Open-end spinning apparatus with fiber transport channel consisting of several channel structural components

An open-end, spinning machine technology, applied in open-end spinning machines, continuous winding spinning machines, spinning machines, etc., can solve problems such as unattainable quality, porosity, rough surface of the carded edge, etc., Achieve increased applicability and flexibility, simple interchangeability, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

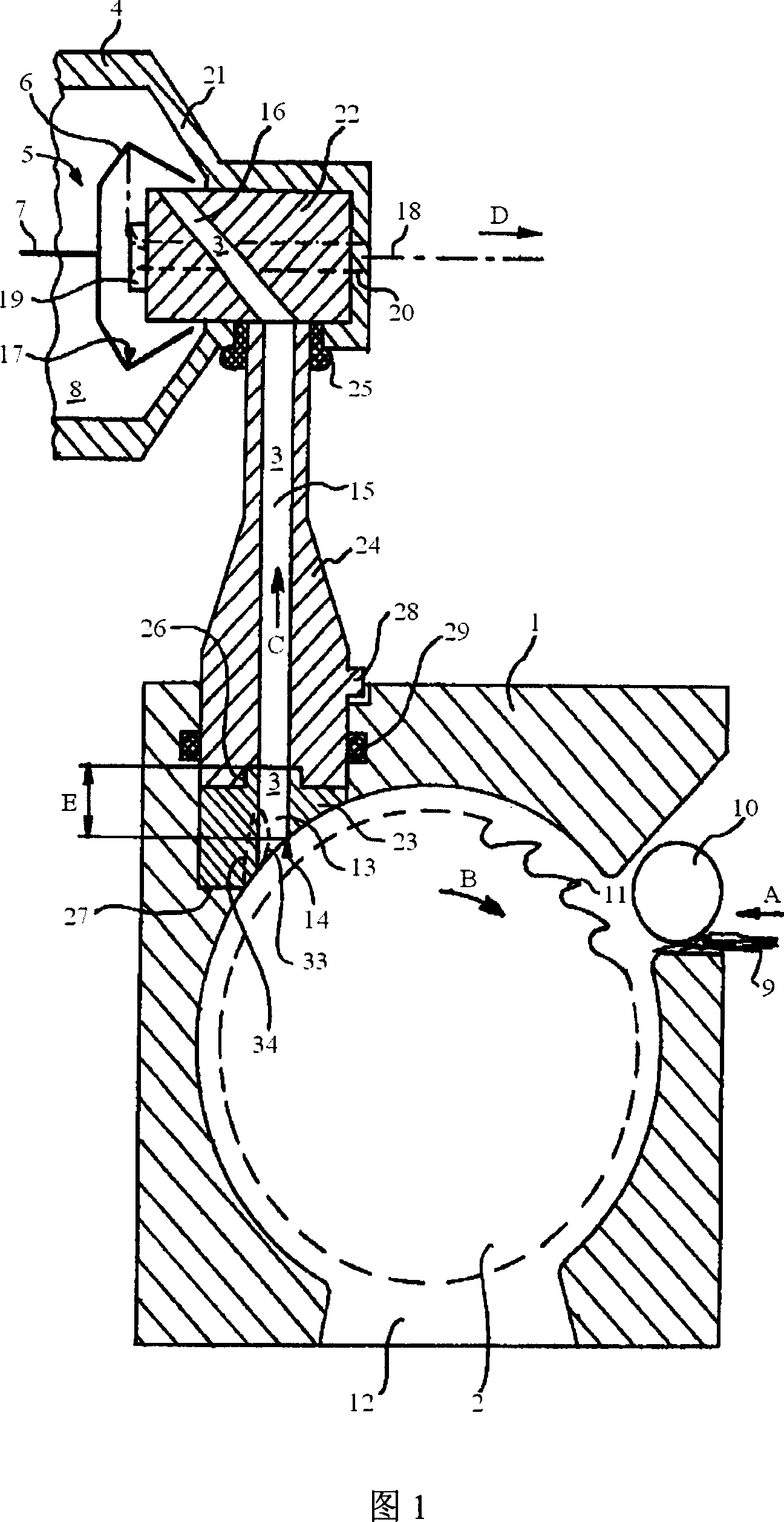

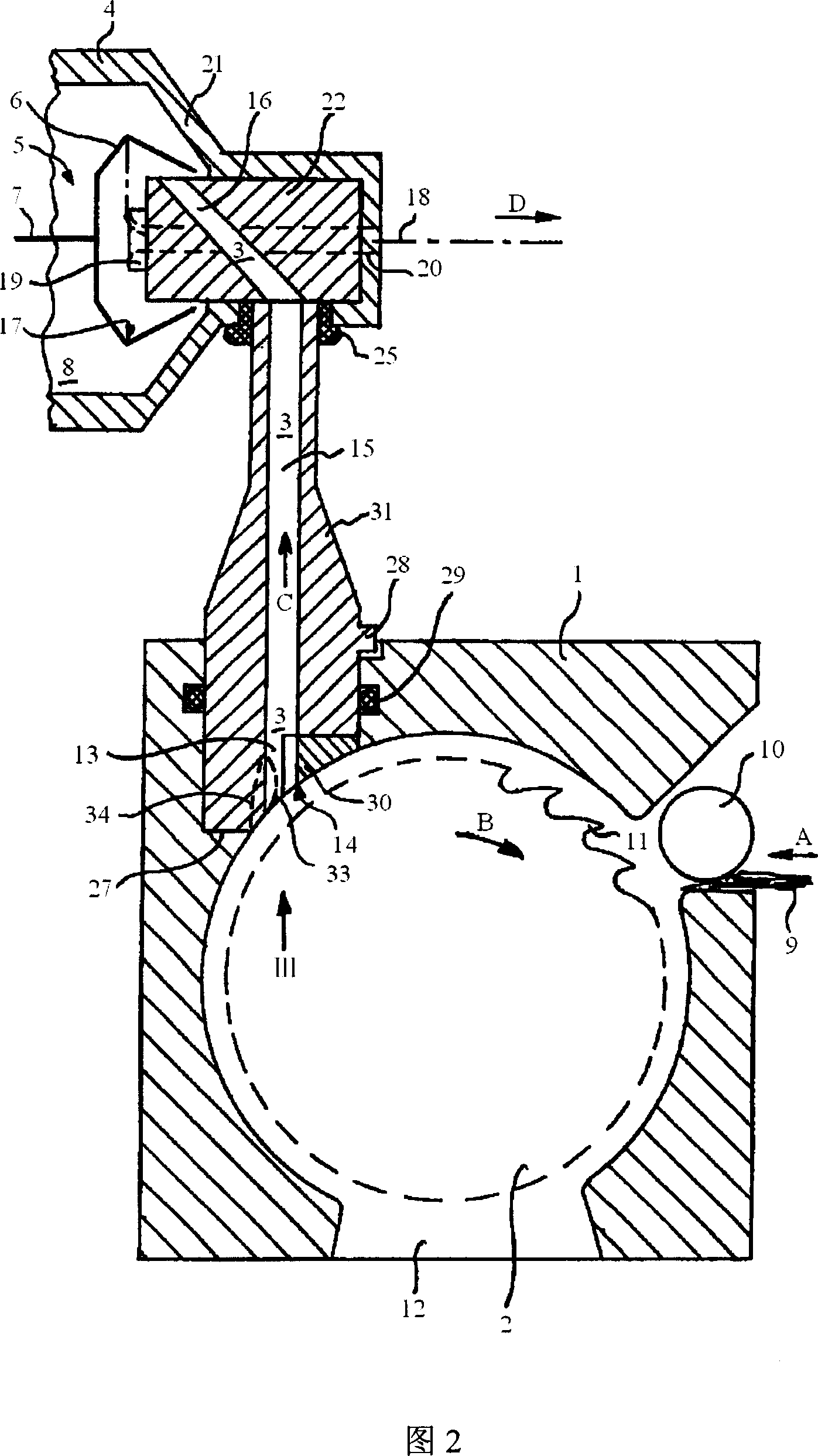

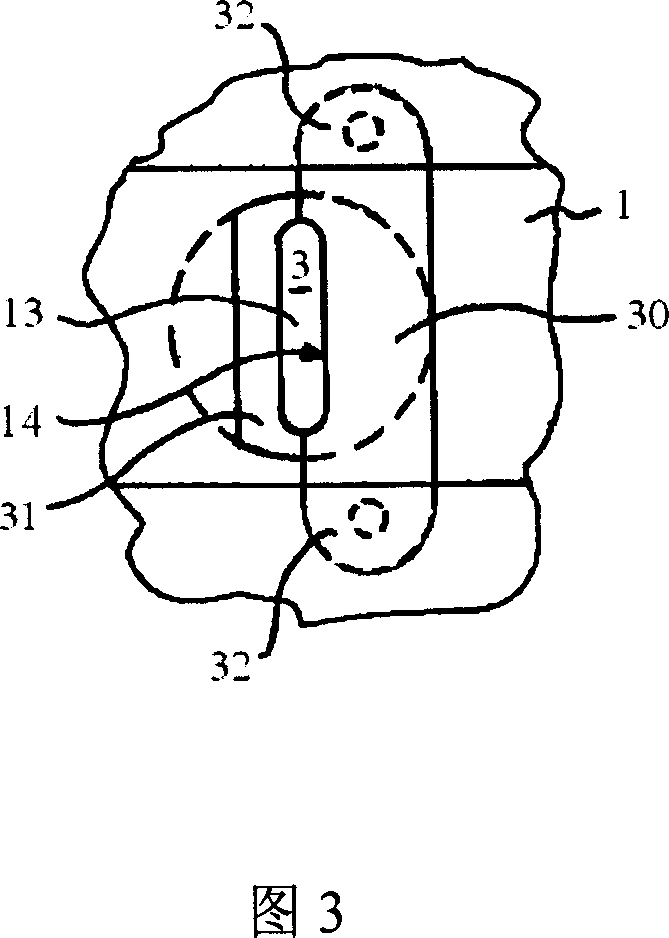

[0023] The open-ended spinning machine shown in FIGS. 1 and 2 comprises, as basic components, a card roll housing 1 with a card roll 2 , a fiber duct 3 and a spinning machine arranged in the rotor housing 4 . Yarn rotor 5. The spinning rotor 5 consists of a turntable 6 and a rod 7 pressed into the turntable. The rod 7 on the spinning rotor 5 and the card roller 2 are positioned and driven in a manner not shown in the figures. During operation, the turntable 6 rotates in the negative pressure chamber 8, and the negative pressure chamber 8 is formed by the rotor housing 4. The rotor housing 4 is connected to a negative pressure source, but the specific way is not shown in the figure.

[0024] The fibrous material is transported in the form of a fiber web 9 via a drivable feed roll 10 in the direction of the arrow A to the carding roll 2 . The fiber strip 9 is carded into finer fibers by the needles or teeth 11 (only schematically shown) arranged on the outer periphery of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com