Reactor for generating moisture and moisture generating and feeding apparatus using the same

A reaction furnace, water technology, applied to the chemical method of reacting gas medium and gas medium, the reaction of gas and gas under the catalytic active body, water, etc., can solve the problem that the main body of the reaction furnace cannot be enlarged and the cooling capacity can be improved , Can not cope with the increase of moisture generation, etc., to achieve the effect of improved cooling characteristics, improved rising speed, and less heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

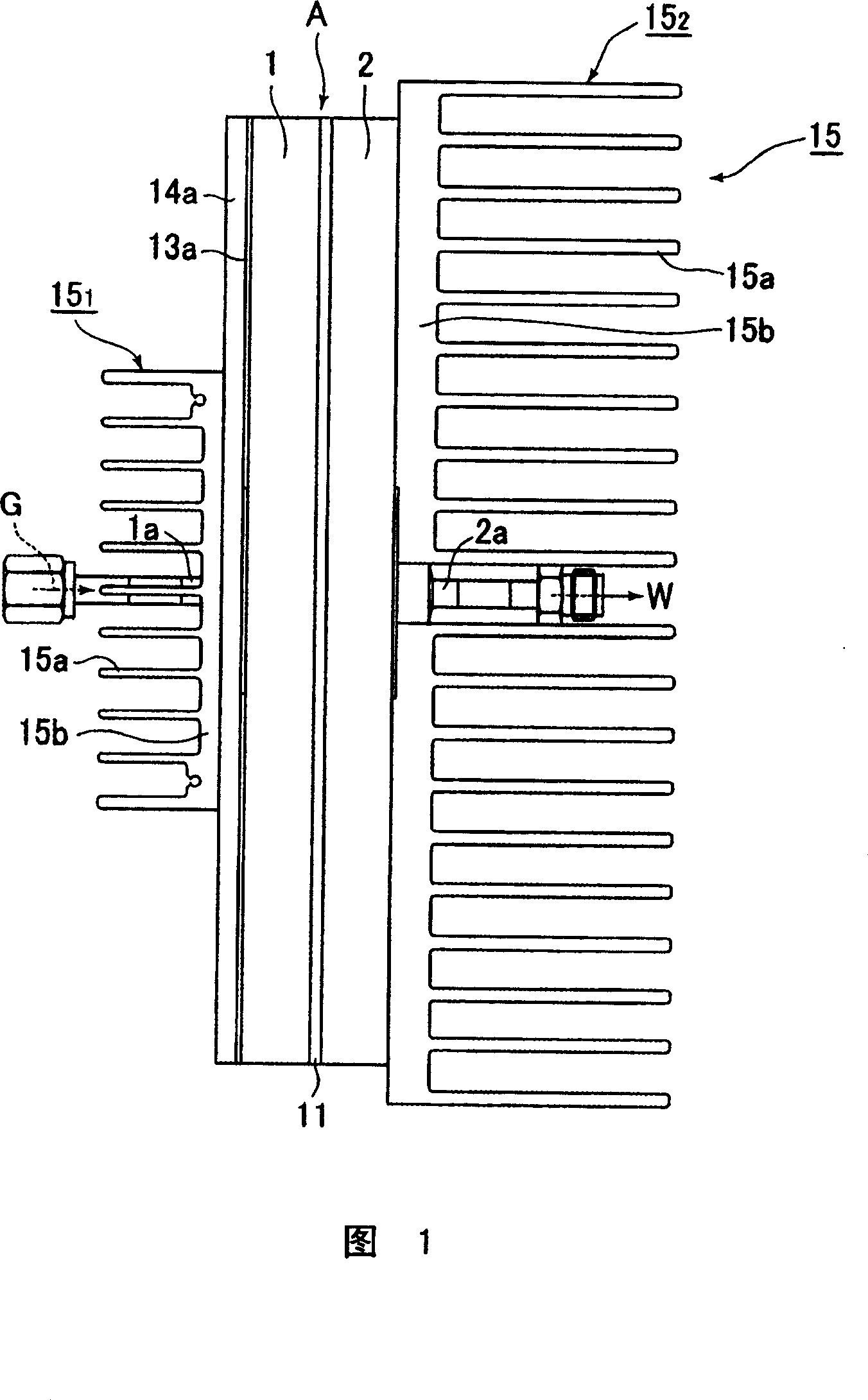

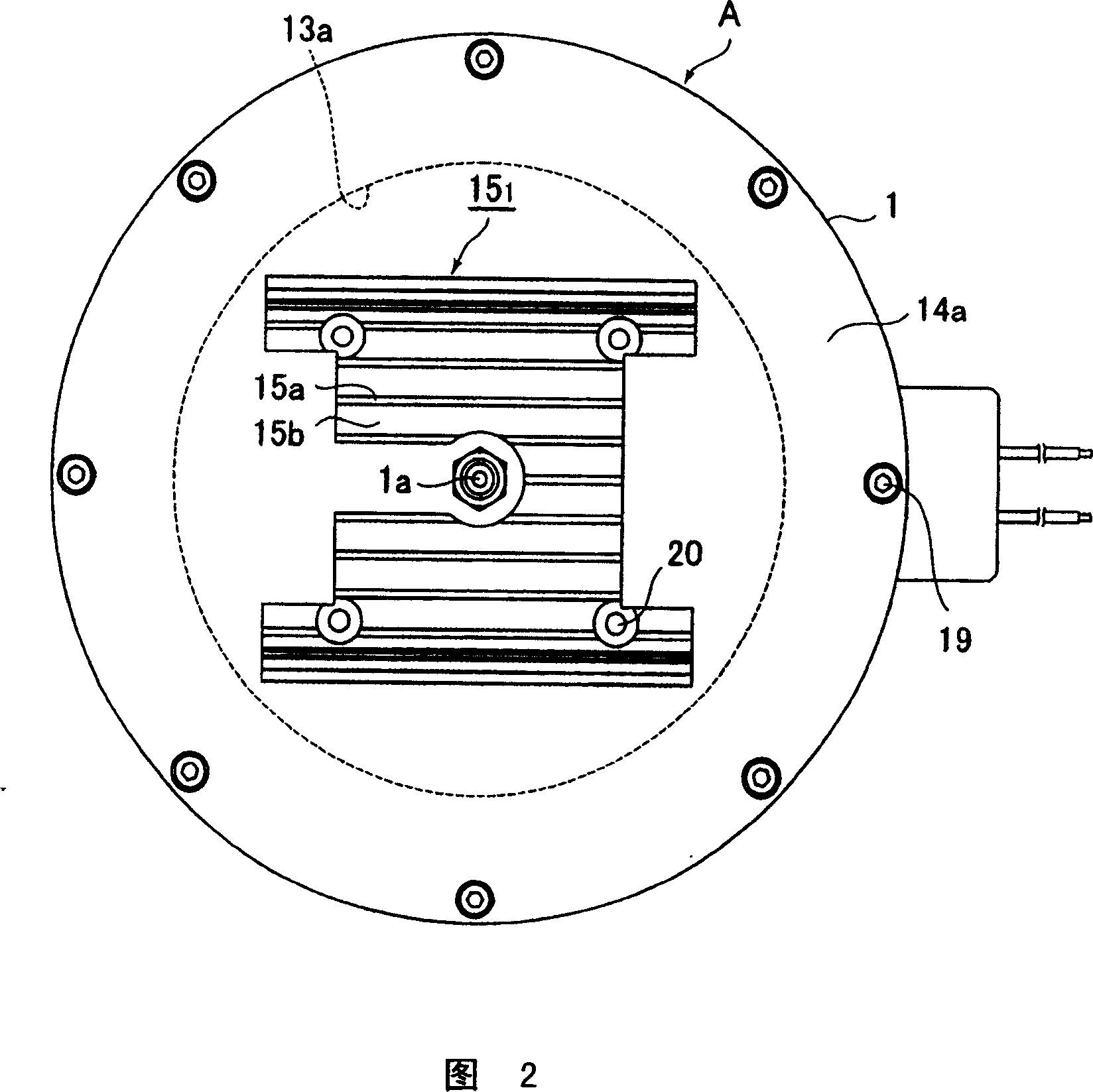

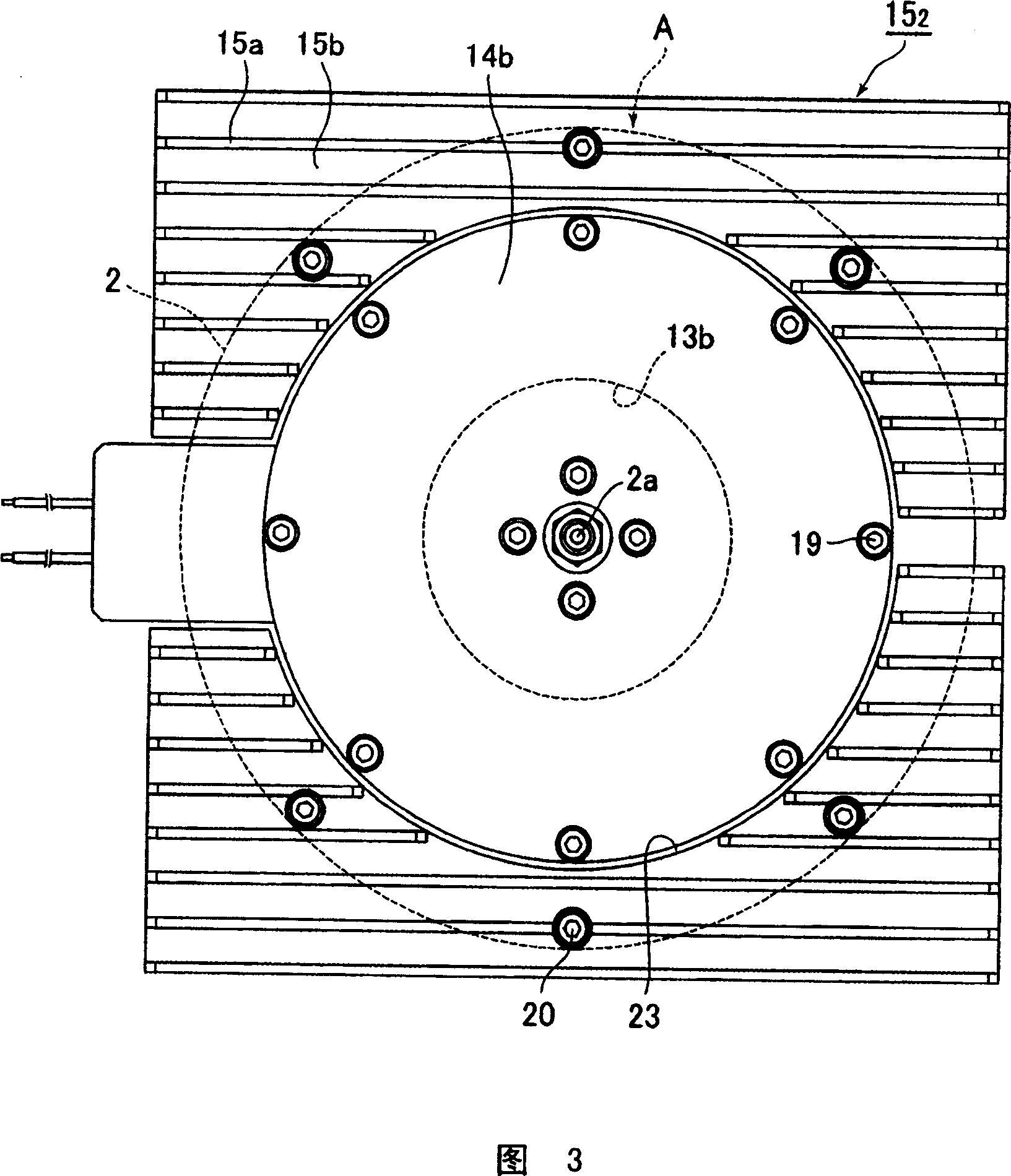

[0099] Among Fig. 1 to Fig. 4, make the external diameter of reaction furnace main body A be 228mmφ, thickness be 37mm, the thickness of internal space V be 17mm, the internal diameter of internal space V be 216mmφ, the thickness of reflector 3a, 3b is 3mm, and profile is 204mmφ, the gap L with the outlet side furnace body part 2 is 1mm, the distance with the inlet side furnace body part 1 is 1mm, the length of the conical surface is about 21mm (inclination angle α=8°), the platinum paint catalyst layer 6 (TiN Barrier coating 