Method for testing insulating property of textile

A technology of heat preservation performance and detection method, which is applied in the direction of textile testing, material inspection products, material thermal conductivity, etc., and can solve problems such as inaccurate detection, slow heat dissipation of test boards, and methods for detecting fabric heat preservation performance indicators that have never been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

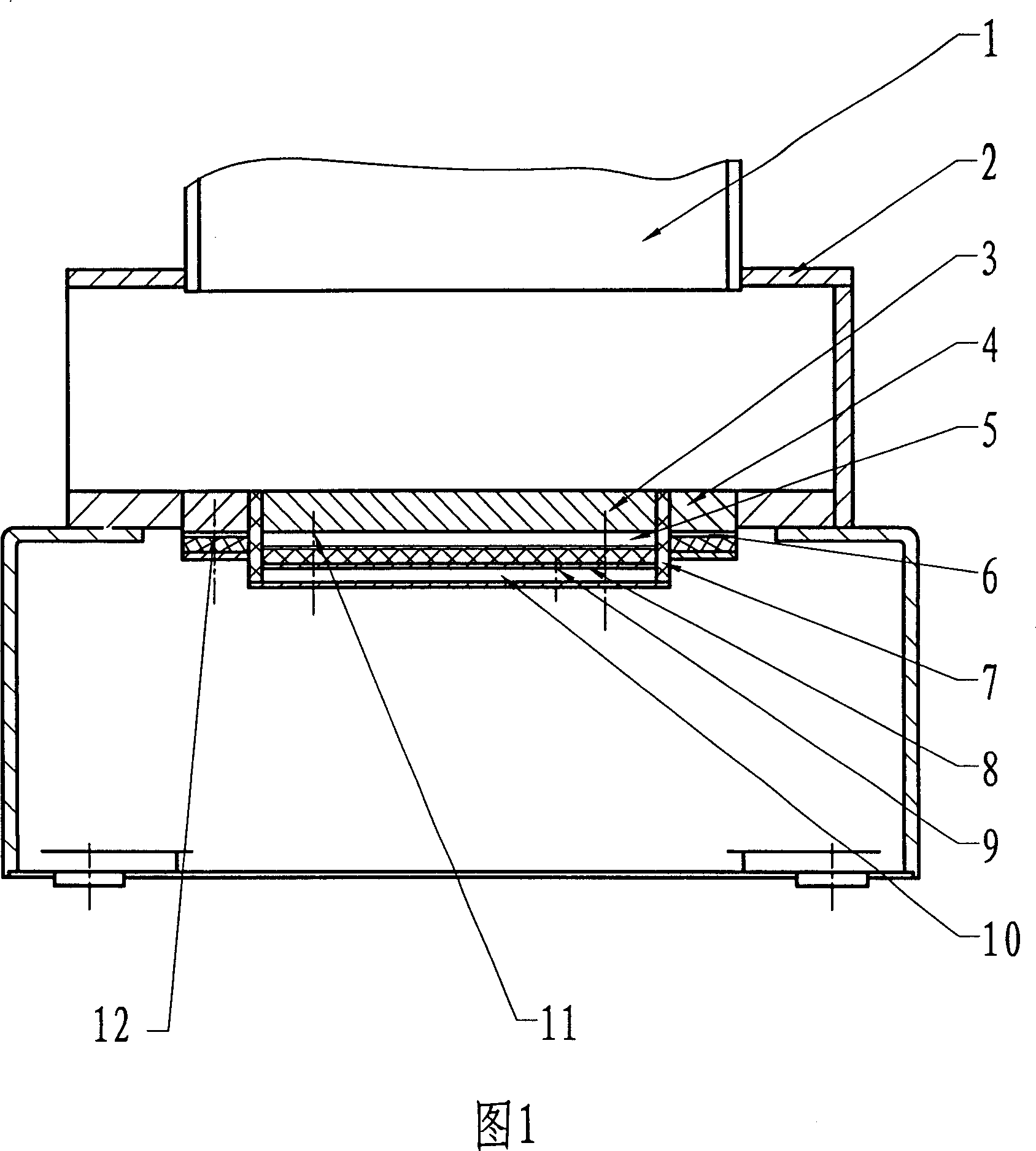

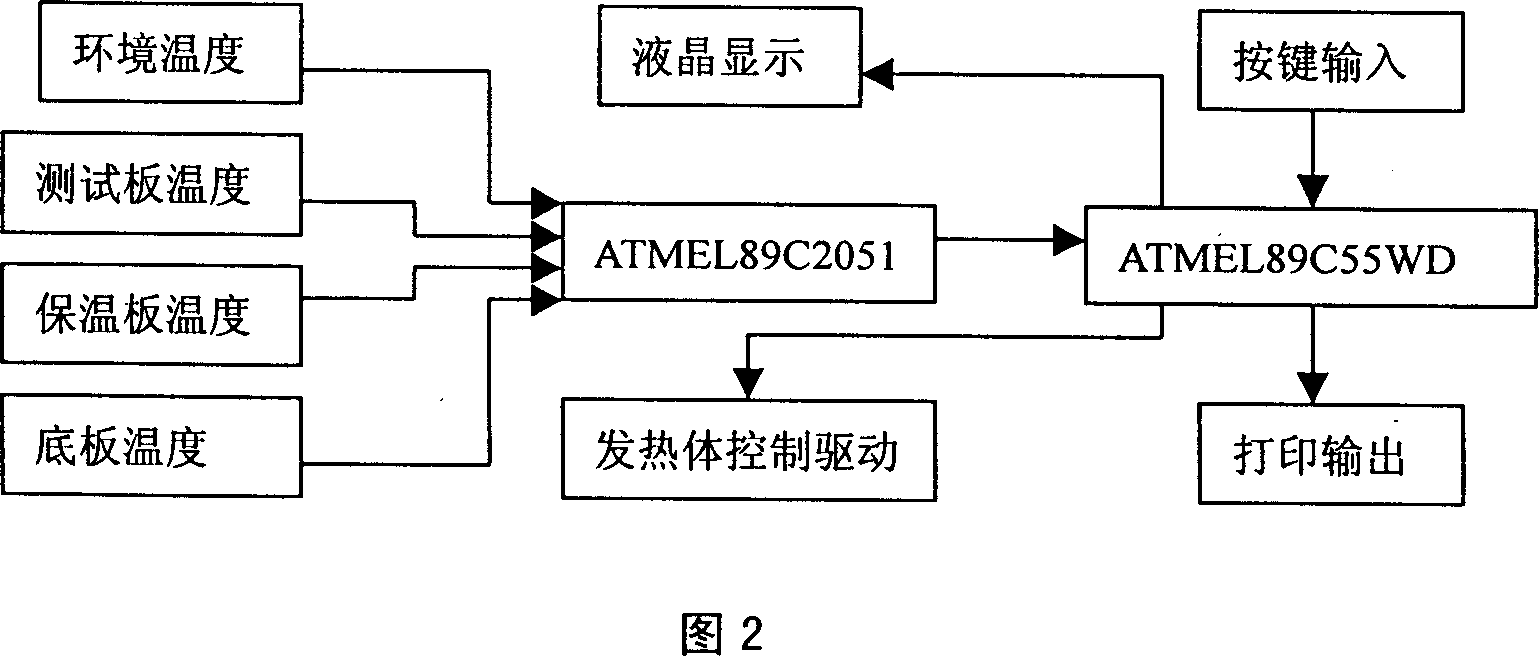

