Fuel cell and fuel cell stacks equipped with this

A fuel cell and fuel gas technology, which is used in fuel cell parts, fuel cells, fuel cell additives, etc., and can solve problems such as difficulty in maintaining power generation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

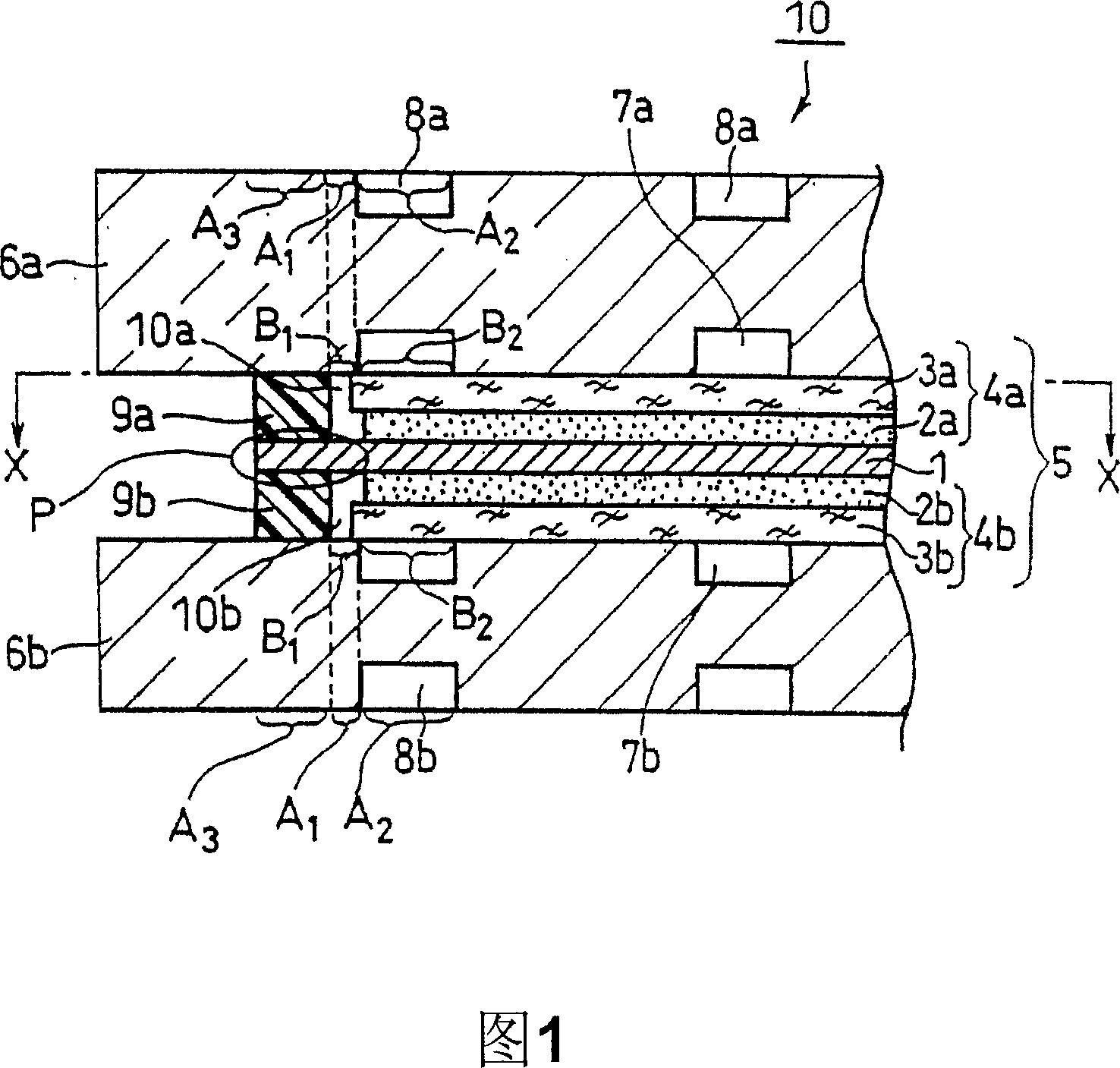

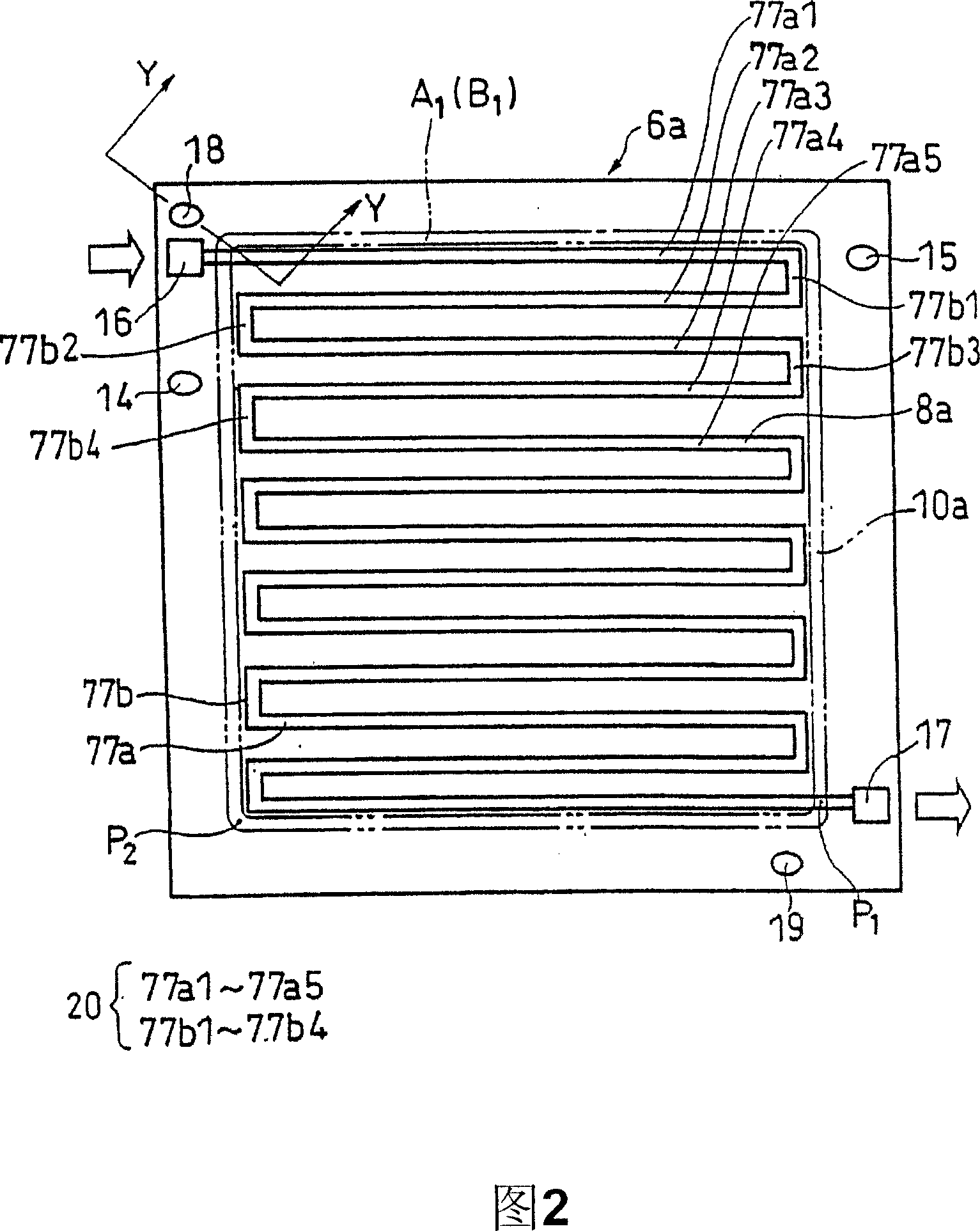

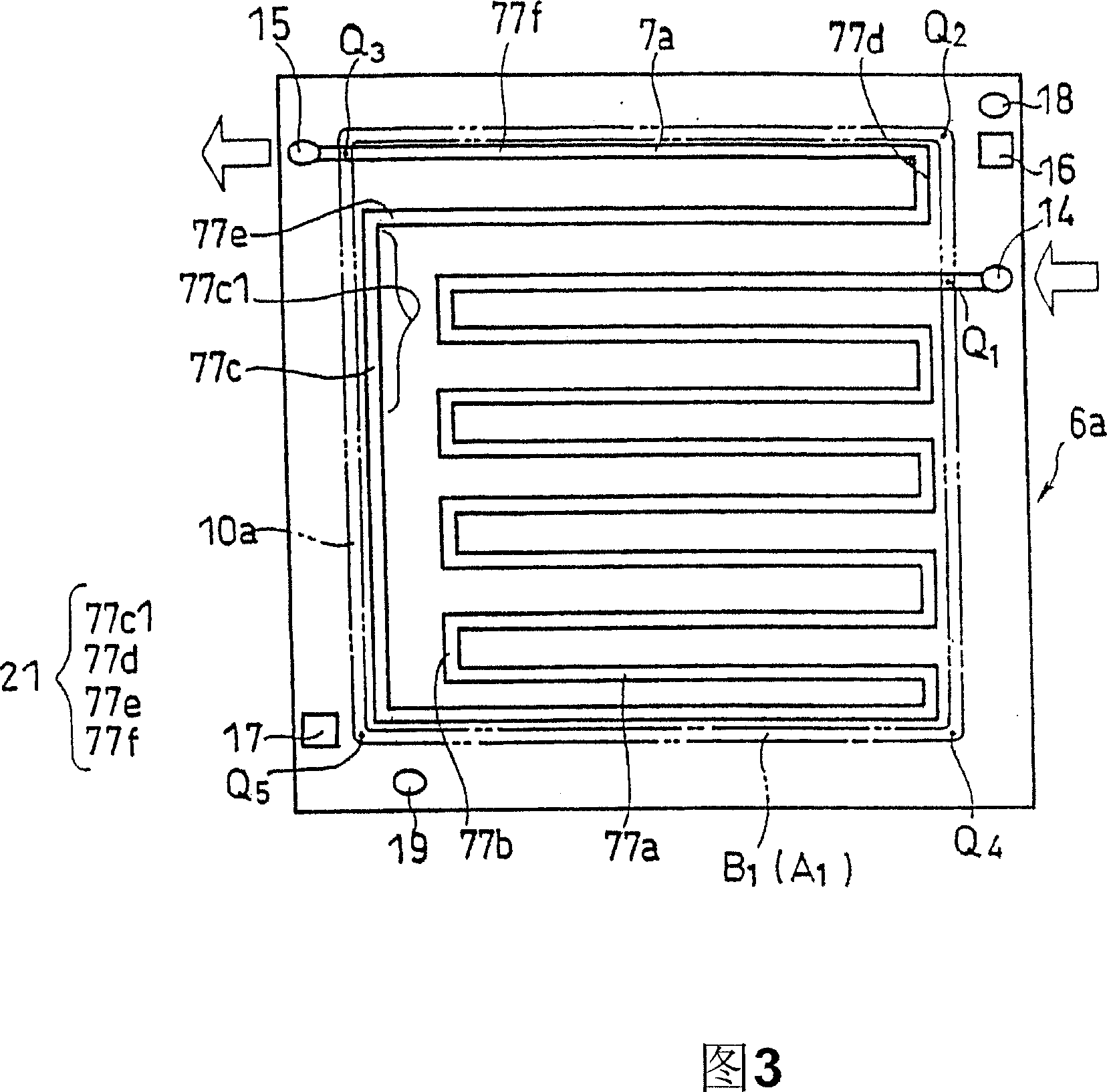

[0114] 1 is a schematic cross-sectional view of a relevant part of a polymer electrolyte fuel cell according to Embodiment 1 of the present invention, illustrating its basic structure. FIG. 2 is a front view of the main surface of the positive electrode side separator 6a of the fuel cell 10 shown in FIG. 1 viewed from the side of the cooling fluid passage 8a. FIG. 3 is a front view of the main surface of the anode-side separator 6 a of the fuel cell 10 shown in FIG. 1 viewed from the gas channel 7 a side. Fig. 4 is a front view of the main surface of the anode-side separator 6b of the fuel cell 10 shown in Fig. 1 viewed from the side of the gas channel 7b. Fig. 5 is a front view of the main surface of the anode-side separator 6b of the fuel cell 10 shown in Fig. 1 viewed from the side of the cooling fluid passage 8b.

