Edible fungus drying equipment

A technology for drying equipment and edible fungi, applied in drying, food preparation, lighting and heating equipment and other directions, can solve the problems of high cost, unguaranteed finished products, environmental pollution and other problems, and achieves simple structure and cost saving. , create convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

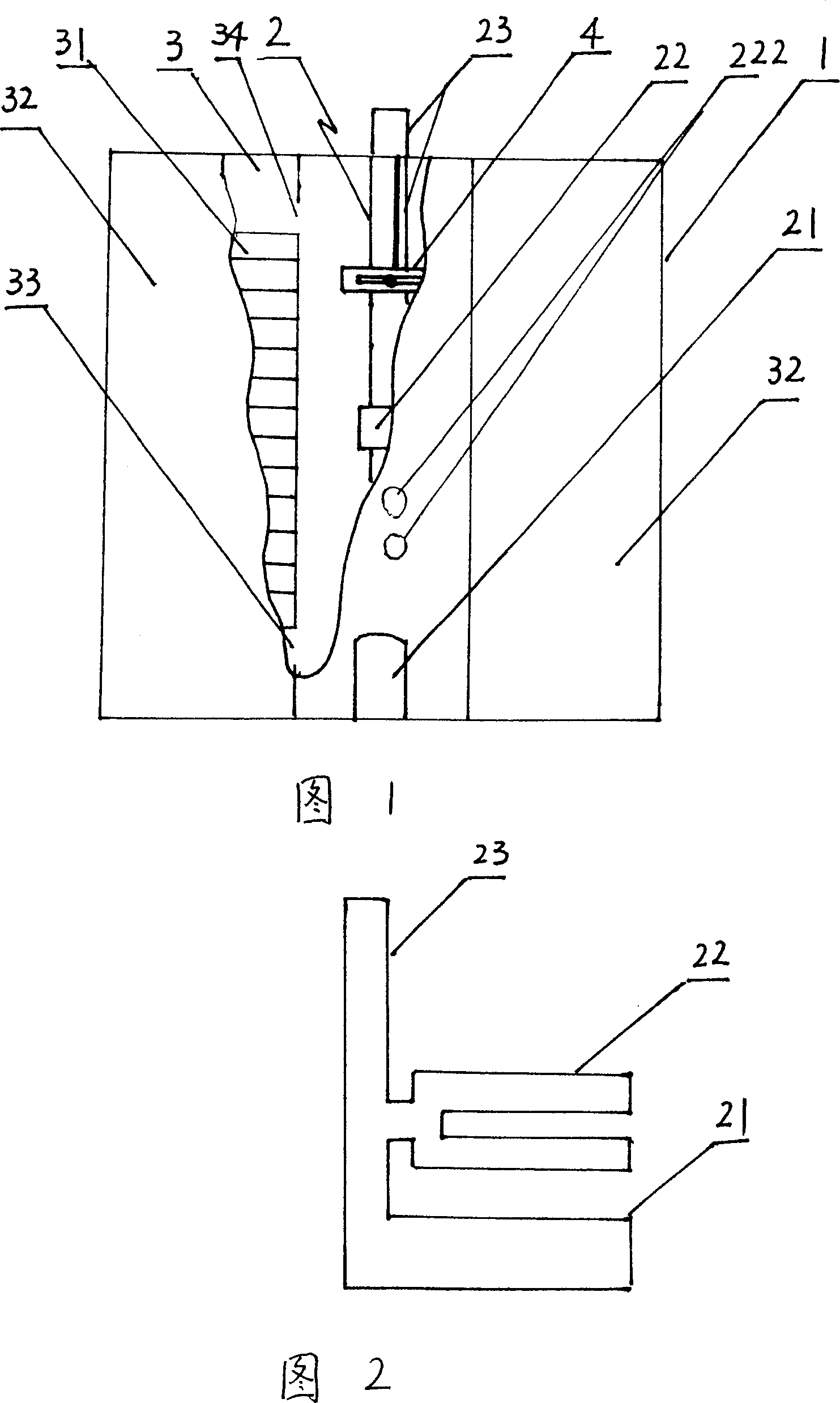

[0014] It can be seen from Fig. 1 and Fig. 2 that a kind of edible fungus drying equipment is composed of metal materials, including a casing 1, a heat-producing circulation device 2 in a closed state in the casing 1, and two sides of the heat-producing circulation device 2. The oven 3, the exhaust fan 4 with a diameter of 600 mm, and the heat production circulation device 2 are respectively composed of a burner 21, two pairs of circulation pipes 22, and a chimney 23 with an outlet at one end. One port of each circulation pipe 22 is connected to the side wall of the chimney 23 The other port 222 extends out of the shell 1, and the two sides of the heat generating circulation device 2 are respectively connected to the oven 3 through the hot air port 33, the return air port 34 and the oven partition 35, and the exhaust fan 4 is located directly above the circulation pipe 22 through the exhaust fan hanger 41 is mechanically connected to the top end of the inner surface of the hous...

Embodiment 2

[0016] It can also be derived from Fig. 1 and Fig. 2 that a kind of edible fungus drying equipment is made of building materials such as bricks and cement, and includes a shell 1, a heat-producing circulation device 2 in a closed state in the shell 1, The oven 3 and exhaust fan 4 located on both sides of the heat-producing circulation device 2 are respectively composed of a burner 21, two pairs of circulation pipes 22, and a chimney 23 with an outlet at one end. One port of each circulation pipe 22 is connected to the chimney 23 The side wall is connected, and the other port 222 protrudes out of the shell 1. The left and right sides of the heat-producing circulation device 2 are openly connected to the oven 3. There is no structure of the hot air port 33 and the return air port 34, and there is no oven partition 35. , The exhaust fan 4 is suspended directly above the circulation pipe 22 on the inner surface of the housing 1 .

[0017] During use, open the chamber door 32, put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com