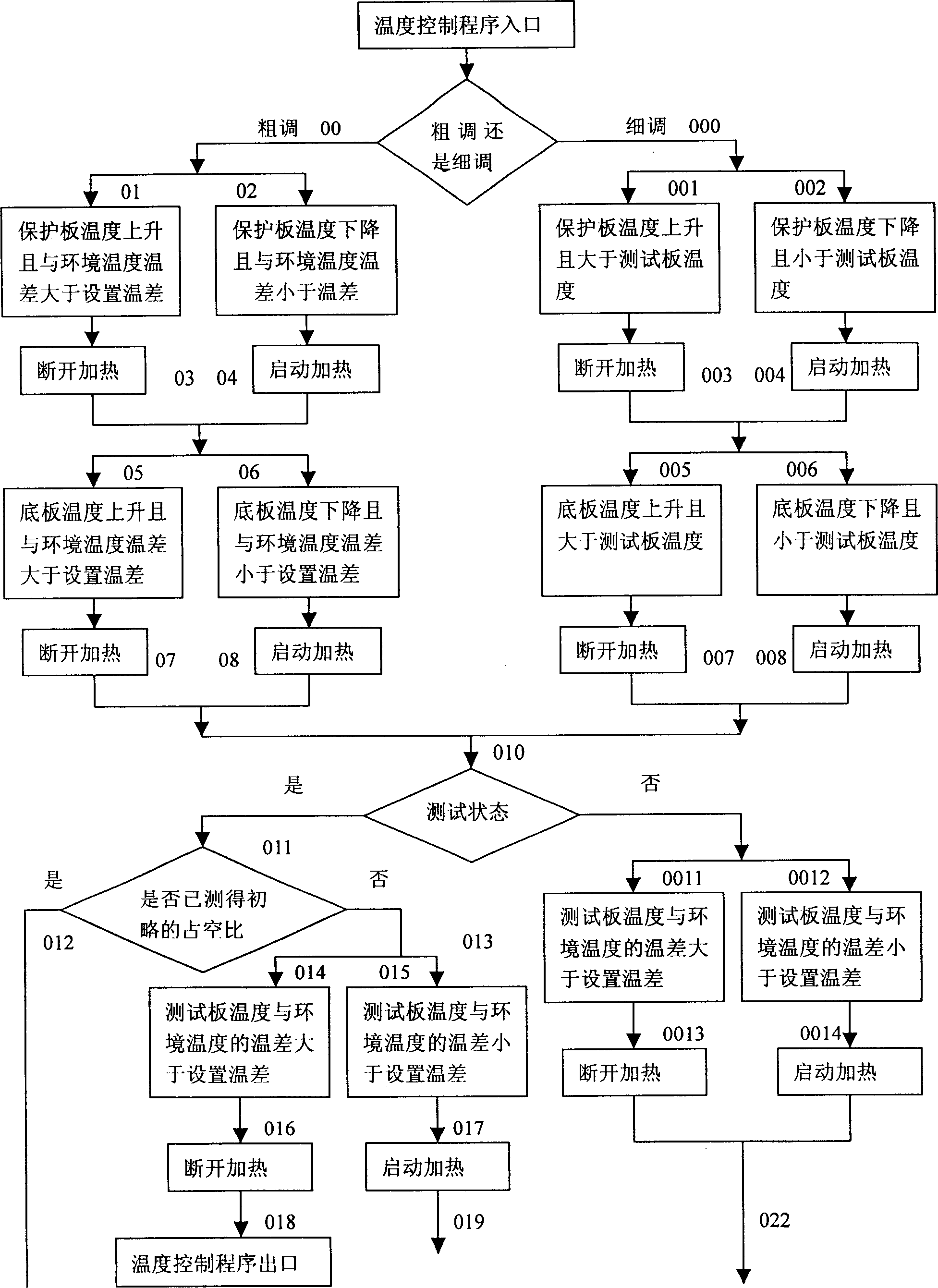

[0033] The detection method of the present invention adopts a flat heat preservation instrument as a basic test method, and calculates various data of the heat preservation performance of textiles based on thermal engineering principles and calculation formulas for material heat transfer coefficients. As shown in Figure 1, the tester is equipped with a sample plate, a protective plate and a bottom plate, and each heating plate is separated by a heat insulating material to ensure the accuracy of the test temperature. In order to protect the sample from the influence of the surrounding air, a transparent cover is installed on the periphery, the door is opened in front of the transparent cover, and a window is opened on the top. Figure 2 shows the microcomputer control system and data processing center, using single-chip microcomputer U 1 (ATMEL89C55WD) and microcontroller U 2 (ATMEL89C2051) Dual CPU control, MCU U 2 The function is to sample and read the temperature of the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com