Polarization keeping optical fibre axis fixing method based on space diffracting light and device thereof

A technology of polarization-maintaining optical fiber and diffracted light, which is applied in the direction of measuring devices, clad optical fibers, optical waveguides and light guides, etc., to achieve the effect of improving the quality of devices, improving quality, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The polarization-maintaining fiber used in the following embodiments is a panda-type polarization-maintaining fiber.

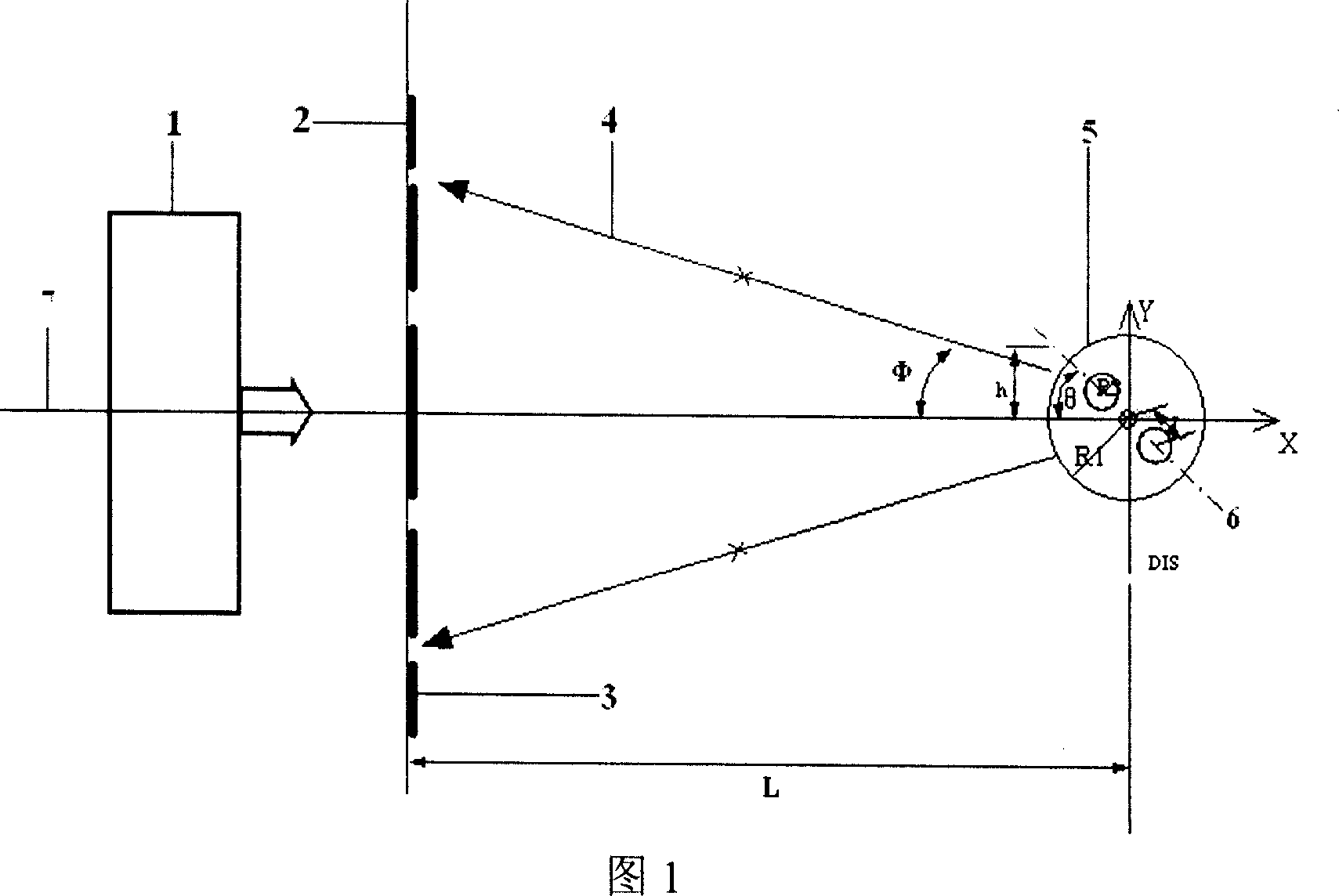

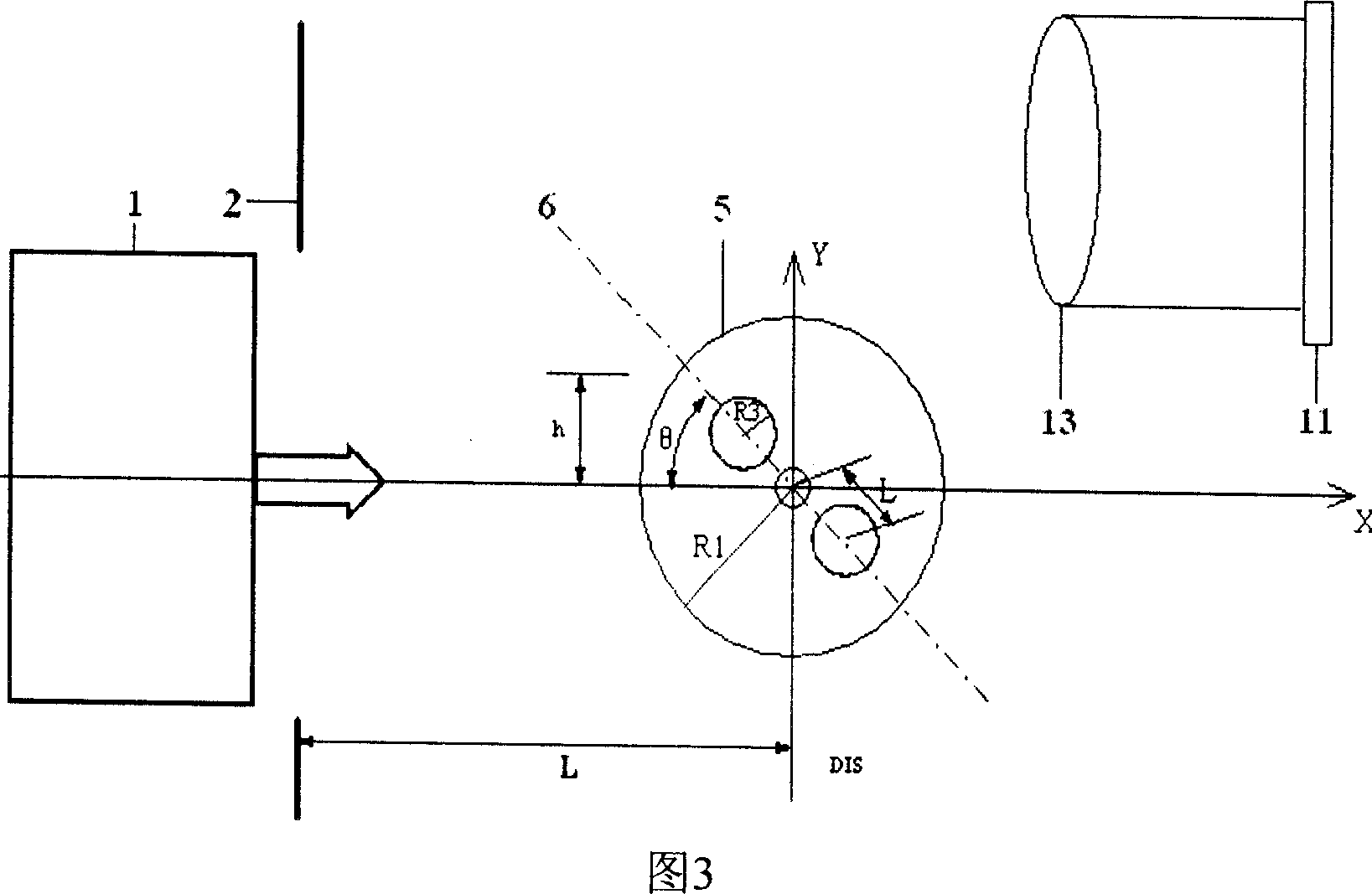

[0057] As shown in Figure 1, the laser beam 1 is perpendicular to the longitudinal axis of the polarization-maintaining fiber 5 and irradiates the side of the