7 = 5 μm + pt paint coating 8 = 0.3 μm), and the barrier coatings 9 and 10 on the inner wall surface of the inlet side furnace body part 1 and the outer surfaces of the reflectors 3 a and 3 b are TiN (5 μm).

[0100] In addition, let the outer dimensions of the radiator substrate 15b of the cooler 15 be 235×235mm, and the thickness be 10mm, and the outlet side cooler 15 2 The inner diameter of the heater insertion hole 23 is 190mmφ, the height of the cool...

no. 2 Embodiment approach

[0106] Fig. 7 is a longitudinal sectional view of a moisture generating reactor according to a second embodiment of the present invention, Fig. 8 is a plan view thereof, and Fig. 9 is a right side view.

[0107] Referring to Fig. 7 to Fig. 9, the reaction furnace body A for moisture generation is formed by combining the inlet side furnace body part 1 and the outlet side furnace body part 2 of stainless steel (SUS316L) in an opposing shape and welding them in an airtight state. Circular hollow table shape.

[0108] The entrance-side furnace main body member 1 is provided with a circular concave portion with a planar bottom inside, and the gas supply port 1a communicates with the concave portion. In addition, in the outlet-side furnace main body member 2, a circular concave portion having a planar bottom surface is provided inside, and the water vapor outlet 2a communicates with the concave portion. Furthermore, flanges are respectively formed inwardly at the outer peripheral e...

Embodiment 2

[0124] Among Fig. 7 to Fig. 9, make the external diameter of reaction furnace main body A be 228mmφ, thickness be 37mm, the thickness of internal space V be 17mm, the internal diameter of internal space V be 216mmφ, the thickness of reflector 3a, 3b is 3mm, and profile is 204mmφ, the gap L with the outlet side furnace body part 2 is 1mm, the distance with the inlet side furnace body part 1 is 1mm, the length of the conical surface is about 21mm (inclination angle α=8°), the platinum paint catalyst layer 6 (TiN Barrier coating 7 = 5 μm + pt paint coating 8 = 0.3 μm), and the barrier coatings 9 and 10 on the inner wall surface of the inlet side furnace body part 1 and the outer surfaces of the reflectors 3 a and 3 b are TiN (5 μm).

[0125] In addition, let the inlet side cooler 15 1 and outlet side cooler 15 2 The outer dimensions of the radiator substrate 15b are 235×235mm, the thickness is 10mm, and the outlet side cooler 15 2 The inner diameter of the heater insertion hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com