Method for removing powder of catalyst from catalytic cracking oil slurry

A catalytic cracking oil slurry and catalyst technology, applied in the direction of electricity/magnetic dehydration/emulsification, etc., can solve the problems affecting the processing capacity and processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The properties of the treated oil slurry are shown in Table 1.

[0018] project

value

Density (g / cm 3 ), (20°C)

1.0490

Viscosity (mm 2 / s)

80℃

170.9

100℃

53.53

saturated hydrocarbon

29.4%

Aromatics

46.0%

18.8%

asphaltenes

5.8%

Ash

0.336%

Solidifying point

+12℃

Charcoal residue

14.6%

[0019] Preparation of mixed oil: Take 64g of kerosene and 96g of FCC oil slurry to make mixed oil, take 1 wt% flocculant (polyacrylamide) and 0.8g demulsifier (FC9301) and 15.2g water to make an aqueous solution, take this aqueous solution Preheat with the mixed oil to 95°C, click and mix 50 times in the juice extractor, place in the demulsifier, and apply an electric field of 2000v / cm. Stand still for 1 hour to separate the water, pump out the lower layer of water, take the oil after removal and stir evenly t...

Embodiment 2

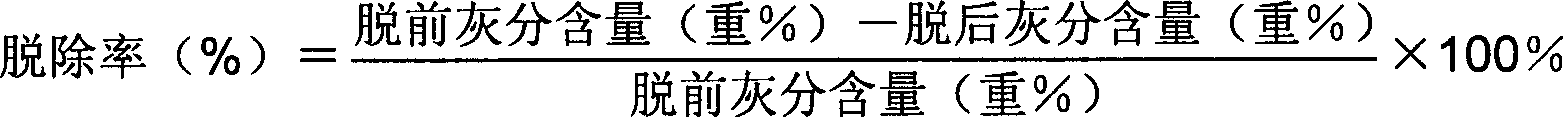

[0022] The properties of the oil slurry are shown in Table 1. Use heptane as solvent oil and FCC oil slurry to prepare mixed oil. Take 42g of heptane and 118g of FCC slurry to make mixed oil, take 6.4g of flocculant (polyacrylamide, concentration 1% by weight) and 0.8g of demulsifier (FC9301, concentration of 2% by weight) and 24.8g of water to make an aqueous solution , take this aqueous solution and mixed oil, preheat to 95°C, click and mix 50 times in a juice extractor, put it in a demulsifier, and apply an electric field of 2000v / cm. Stand still for 1 hour to separate the water, pump out the lower layer of water, take the oil after removal and stir evenly to measure the ash content. The test results are shown in Table 3. It can be seen from the test results that heptane has a better removal effect as solvent oil, and the removal rate reaches 97.3%.

[0023] Ash content (weight%)

Embodiment 3

[0025] The properties of the oil slurry are shown in Table 1. Use toluene as solvent oil and FCC oil slurry to prepare mixed oil. Mix 77.7g of toluene with 82.2g of FCC oil slurry to make mixed oil, take 6.4g of flocculant (polyacrylamide, concentration 1% by weight) and 0.8g of demulsifier (FC9301, concentration of 2% by weight) and 24.8g of water to make Aqueous solution, preheat the aqueous solution and mixed oil to 95°C, click and mix 50 times in a juicer, place in a demulsifier, and apply an electric field of 2000v / cm. Stand still for 1 hour to separate the water, pump out the lower layer of water, take the oil after removal and stir evenly to measure the ash content. The test results are shown in Table 4. From the results, the removal rate of toluene as solvent oil is 98.6%.

[0026] Ash content (weight%)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com