Rotor blade for a wind turbine

A technology of rotor blades and blades, which is applied in the field of reducing the characteristics of noise generation, can solve problems such as high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The same reference numbers are used in all figures.

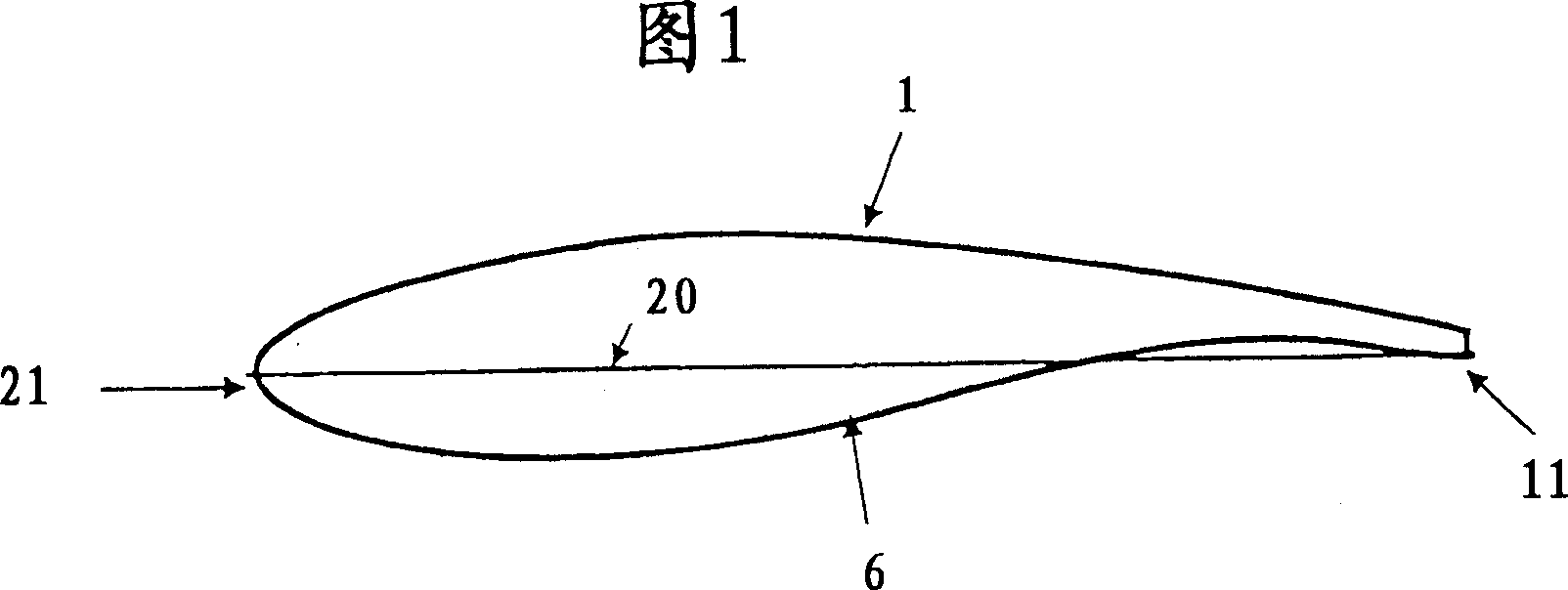

[0020] The rotor blade shown in cross section in FIG. 1 consists of an upper shell 1 and a lower shell 6 . The profile ends at the rear with a profile trailing edge 11 . The leading edge of the profile is defined by the profile nose 21 . The profile chord 20 is also shown in this figure.

