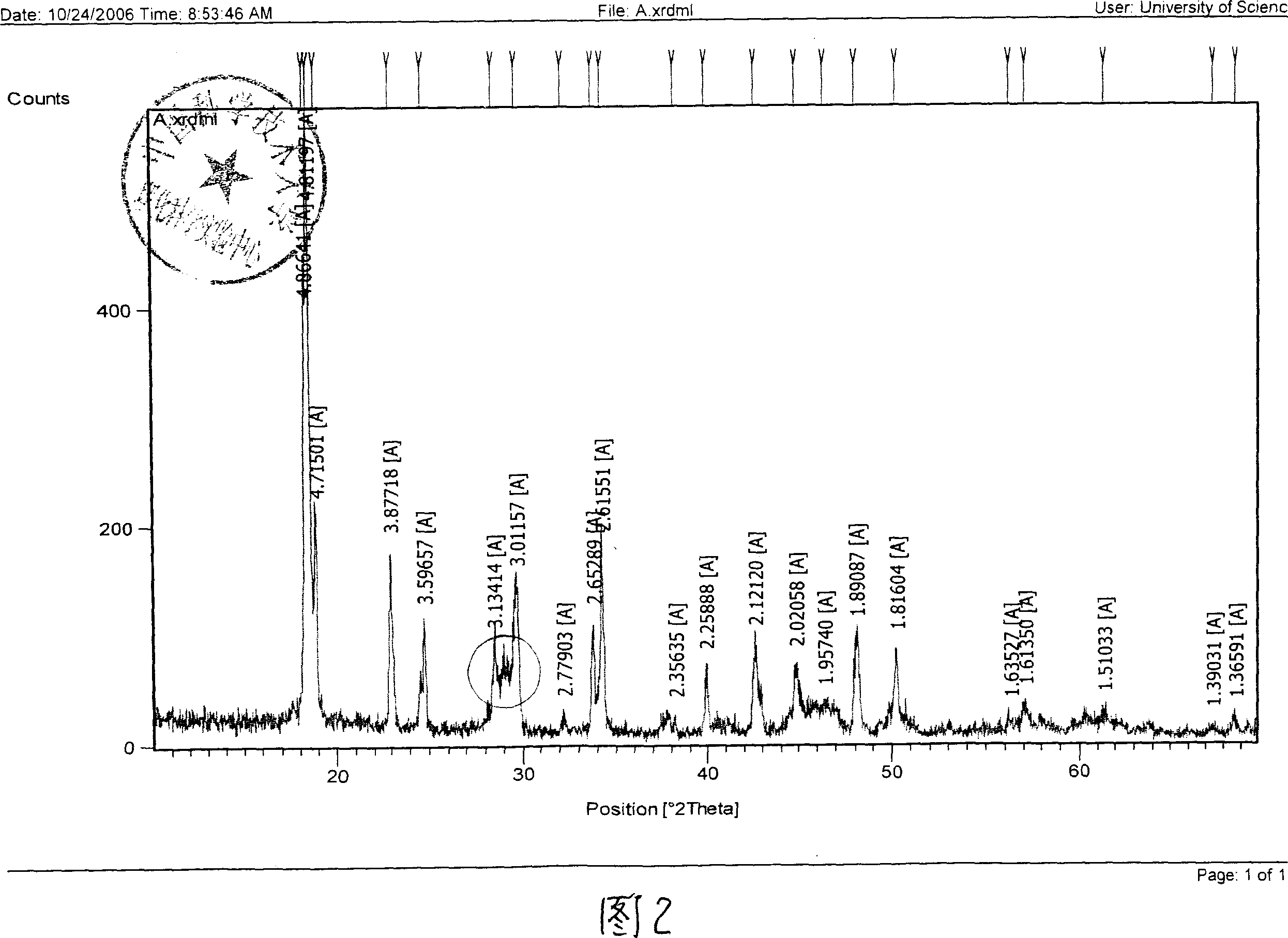

[0019] 2, the synthesis of ferrous monoclinic oxalate

[0020] Add oxalic acid and pure water into a stirring enamel synthesis kettle, stir and dissolve, and control the concentration of oxalic acid to 35-50 wt%. Slowly pass ammonia under stirring, at this time, the temperature in the kettle rises, when the temperature rises to 85-95°C (at this time, the ammonium acid ratio is about 7.5-3.5), stop passing ammonia, and add ferrous sulfate solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com