[0115] 6 is a schematic cross-sectional view of the fuel cell 10 obtained along line X-X in FIG. 1 (with the positive electrode separator 6a removed, the membr...

Embodiment approach 2

[0209]Now, a fuel cell according to Embodiment 2 of the present invention is described. The fuel cell and the fuel cell stack (not shown) according to Embodiment 2 have the same structure as the fuel cell 10 and the fuel cell stack 30 of Embodiment 1, except for the positive electrode side separator and the negative electrode side separator, because the positive electrode side The separator and the negative side separator are replaced with different structures.

[0210] The cathode-side separator and the anode-side separator of the fuel cell according to Embodiment 2 are described below.

[0211] 11 is a front view of the main surface of the positive electrode side separator 26a incorporated into the fuel cell according to Embodiment 2 of the present invention viewed from the side of the cooling fluid passage 8a. 12 is a front view of the main surface of the positive electrode side separator 26a incorporated into the fuel cell according to Embodiment 2 of the present inventio...

Embodiment approach 3

[0239] A fuel cell according to Embodiment 3 of the present invention will now be described. The fuel cell and the fuel cell stack (not shown) according to Embodiment 3 have the same structure as the fuel cell 10 and the fuel cell stack 30 of Embodiment 1, except for the positive electrode side separator and the negative electrode side separator, because the positive electrode side The separator and the negative side separator are replaced with different structures.

[0240] The cathode-side separator and the anode-side separator of the fuel cell according to Embodiment 3 are described below.

[0241] 15 is a front view of the main surface of the positive electrode side separator 46a incorporated into the fuel cell according to Embodiment 3 of the present invention viewed from the side of the cooling fluid passage 8b. 16 is a front view of the main surface of the positive electrode side separator 46a incorporated into the fuel cell according to Embodiment 3 of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com