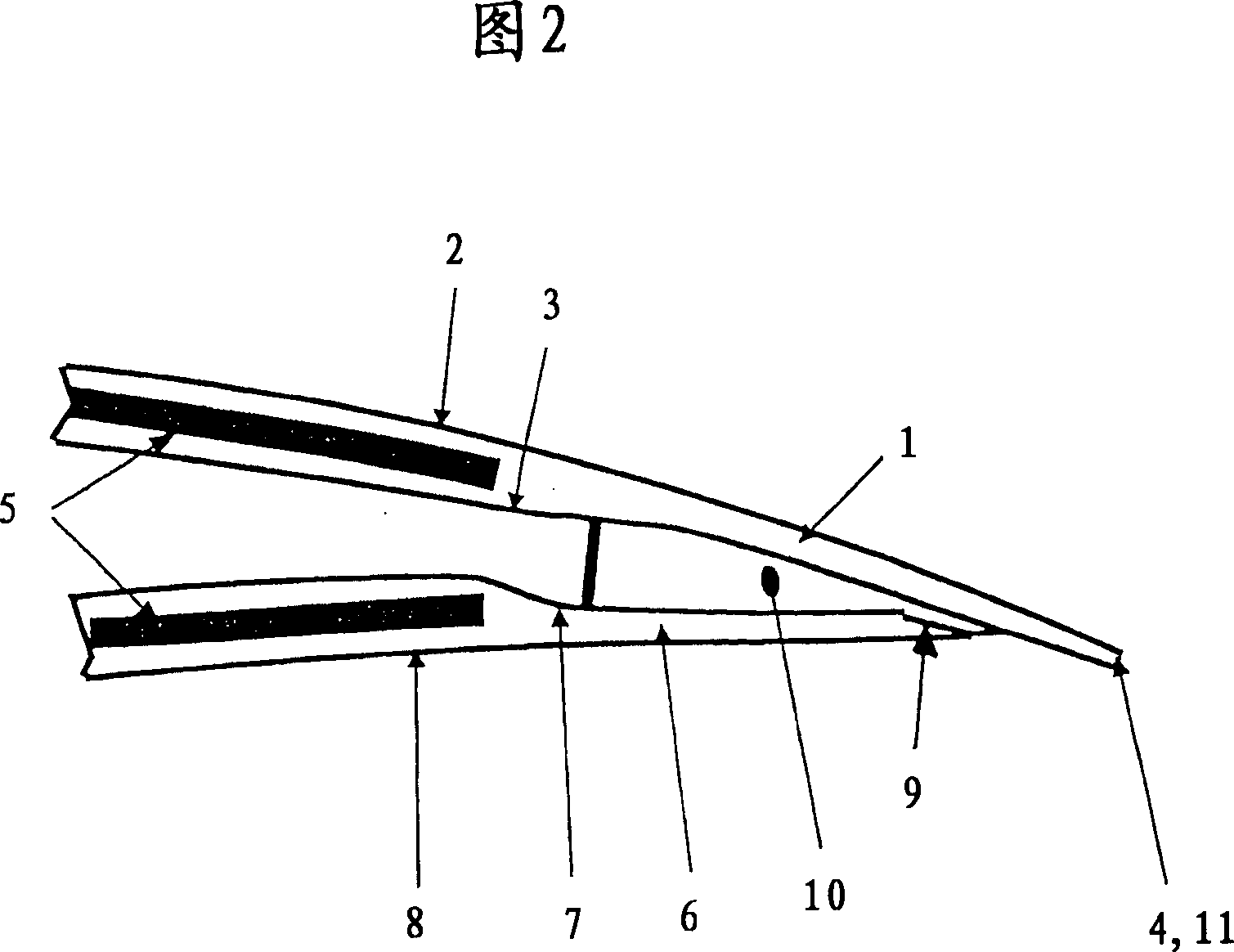

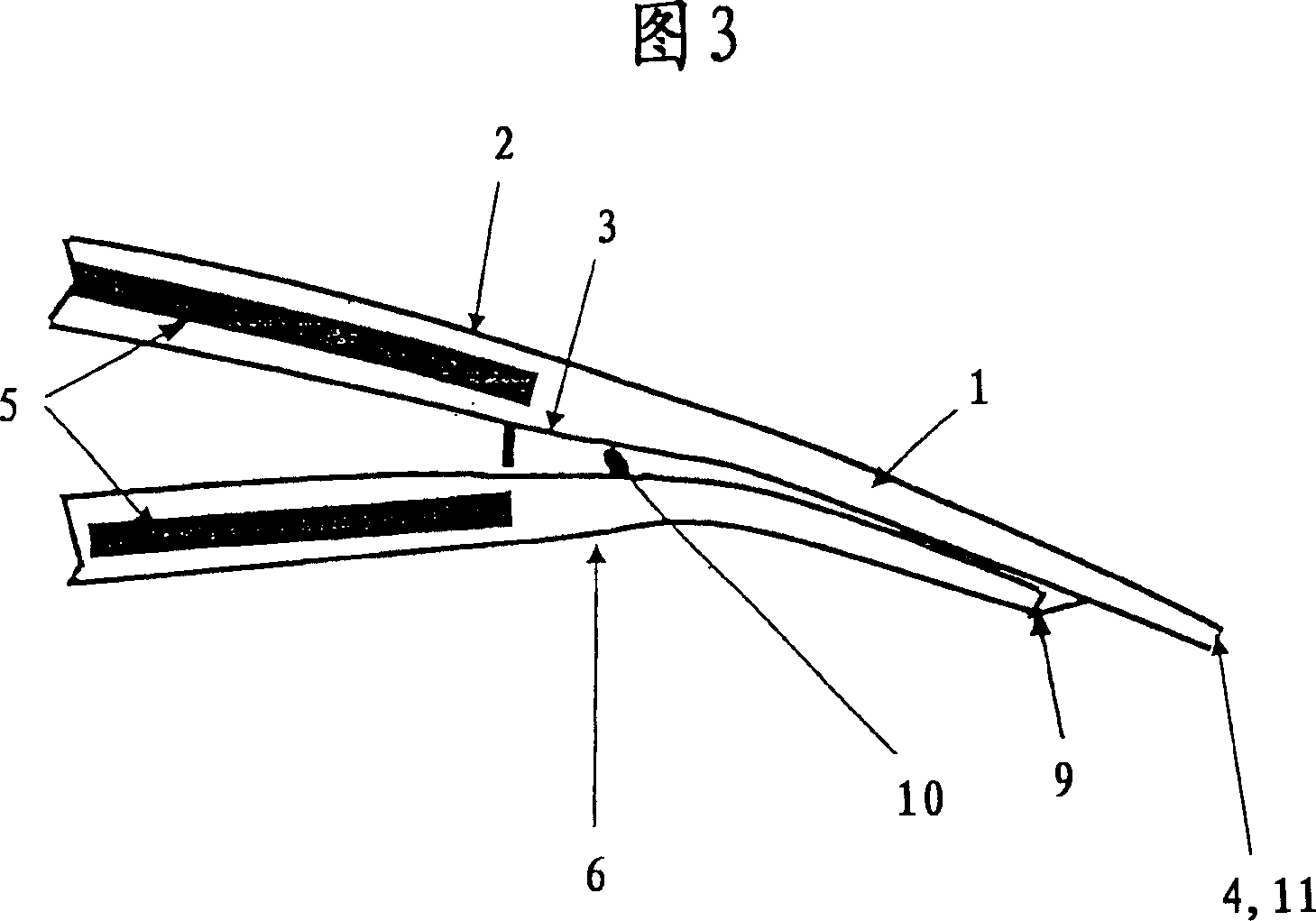

[0021] Figure 4 shows the prior art, showing a cross-section through the trailing edge of the rotor blade. The upper shell 1 has an exterior 2, an interior 3 and a trailing edge 4, and is partially filled with a spacer material 5, such as balsa wood or foam. The same applies to the lower shell 6 , which has an inner 7 , an outer 8 and a rear edge 9 . The area 10 between the two housing halves 1 , 6 is filled with adhesive to join the upper and lower housings 1 , 6 . Both the trailing edges 4 and 9 are consistent with the profile trailing edge 11 . The two trailing edges 4 , 9 define the thickness of the profiled trailing edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com