polarization-maintaining fiber 5 vertically, thereby forming backscattered light 4, which interferes with each other in space and is captured by the imaging screen Receiving, the diffraction image 3 can be seen through the reception of the imaging screen, and the characteristic quantities of these diffraction images have a one-to-one relationship with the polarization axis azimuth of the polarization-maintaining fiber. 7 indicates an optical axis.

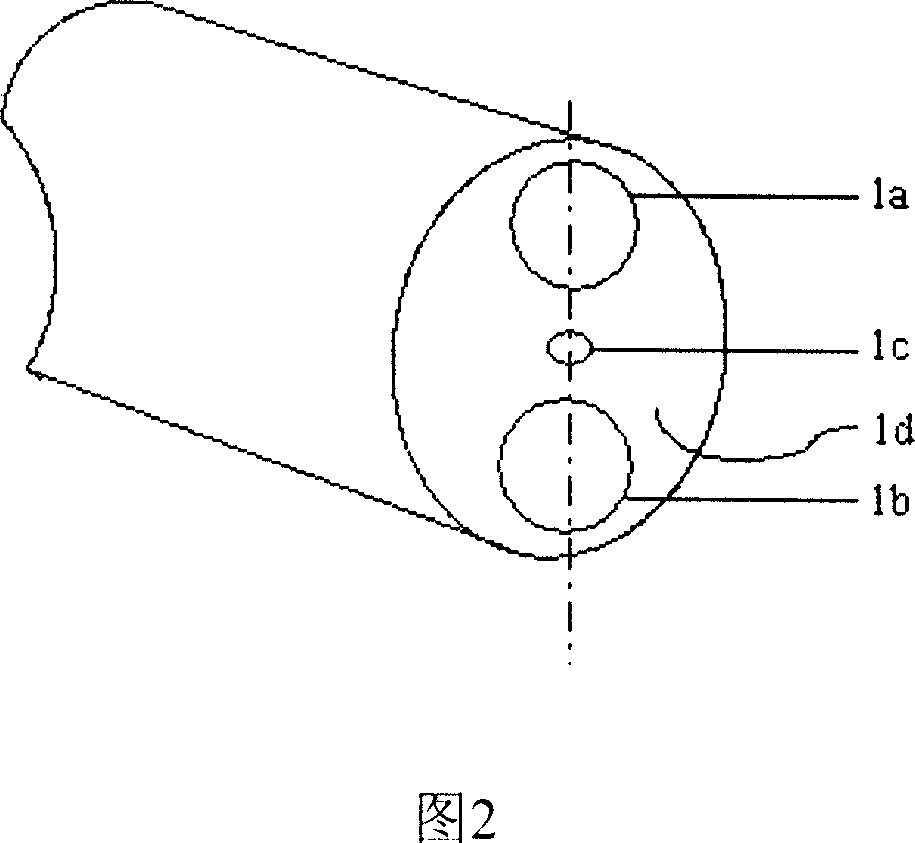

[0058] As shown in Figure 2, 1a and 1c are two stress regions, 1b is the core, and 1d is the cladding. This results in the formation of an acceptable diffraction image 3 on the observation plane 2 at a distance L from the center of the fiber. These d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com